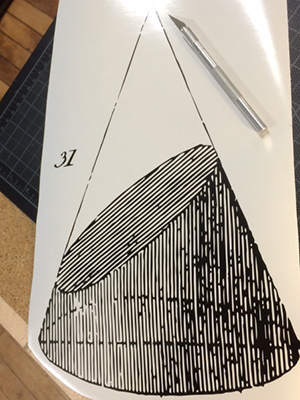

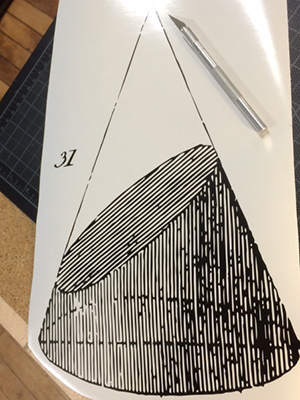

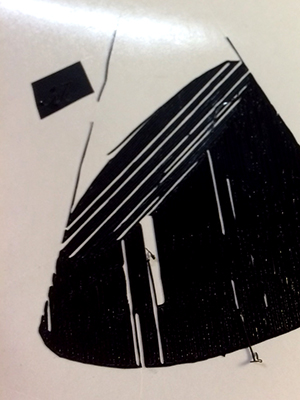

On the vinyl cutter, I worked with a historic engraving that I had of a geometric form. I scanned the image at a high resolution and used Livetrace in Adobe Illustrator to convert the black lines of the engraving into vector artwork. The image held such a high amount of detail that the first one I tried to cut failed miserably. It was far too detailed to be cut that small, so I recut the file to be about 4 times larger and it worked perfectly. The final image took about 40 minutes to weed, but it was incredibly fun.

With the laser cutter, I began experimenting with these wonderful living hinge files that I found online, posted on GitHub by Obrary a startup in San Diego. I made the terrible mistake of attempting to cut it out of cardboard, which made a huge fire almost instantly. I then moved to MDF and it cut perfectly. I loved what the form did when it was pulled into a cylinder shape, but I went in other direction.

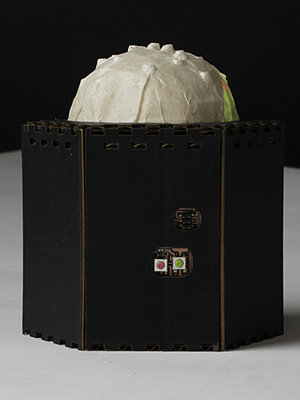

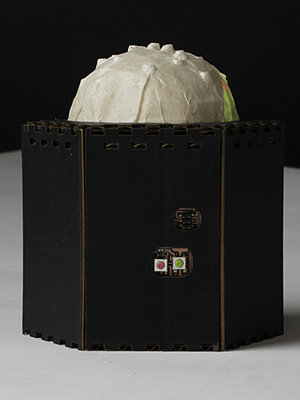

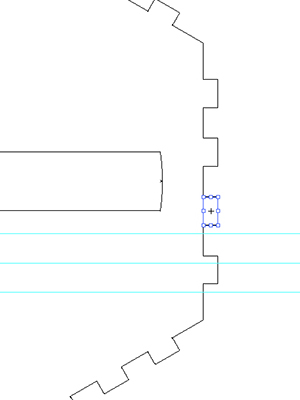

I went back to the drawing board and created a press fit form that was a hexagon. I intentionally made it so that the form was symmetrical so that it could be used in square or triangular shapes. It would just be the top panel that would need to be modified and the same sides could be used. I am very skilled with Illustrator so I wanted to find a way to do parametric design in that program. I ended up watching a tutorial on how to use symbols and that seemed to be the best option. I created a new graphic symbol using center registration and that way I was able to make slight changes to the one master symbol, and it adjusted everything else.

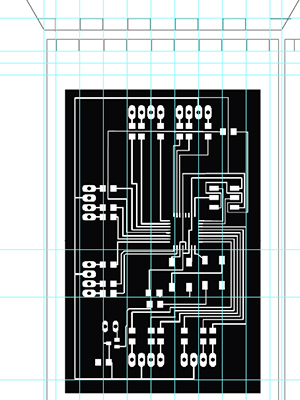

When it came time to place my circuit board into my press fit box, I used the .png file that was created in Eagle and placed it directly into my illustrator file. I was happy to see that it placed at actual size, meaning that I could use that as a reference to cut out where my buttons and programming header were.

Files Press Fit Moon File