Assignment: redraw the echo hello-world board, add (at least) a button and LED (with current-limiting resistor) check the design rules, and make it

I never designed a board before. An Arduino, breadboard and a sketchpad was the extent of my knowledge in electronics design. As I badly needed an AUX input in my old diesel VW golf, I found a schematic of a module I would simply have to plug in my CD changer port. This was quite exciting but I had to design the PCB from scratch usgin Fritzing. During the weekend, I deicded to try KiCad with the PCB Designer Extension, Eagle and Fritzing. I tried to install Gerber on my linux box without success and as time to complete this assignment was quite short, I could not spend hours figuring out dependencies. I experimented KiCad, drawing a very simple circuit and trying to export is as a SVG to produce a board. If KiCad was very efficient to design, the downfalls were the lack of comprehensive component library and the innability of the software to produce a coherent PCB design file. After about two hours of work, I switched to Eagle. Now Eagle is a very powerful EDS but the learning curve ended being too much for me. It is much more like a CAD software than what I expected. I will definitly give it an other try when time permit and I can truly spend hours

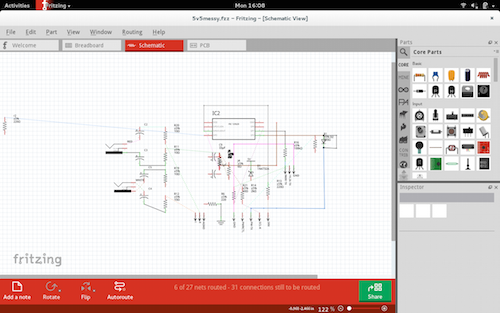

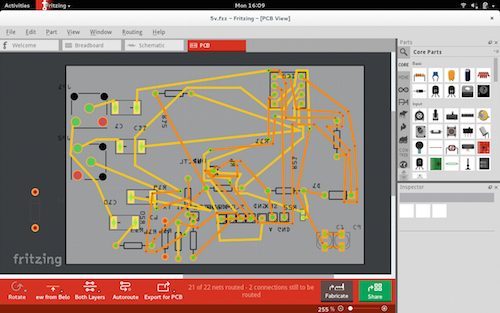

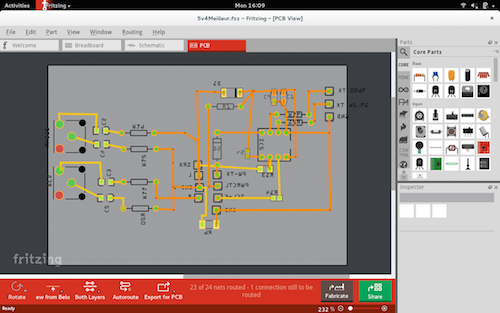

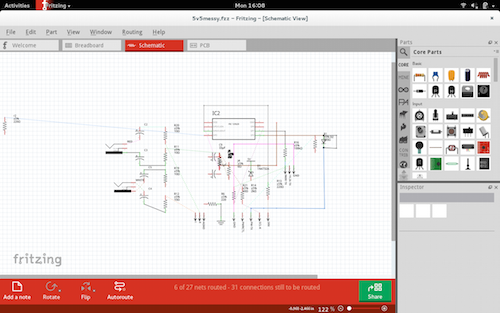

Armed with my electronic book and the original schematic, I used the Schematic view in Fritzing to reproduce the schematic. Upon switching to the PCB view I admired a complete mess of connexions. Pretty much all of them unrelated to my schematic. So using simple logic and some patience, I redesigned all connexions to my components, making sure the path make sense in real world. Fritzing is a quite simple software. I decided against using the parts library as is but instead, using generic components (SMD) and modifying tags and specs. Exporting files to the CNC is a breeze. It produce either PNG files or GRB files with drill patterns. As it sometime crashes on my Linux box, I would recommend saving as often as creating a new component or connexion.

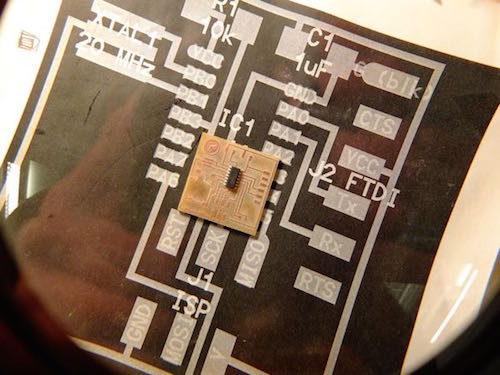

I teamed up with Raphaël to increase the speed of the workflow in order to produce my hello board in time for this week assignment. The board was redrawn in Eagle and processed in Aspire to produce the appropriate GCODE. We milled the board on our SFF CNC, a job of about 45 minute. The neat thing about SMD is that there is no drill file hence it's much quicker to produce. After soldering the FabISP module, I fear not surface mount components anymore. The soldering process took under 30 minutes with the most important factor being strong lighting in order to see the parts adequately. Using my FabISP module, I was able to test the hello board. Pressing the button activate the red LED. Yeah!

I'm still in the process of manufacturing my CDchangerAUX module. If I have time in the next few weeks, I should update this page