Week 9: Molding and Casting

3.25.2015 - 3.31.2015

Lecture Notes:

Homework:

- Design, mill, and cast a three dimensional part

Resources:

- Fab

Academy Handbook

- Roland

MDX-20 Specifications

- SRP

Player Software

- Smooth On - Smooth Cast 300 Series

- Smooth

On - Smooth Cast 300 Series Tech Bulletin

- Smooth On - PMC-121

Files:

Project:

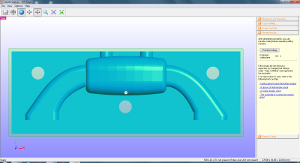

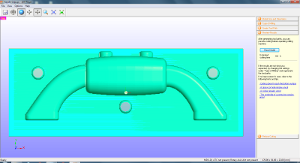

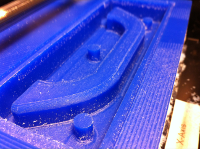

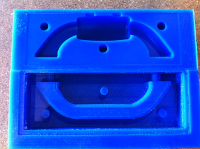

For this project I wanted to investigate casting parts with dissimilar materials. I opted to create two, two-part molds (one positive and one negative) and use them sequentially to cast a rigid handle with integral soft grip. The two-part casting process utilized flexible and rigid molds.Design:

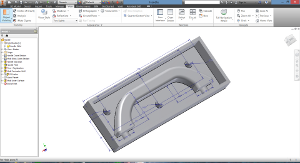

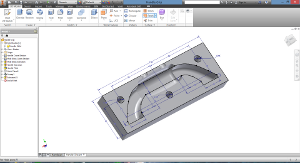

AutoDesk Inventor Professional - Student Edition was used to parametrically design separate handle bar (positive) and handle grip (negative) molds.The handle assembly was designed to be symmetrical to reduce the number of unique mold halves. The total number of milled parts was reduced from four to three by using independent pins (acrylic rod) to register the handle bar mold halves. One mold with male pin forms replaced separate male and female versions of the mold.

|

|

The scale of the handle and the handle's features were influenced by 1) the scale of the adult human hand, 2) the cutting envelope of the MDX-20 milling machine 8 inch x 6 inch x 2.375inch (203.2mm x 152.4mm x 60.5mm), 3) 0.125 inch (3.175 mm) end mills, and 4) the maximum cutting depth of those end mills. Maximum feature depth for either mold was limited to no more than 20mm.

Dual ports were incorporated into each mold to independently fill and vent the mold cavities.

Tool Path:

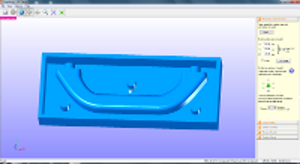

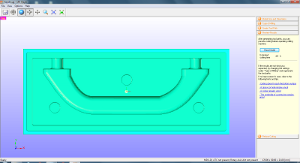

Roland SRP (Subtractive Rapid Prototyping) Player software was

used to tool path the two mold designs using machinable

wax.

|

|

|

|

Cutting Parameters

| Property |

Roughing |

Finishing |

| Feed Rate |

900 mm/min | 900 mm/min |

| Spindle Speed |

6500 RPM |

6500 RPM |

| Cutting In

Amount |

1.00 mm |

0.0118 mm |

| Path Interval |

1.59 mm |

0.0118 mm |

| Finish Margin |

0.10 mm |

0.0 mm |

Milling & Casting:

The following image sequence documents the steps taken during

the sectioning, mounting, surfacing, milling and

molding processes.

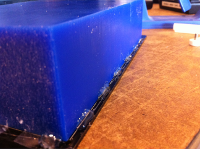

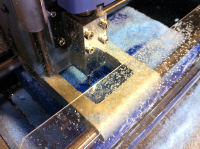

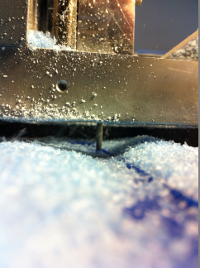

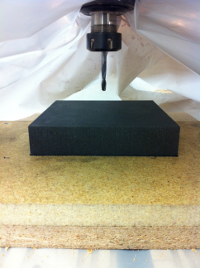

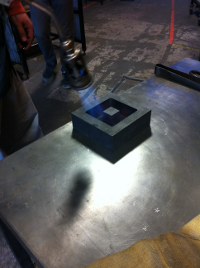

The 8 inch x 6 inch x 2 inch (203 mm x 152 mm x 51 mm) wax

blank's irregular surfaces required the use of double-sided tape

supplemented by hot glue to fixture it to the MDX-20's work

plate. Once mounted, the blank was surfaced with the

MDX-20 prior to zeroing the end mill and milling the molds.

|

|

|

|

|

|

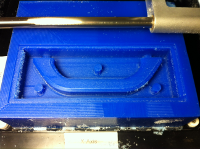

The 0.125 inch (3.175 mm) square end mill used to rough and

finish the handle mold produced a roughened surface and

discernible tool marks. One half of the handle grip mold

was nested on the same wax blank and roughed and finished with a

0.125 inch (3.175 mm) ball nose end mill with excellent surface

finish and no appreciable tool marks.

Smooth On PMC 121/30 wet urethane rubber was used to mold the

wax handle. Mold release spray was used to supplement the

release agent already present in the urethane and packing tape

was used to seal the mold edges excluding the holes.

|

|

|

|

|

|

|

|

|

The handle was cast multiple times using Smooth-On 305.

The first cast handle showed significant porosity and was cast

without the aid of a vacuum and only agitating the mold.

The flash was limited to a portion of the mold's interior

region. The second and third handles were cast under vacuum

using an off-the-shelf rigid vacuum storage container

system. The larger flash of these handles required

unsealing the vacuum container and topping off the mold

periodically as the resin level dropped in the mold

cavity.

The mold was not clamped during any the casting trials out of

concern the external force would potentially distort the mold

and handle form.

|

|

|

|

|

|

|

|

Casting quality improved with the following steps:

- Following the specified Part A to Part B mass ratio

- Allowing the mixed casting resin to rest prior to pouring

- Sealing the mold edges

- Rocking the mold

- Using a vacuum chamber

Porosity was decreased but not entirely removed over the three

casting trials. Bubbles within later castings were

generally finer than early castings but still found throughout

the handle. The mass of the cast and trimmed handles

increased by the third casting.

Other improvements to the mold and casting process might

included:

- Integral raised lip or bead around the mold's mating surfaces for sealing and alignment

- Clamping the mold halves during casting

- Larger sprue

Assembly of the urethane mold and subsequent handle castings

revealed asymmetry in handle model which prevented casting the

grip using the rigid female wax mold.

2D CAD / Glass Casting:

During Fab Academy weeks 6 and 7 I milled two high-temperature glass molds as part of a separate project.

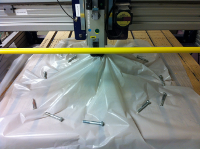

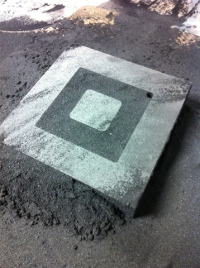

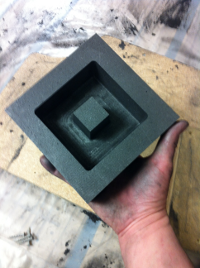

The following images document the steps taken during the

mounting, milling, and casting processes. Tulsa

Glassblowing Studio performed the glass casting.

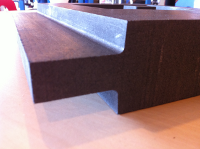

The molds were designed as 2D files using VCarve Pro 7.0,

tool-pathed for the Shopbot PRS Alpha 96, and milled from 2 inch

(50.8 mm) medium-grain graphite using a 0.25 inch (6.35 mm)

square end mill and a 0.5 inch (12.7 mm) to 0.25 inch (6.38 mm)

tapered ball end mill. The 3 degree taper and ball end of

the second end mill provided a mold draft and fillet

respectively. The bulk of the mold cavity was pocketed

with the square end mill offset inward from the mold

edges.

The tapered ball nose end mill was used with a pocketing

toolpath (rather than profile toolpath) to mill the mold to its

final dimensions as a precaution against chipping. A

profile toolpath with a lead in could have been used to

accomplish the same effect. The square end mill was used to

remove any remaining tool marks left by the tapered ball nose

end mill on the mold's lower surface.

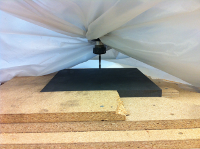

In each case a tightly fitting pocket or 90 degree corner

aligned with the Shopbot's machine axes was milled into scrap

particle wood to fixture and locate the graphite blocks.

In place of vacuum dust collection, plastic tarp was placed

beneath the particle board fixtures and fastened around the

spindle's body to contain the graphite dust. The larger of

the two molds was milled from both sides to include handles

along two edges.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|