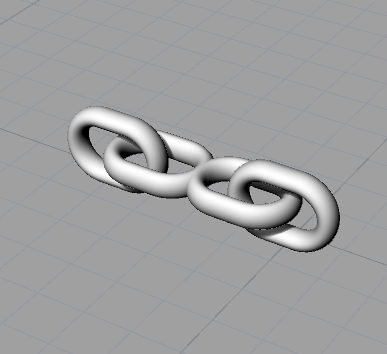

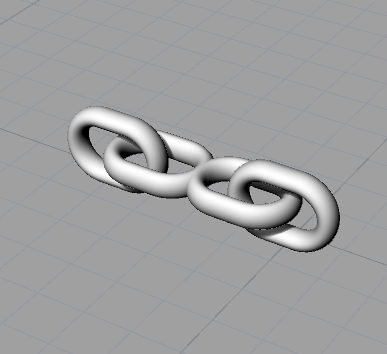

Hook and chain thing from molding and casting week

Hook and chain thing from molding and casting week

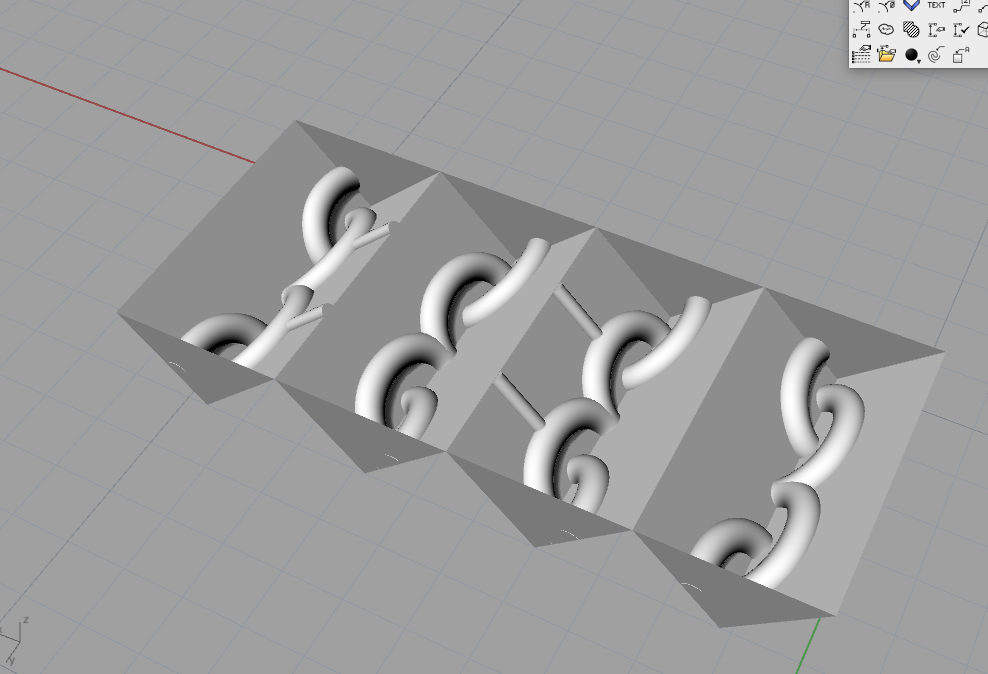

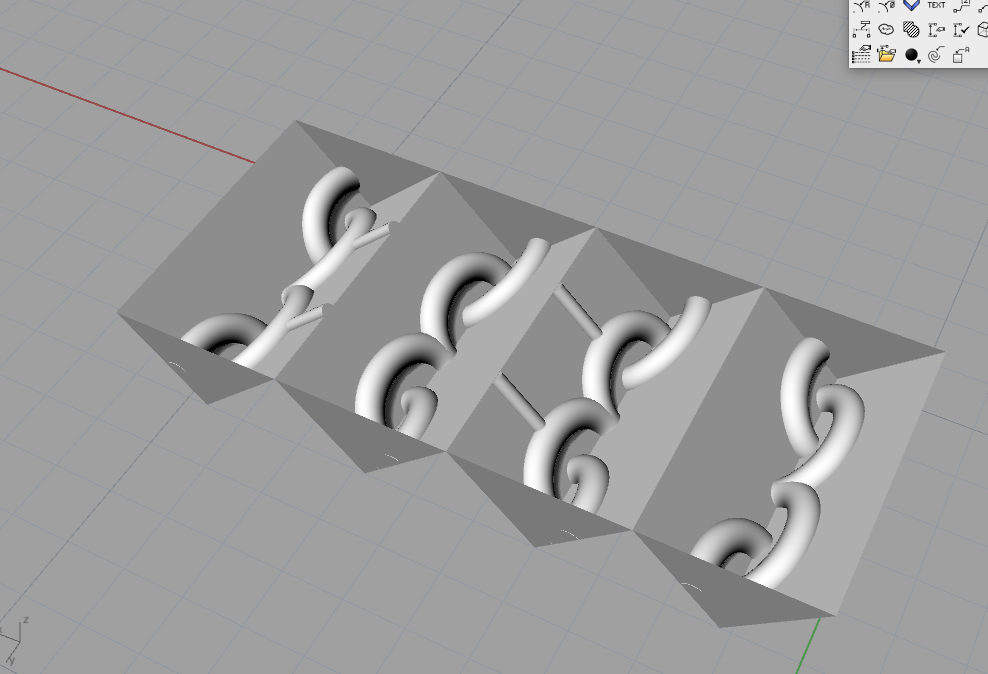

four prart mold parts progress shot

four prart mold parts progress shot

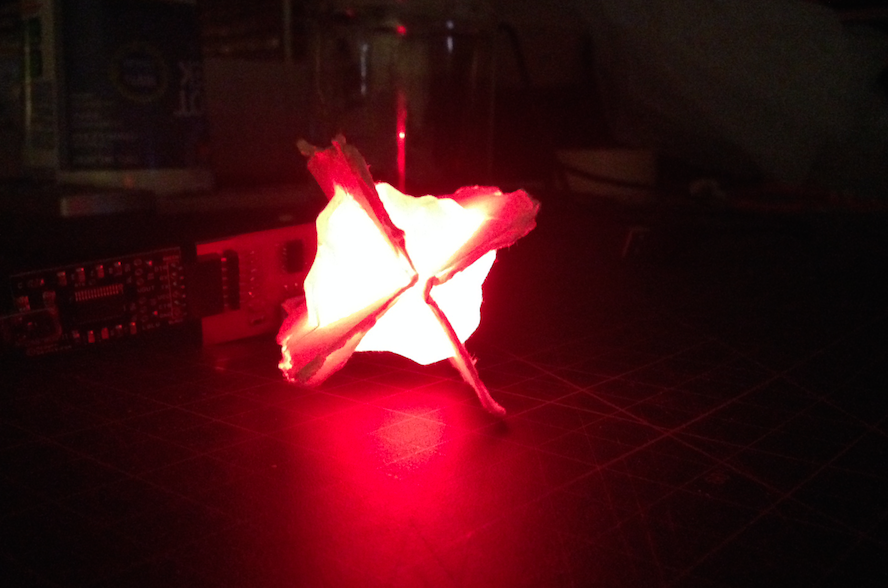

My final project for fab Academy 2015 is going to be a haning lamp. The lamp will suspended from the ceiling by chain of cast hydrostone links. A paper skin will cover a lazer cut press-fit wood skeleton. Color and intensity of the light will be controlled by capacitive sensor input and a micro controller. The light will be produced by High Power RGB and White LEDs.

Countless people have made lamps out of every imaginable material, Lamps are fundamental design objets going back thousands of years. It's not a new idea and thats part of what if find exciting about the project.

Mill a 4 part mold out of stacked MDF on the Shop-bot. Use PartWorks3d for file prep and 1/4inch straight zero spiral for milling. Smooth-On PMC 121/30 Liquid Rubber. Measure and bag amount needed per chain link. Mix with water in bag and squeeze out though hole in bag into mold. This will take a long time because of the wait time for each part to dry. Make multiple molds asap and keep them in rotation.

Hook and chain thing from molding and casting week

Hook and chain thing from molding and casting week

four prart mold parts progress shot

four prart mold parts progress shot

Simple press-fit sphere made from quarter inch birch plywood. Light, durable easy to assemble structure, hopefully able to take a drop. Adhesive backed copper foil will turn the press fit pieces into capacitive sensors used to control the light.

I will source majority of components for the fab inventory the Fab Inventory. Cotton rag paper, printing ink and high power LEDs are the only componets not in the invetory. I estimate the I will use ~$40 in materials per lamp. Here is inventory of parts and materials needed, it is a work in progress. Final Project Inventory

Frank Stella dimensional printmaking