Homework

- Our homework was to design and make a 3D mold (~ft2), and produce a fiber composite part in it. I decided to design a boat that could possibly be used in my final project.

Challenges

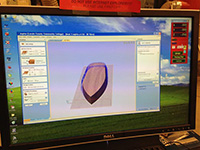

- Designing using a 3D CAD program is a struggle for me, but I was able to create a simple boat.

- Figuring out the speeds and feeds for the ShopBot was time consuming and required lots of research.

- Aspire and creating acceptable toolpaths

- The 1/2 inch tool was not center cutting.

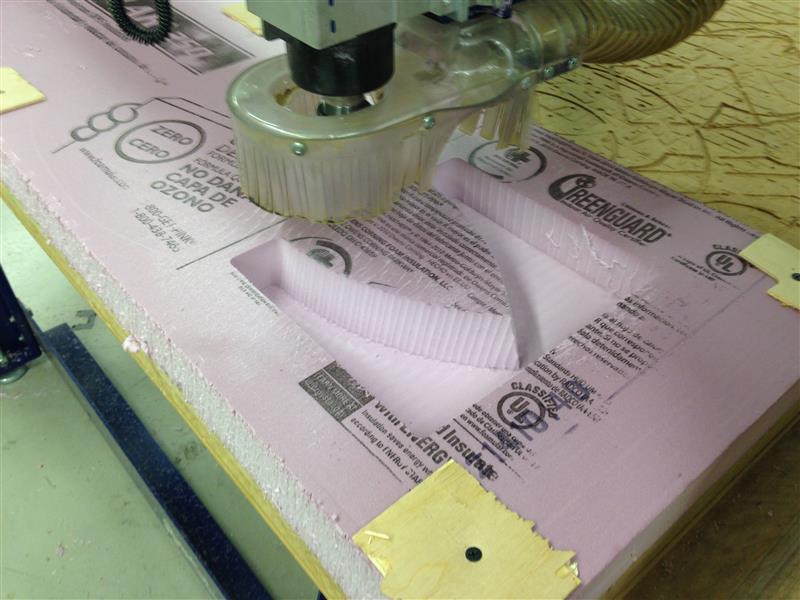

- Okay, it's a couple weeks later and I am still struggling with milling the foam mold on the Shopbot. Everyone in the FabLab, anyone who knows anything about that machine has been working, researching, trying and we don't have a solution. I have the design, I just can't move on to the composite phase. Plan B?

Designing and Milling

- I designed my boat in AutoCAD. I then converted it to an stl file, set the toolpaths in Aspire, and sent the job to the ShopBot. I used 1 and 7/8 inch pink foam AND 2 layers of that will be glued together.

- Correction: I WAS going to do that, but after weeks of issues, I just milled my boat out of 2 inch pink foam and it's just 1 layer. I used a 0.5" flat endmill. The speed is 12,000 rpm and the feed rate is 100 in/min.Thanks Scott and Tim for all your hard work on the ShopBot updates!!!! We had success, finally!.

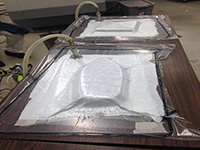

Making the Composite

Design Files

Boat stl

Boat dwg