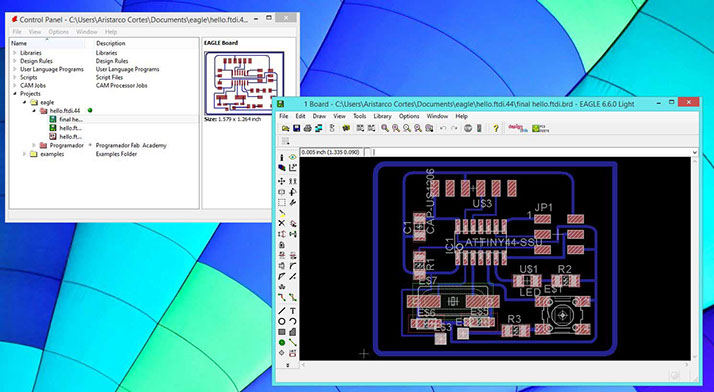

I don't have any electronics background so the first thing I did was learning how to design a board with Eagle CAD software.

At the end it was pretty easy to use it. I did my own FAB ISP design to make it in the Modela MDX 20 Machine

We first tried with Dr. Engrave, the software that comes with the Modela.

Results were unsatisfactory since the program is not reliable. It could mill some lines pretty well but for some reason other lines were not milled properly.

Fab Modules was very difficult to install. It did not run in a Virtual Machine, we had to format a computer and instal Ubuntu. After many efforts we finally got Fab Modules up and running.

We made several tests in order to find the right parameters for the modules.

When we checked the tool inventory we found out that we did not have the 1/64 tool, it seems some administrative problem finding the tool supplier in Mexico and in exchange we received many other sizes.

We had a cnc engraving bit tool so we tested it.

We tried many parameters to use it with Fab Modules.

Results were surprisingly good. We were testing and decided not to move the board, so we did not cut the border. We will work on this issue.

You can see the Modules parameters we used with the triangular tool

A great news using this tool is cost. The 1/64 cutting tool cost around 50 Dollars + tax + Shipping cost.

The cnc engraving bit tool costs $2 USD on ebay, free shipping

Results are impressive. Fab Modules seems to make an interpretation of the circuit and very precisely cuts the board.

Resolution is outstanding. I need to make a very small gear for my final project and I think Fab Modules will be a great tool.

Welding surface mount components was a completely new endeavor for me.

We worked together as a group in Fab Lab Puebla. In our group there is an electronic engineer who teached us how to properly weld, but since I have very little welding experience it was very difficult.

Finding surface mount components in Puebla, Mexico was very difficult. We had to use some through hole components.

The ATTINY 44 was not available and we had to buy them in Guadalajara and make them sent to us.

This is a good learning for future lessons.

Learnings:

Fab Modules is a great software but very difficult to set up, there is an area of opportunity in there.

Modules seems to recognize the circuit and gives great precision to the cut. On the contrary Dr. Engrave does not fulfill precision parameters

It is hard to find surface components in Mexico, it is important to plan ahead in order to buy with time the parts

We did not have the 1/64 cutting tool so we used a triangular cutter, very unexpensive and easier to find.

A circuit like FAB ISP with traditional methods (Ironing, Ferric chloride, etc) will take about 1.5 hours, with the Modela in 9 minutes it is done.