Week 10: Input Devices

4.8.2015 - 4.14.2015

Lecture Notes:

Homework:

- Design a micro-controller board with a sensor and measure

the sensor's output

Resources:

- Fab

Academy Handbook

- Fab Modules

- Adafruit

Eagle Component Package Tutorial

- SparkFun Eagle SMD Footprint Tutorial

- Instructable

Eagle Custom Library Part Tutorial

- Arduino Language Reference

- Atmel

ATtiny 45 Datasheet

- Vacuum

Sensor, Vacuum

Sensor Datasheet

Files:

Acknowledgements:

Many thanks to Andrew Harmon for his guidance on this project.Project:

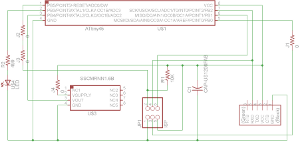

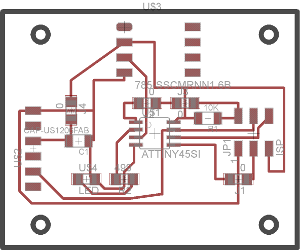

For this project I constructed a vacuum sensor circuit based on an ATMel ATtiny 45 micro-controller.Design:

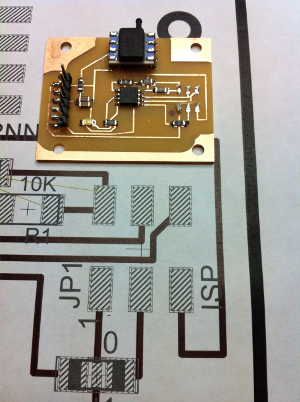

The vacuum sensor board was design using Eagle CAD. In order to mount the vacuum sensor I first needed to create a new part footprint and add it to Eagle part library. Remaining footprints for components such as the ATtiny 45 were defined within the fab.lbr Eagle library.I used an existing 8 pin component as the basis of a new pressure sensor package and symbol and modified it.

Pressure sensor pads were resized and spaced according to its datasheet within the properties menu. Pin 1 was further distinguished with round solder pad corners to aid alignment on the board. Pins were also uniquely labeled and connected.

|

|

I used the Autorouting tool within Eagle to initially populate

most of the traces on the board after restricting the tool to

the top surface of the board for single-sided milling. I

refined the positions of some traces by hand and manually routed

traces the Autorouter was unable to place. To manually

route the missing traces four new 0 Ohm jumpers had to be

included into the Eagle schematic and positioned in the board

view.

As part of Autorouting the traces, I modified the Design Rule

Check (DRC) fields under the Tools tab to increase the

spacing between neighboring traces and pads to 0.016 in

(0.4mm). Despite this adjustment, four solder pads were

left fused together on the milled board when the end mill could

not travel between certain gaps.

Fabrication:

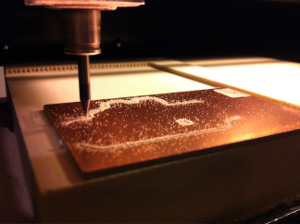

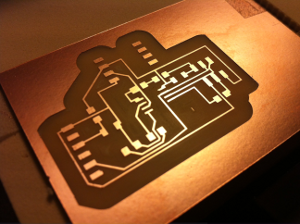

The sensor board was fabricated from high resolution (1200 dpi)

black and white silhouette, PNG formatted images exported from

Eagle using the Roland Modela MDX-20 and Fab Modules. The

separate trace and perimeter files were cut with 1/64 inch

(0.40mm) and 1/32 inch (0.79mm) diameter end mills

respectively.

|

|

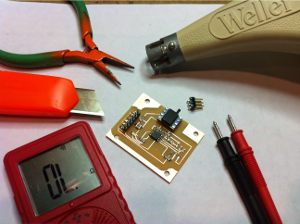

Areas not milled included the traces and neighboring pads of

the ISP 6 pin header. These features were manually

separated by cutting through the copper foil with a utility

knife and checking discontinuity with a multimeter.

Programming:

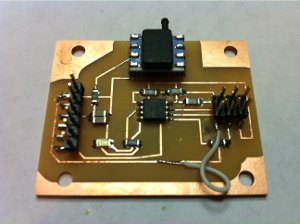

While I identified and separated two of the fused pads prior to

stuffing the board, it was not until I attempted to program it

with the Fab ISP and experienced several initialization

failed errors when attempting to compile the sketch that I

reexamined the board again visually and with a multimeter and

discovered two more fused pads. The ISP header was heated

with a hot air gun and removed to separate the traces beneath

it. A wire jumper was used to bypass the trace torn from

the board while removing the ISP header. Repairs were

checked with a multimeter prior to reprogramming the

board.

|

|

|

|

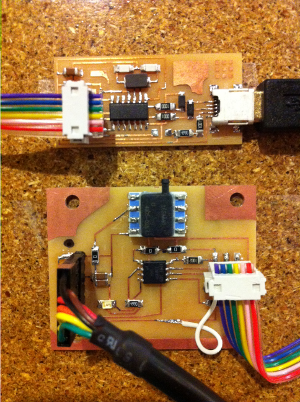

Separating the pads and traces resolved the error issue I

experienced when first attempting to communicate with the sensor

board over the Fab ISP. I used a simple Arduino sketch to

control the ATtiny45 to compare the measured sensor output

against a threshold integer and light a LED depending on the

relationship between the two.

Rather than a steady light from the LED set to HIGH I observed

a irregular flickering which I am troubleshooting.