07 Computer-Controlled Machining

Table Design

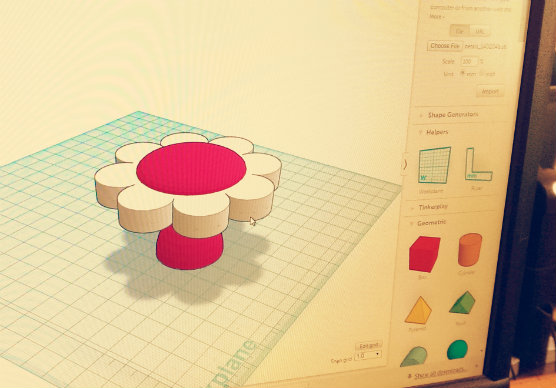

I started bt creating flower table design in tinkercad.

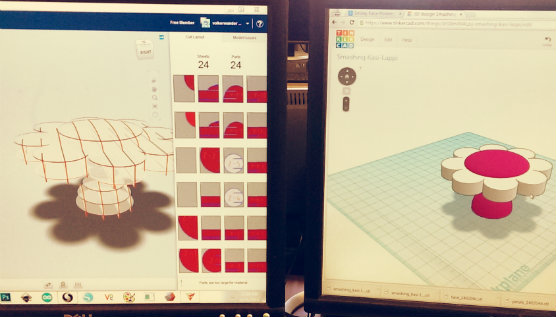

I then used 123D Make to turn the 3D model into a 2D cut plan for the CNC Machine.

I then used 123D Make to turn the 3D model into a 2D cut plan for the CNC Machine.

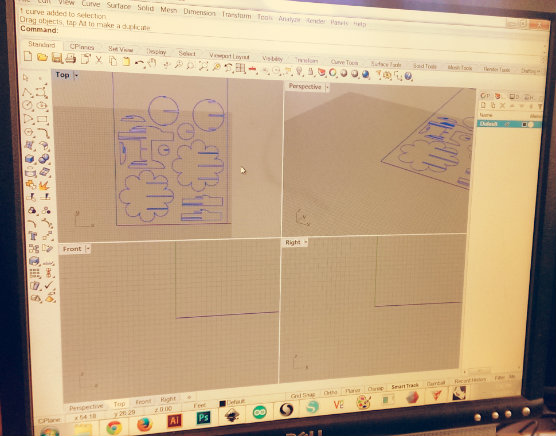

I was then able to import the cut file into Rhino where I had to edit the file and add drill points at every inner corner so that the pieces would easily slide all the way together. This isn't a perfect solution but it does take care of the fact that our cutting bit has a certain radius and can't cut all the way into corners. At this point the file was ready for the CNC Machine.

I was then able to import the cut file into Rhino where I had to edit the file and add drill points at every inner corner so that the pieces would easily slide all the way together. This isn't a perfect solution but it does take care of the fact that our cutting bit has a certain radius and can't cut all the way into corners. At this point the file was ready for the CNC Machine.

CNC Time

So it was off to the hardware store for some 3/4 inch MDF board.

Because our Fab Lab doesn't have large CNC Machine we had make friends with the architecture students who have a facility next door to us. They were nice enough to let use their machine for a weekend to get our projects done.

Because our Fab Lab doesn't have large CNC Machine we had make friends with the architecture students who have a facility next door to us. They were nice enough to let use their machine for a weekend to get our projects done.

We used there C.R. Onsrud 98C machine for our projects. The work flow was straight forward as they usually use Rhino for their projects and had a presets ready to go for generating files that cut MDF on the machine. I used a 1/2 inch cutting bit for the project.

All I had to do was load up the file and hit run and I had a new flower shaped table.

All I had to do was load up the file and hit run and I had a new flower shaped table.

The hardest part was probably sanding all the edges. MDF cutts pretty rough and makes a mess when you sand it. But after it's sanded it actualy looks quite good.

The hardest part was probably sanding all the edges. MDF cutts pretty rough and makes a mess when you sand it. But after it's sanded it actualy looks quite good.

After sanding I just had to solve the puzzle of how to slide the pieces together.

After sanding I just had to solve the puzzle of how to slide the pieces together.

I think the final product looked pretty great. Though it would have been more stable if solid wood was used and if there were two center posts instead of one.

I think the final product looked pretty great. Though it would have been more stable if solid wood was used and if there were two center posts instead of one.

Design Files

Original 3D model of the table can be downloaded here.

Rhino file of exported 123DMake design can be downloaded here