APPLICATIONS AND IMPLICATIONS

JILL HARTLEY YOKOTA, AS220 FAB LAB, PROVIDENCE, RI

ASSIGNMENT: Propose a final project that integrates the range of units covered. What will it do? Who's done what beforehand? What materials and components will be required? Where will they come from? How much will it cost? What parts and systems will be made? What processes will be used? What tasks need to be completed? What questions need to be answered? What is the schedule? How will it be evaluated?

WHAT WILL IT DO?

GlowHouse is a prototype for a children's indoor "chillaxing" space that's equal part fort and twin sized bed. When completed, it will have a roof made out of natural HDPE with embedded LEDs that play an animated sequence when a button is pressed. The GlowHouse was made from eco-plywood and can be flat packed for moving and shipping purposes.

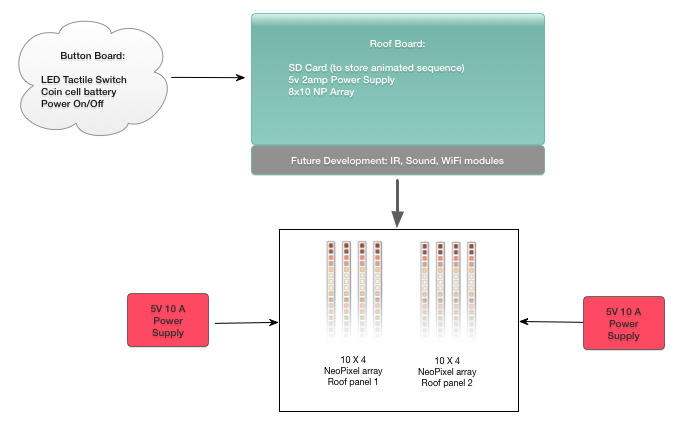

After much paring down, this is the revised project flow chart showing the various electronics components. "Future development" will not be included in the prototype for my final project.

WHO'S DONE WHAT BEFOREHAND?

I haven't (yet) seen a project like mine, though I'm aware that other FabAcademy students have worked with programmable LEDs, like Peter Fearey. My project has been inspired by a couple of sources, including the Umbra Casa tissue box and DucDuc, my favorite children's furniture design company.

Umbra Casa Tissue Box by Mauricio Affonso:

Bed and table designs from DucDuc:

WHAT MATERIALS AND COMPONENTS WILL BE REQUIRED?

GlowHouse will be made from eco-plywood (no formaldehyde) veneered in walnut for the walls and floor and HDPE for the roof panels. It will rest on black concrete and rebar piers that I made during composites week. The full inventory of material and components is not yet complete, but can be downloaded here.

WHERE WILL THEY COME FROM?

The structural materials will be sourced locally in Providence whenever possible and electronics will be sourced from the Providence FabLab, in addition to various online sources including AdaFruit, SparkFun, Amazon and Mouser Electronics. The sourcing of material and components is not yet complete, but can be downloaded here.

HOW MUCH WILL IT COST?

Too much! But, I knew that building a large house-like structure would be expensive. The cost of material and components is not yet complete, but can be downloaded here. Estimated cost ~$2,500.

WHAT PARTS AND SYSTEMS WILL BE MADE?

The house structure (walls, roof panels, floor and concrete piers) were made by me. Additionally the electronics, including button board, roof board and LED wired matrix will be all handmade by me. The programmable LEDs, fasteners, myriad components and power supplies are store bought from various sources.

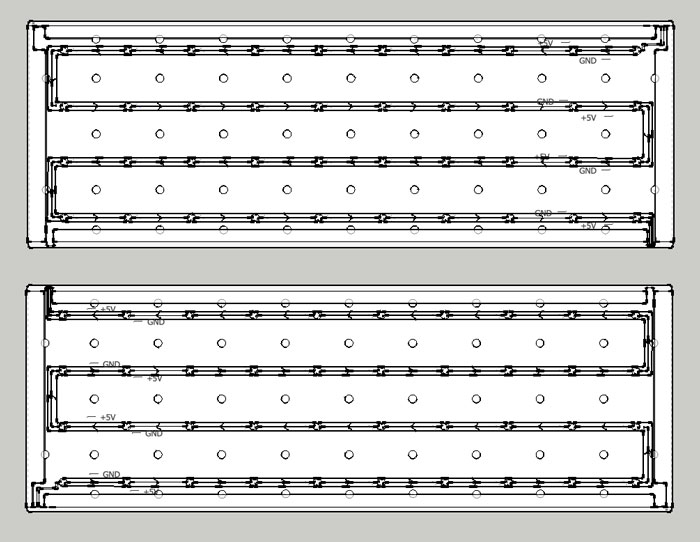

Here is the layout of the LED matrix that will be made by hand and embedded in the roof panels:

WHAT PROCESSES WILL BE USED?

The GlowHouse walls and roof panels were designed in SketchUp and are being cut on the CNC router. The button and roof boards are being designed in Eagle and will be milled on the Modella. The Arduino IDE will be used to test and program the LEDs and Processing examples will be attempted. The button board will communicate with the roof board serially to start and using IR in the future. The membrane of the button board will be another composite made of linen and silicon.

WHAT TASKS NEED TO BE COMPLETED?

Roof Panels:SketchUp models need to be finalized. Cut tests in plywood, fit to roof and test joinery. Adapt and revise design, if needed. Once finalized, cut roof panels in HDPE.

Button Board:Design in Eagle. Mill board, stuff and test. Prototype will probably be serial connection between button board and roof board. IR integration is preferred, but may get bumped to future development. Make silicon and linen membrane.

Roof Board:Finish design in Eagle. This board will have an SD card reader to store the animated sequence(s) and will control the LED matrix. Mill board, stuff and test. Download boot loader, test with Arduino IDE NeoPixel sketches, modify sketches. Test storing animation on SD card and Arduino sketch reading properly.

Light Matrix:Design close to completion. Create small 2x2 matrix for testing purposes. Layout 8x10 LED matrix with appropriate spacing, cut wire segments, wire-up and solder parts, provide power, test. Fixture to HDPE interior. Enclose matrix, mount on roof and test further.

Animated Sequence:Build upon samples and test, test, test.

Presentation:Cable routing and hardware hidden? Power mount on underside, or use laptop locker?

Repair & Finish:Repair veneer splinters, sand and wax wood panels.

Piers:Level using grinder, finish with wax and buff.

Fully Assemble Prototype & Test:Is is sturdy and strong? Does it work? Will any small children be electrocuted?

WHAT QUESTIONS NEED TO BE ANSWERED?

- Animation length and memory requirements?

- Difficulty integrating IR given schedule?

- Ridgeline joint? Fixturing of HDPE along ridgeline? Use spline joint, or will interior L-brackets hold together tightly enough? Test cuts in wood first.

- Roof-to-wall joint? Dowels sufficiently strong? Can it still be disassembled?

- Will insert fasteners become loose with humidity in summer? Do they need to be epoxied into holes?

WHAT IS THE SCHEDULE?

Week of May 18: Cut test roof panels in plywood on CNC, fit and revise design if needed. Cut replacement side panel with accurate dimensions. Route, mill, stuff, test roof board. Cut final roof panels in HDPE. Work on machine building project.

Week of May 25: Work on machine building project. Test joinery of HDPE roof. Create doweled connections between roof and walls. Design, route, mill, stuff, test button board. Create programmable LED matrix, test with Arduino IDE examples and embed in roof.

Week of June 1: Test button board triggering Arduino IDE examples in lights. Try programming additional sequences. Level piers with grinder, wax and fixture to underside of GlowHouse.

Week of June 8: What needs to be done?

Weeks of June 15, 22, 29: Incorporate IR? Make cloud button board enclosure? Finishing work.

HOW WILL IT BE EVALUATED?

Does it work? Can it be expanded upon? It was designed to be assembled and disassembled - how well does it do that? How can it be improved upon, expanded in functionality and fabricated for less cost? The first evaluators will be my kids! They've anxiously awaited completion of this project and are eager to try it out. The next evaluators will be my peers and instructors at FabAcademy. Post-protoype, I would like to have GlowHouse critiqued by DucDuc and other children's furniture designers.