Week

7: Molding & Casting

Week

7: Molding & Casting

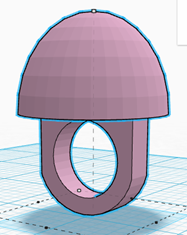

This

week our assignment was to design a 3D mold, machine it, and cast parts from

it. I envisioned creating a clear resin ring with a large carpenter bumblebee

nestled inside of my design. I built upon a 3D printed ring I had previously made

in Tinkercad.

This

week our assignment was to design a 3D mold, machine it, and cast parts from

it. I envisioned creating a clear resin ring with a large carpenter bumblebee

nestled inside of my design. I built upon a 3D printed ring I had previously made

in Tinkercad.

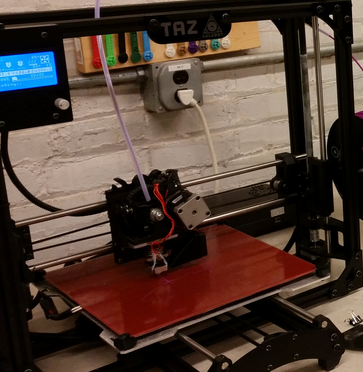

†I then 3D printed my ring using

our labís Taz printer with blue PLA.† Using the ring, I was able to make a silicon

rubber mold. The Oomoo brand was easy to use, and

quick to cure! This mold was very flexible. I also 3D printed two molds.

My experiment with the 3D molds produced a bouncy silicone rubber ring, that

wasnít perfectly lined up! Then I poured a liquid plastic, Smooth-On, into my

3D printed mold, without anything to prevent the two plastics from fusing

together. The liquid plastic set & hardened very quickly, within 10

minutes. The container we poured it from was noticeably hot, also! I decided to

go back  to

Oomoo with my ring sliced, and 3D printed in

to

Oomoo with my ring sliced, and 3D printed in  halves(NETFAB

STL file) I used epoxy resin this time and experimentally stuck a bee into the Oomoo mold. This did not produce a very nice effect once

the ring cured a day later. The layers in the plastic diffused the outer part

of the ring, the open air side cured smooth and crystal clear! I will have to

sand my 3D printed ring and start over, this time lining up pegs so the two

halves will be as seamless as possible!†††††

halves(NETFAB

STL file) I used epoxy resin this time and experimentally stuck a bee into the Oomoo mold. This did not produce a very nice effect once

the ring cured a day later. The layers in the plastic diffused the outer part

of the ring, the open air side cured smooth and crystal clear! I will have to

sand my 3D printed ring and start over, this time lining up pegs so the two

halves will be as seamless as possible!†††††

Our

fab lab group was fortunate enough to have a friend  teach

us sand casting at his forge. In preparation I lasered

some 1/8Ē birch wood arrows.

My plan was to create metal arrows I would be able to hang up and make a wind

chime. I learned many things about sand casting. For one, the sand mixture for

the molds contains not just sand, but clay & motor oil too. You must be

very precise making the hole and bridge that the liquid metal is poured into.

The aluminum takes about an hour to heat up to pouring temperatures. Once the

metal has been poured into the molds, fifteen minutes later you can break it

open, carefully pick up the cast, and cool it off in water. Then, you have to

break the bridge of metal between your two shapes, and grind off any

imperfections. My thin, delicate arrows turned out much better than expected! †††††††††††

teach

us sand casting at his forge. In preparation I lasered

some 1/8Ē birch wood arrows.

My plan was to create metal arrows I would be able to hang up and make a wind

chime. I learned many things about sand casting. For one, the sand mixture for

the molds contains not just sand, but clay & motor oil too. You must be

very precise making the hole and bridge that the liquid metal is poured into.

The aluminum takes about an hour to heat up to pouring temperatures. Once the

metal has been poured into the molds, fifteen minutes later you can break it

open, carefully pick up the cast, and cool it off in water. Then, you have to

break the bridge of metal between your two shapes, and grind off any

imperfections. My thin, delicate arrows turned out much better than expected! †††††††††††