Week 8: Computer-Controlled Machining

3.18.2015 - 3.24.2015

Lecture Notes:

Homework:

- Mill a large project

Resources:

- Fab

Academy Handbook

- Vectric V Carve Pro: http://www.vectric.com/products/vcarve-pro.htm

- Shopbot

Feed and Speed Chart

Files:

Acknowledgements:

Many thanks to Andrew, Brandi, Nathan, and Igor for their

assistance during assembly.

Project:

Plywood comprised the scooter's frame, gate hinges comprised the steering column, and wheelbarrow wheels and tires were used for wheels. Hex bolts, threaded rod, wood screws, lag screws, tee nuts, and hinges comprised the remaining hardware.

Design:

I designed glued and fastened butt and dado joints along with

laminated beams for the scooter's frame rather than elaborate

finger joints, snapping/locking joints, or living hinges.

Flush edges, pre-drilled holes, counter bored holes, and slots

facilitated aligning and assembling the parts.

Factors that influenced the scale of the scooter

included: 1) the scale and position of the rider, 2)

plywood sheet dimensions, 3) engine dimensions, and 4) wheel

dimensions. While I did not intend to motorize this

particular project, I did allow space for a rear wheel sprocket

and chain transmission within the scooter's design.

I designed the scooter to have modular sub-assemblies that

could be independently redesigned and revised without affecting

the remainder of the frame. The scooter's five

sub-assemblies: 1) platform, 2) seat, 3) steering column,

4) steering post, 5) handle bars were joined with bolted

connections.

Scooter parts were designed for 0.719 inch (18.25 mm) 5-ply

poplar plywood and drawn and tool pathed using VCarve Pro 7.0.

Consideration was given to anticipated principal loads,

ply orientation within parts, sub assembly modularity, fastener

access, driver ergonomics, power plant and transmission

elements, and part nesting. The scooter was designed

around 95th percentile adult male body dimensions.

| Property |

Down-Cutting 0.25 inch End Mill |

Plungeable Roundover End Mill |

Up-Cutting 0.25 inch End Mill |

| Dimensions |

0.25 in (6.4mm) |

0.375 in (9.5mm) minor 1.375 in (34.9mm) major |

0.25 in (6.4mm) |

| Flutes |

2 |

2 |

2 |

| LOC |

2 in (50.8mm) |

0.75 in (19.1mm) |

2 in (50.8mm) |

| Pass Depth (Z) | 0.25 in (6.4mm) |

0.375 in (9.5 mm) |

0.25 in (6.4mm) |

| Step Over

(XY) |

0.125 in

(3.2mm) |

0.25 in (6.4 mm) |

0.125 in (3.2mm) |

| Spindle Speed | 12K RPM |

10K RPM |

12K RPM |

| Feed Rate

(XY) |

3 in/s (76.2 mm/s) |

2 in/s (50.8 mm/s) |

3 in/s (76.2 mm/s) |

| Plunge Rate

(Z) |

1 in/s (25.4 mm/s) |

1 in/s (25.4 mm/s) |

1 in/s (25.4 mm/s) |

Three tools, eight cut files, twenty nine separate tool paths,

and approximately 2 1/3 sheets of plywood were required to

fabricate the scooter frame. All toolpaths (drilling,

pocketing, and profiling) were initiated with the down-cutting

end mill and cut to a shallow depth. All through-sheet

tool paths were completed with an up-cutting end mill. By

using the two tools in this sequence, the part edges were smooth

and splinter-free. Parts profiled with the round over end

mill (seat and handle bars) were milled without tabs and held in

place with wood screws.

Milling & Assembly:

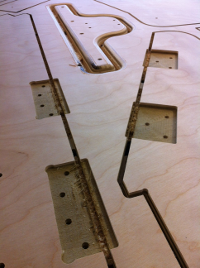

The following sequence of images illustrate the Scooter's

milling and assembly steps.

The scooter parts was assembled in the following order:

- Platform (lower sheet, sides (with tee nuts) and internal

webs, rear wheel, brake pedal, upper sheet)

- Steering Post

- Steering Column

- Seat

- Handle bars

- Kickstand (optional)

The steering post and column sub assemblies should ideally be

constructed simultaneously to permit the insertion of both ends

of the hinges into their respective pockets and shimmed with

washers where necessary.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|