Assignment: design and 3D print an object (small, few cm) that could not be made subtractively and 3D scan an object

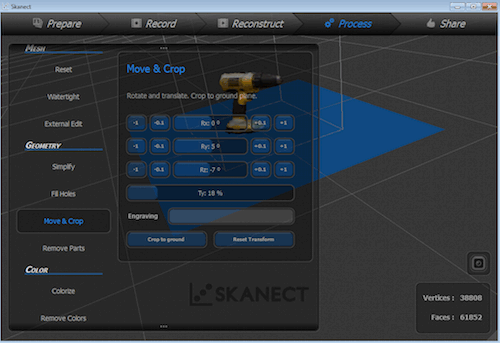

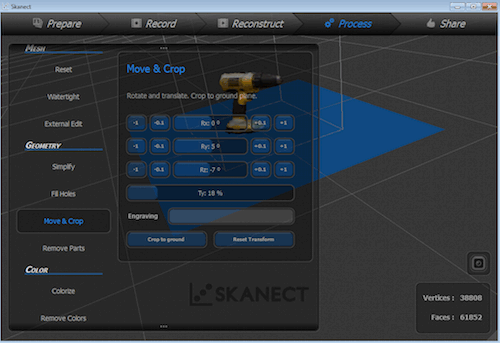

This week assignment was took me much longer than I could imagine. We do not have a 3D scanner on hand hence we generaly use a Kinect with Skanect as the driving software. We successfuly used that workflow to scan full size body using a contraption of our design. It was my first time using the same process to scan a small object. The fisrt thing I tried to scan was a lemon. After some trial and errors (many) I was able to get something that did look like a 3D lemon. The problem was that the lemon reflect too much light due to is glossy apprearance. Trying to scan a DeWalt drill was much easier, using the same settings. I was able to define a bounding box small enough to encompass only the drill and noting else. The result was exported to meshlab and repaired using the default settings. I was then able to make a perfectly watertight model of my drill that would be printable.

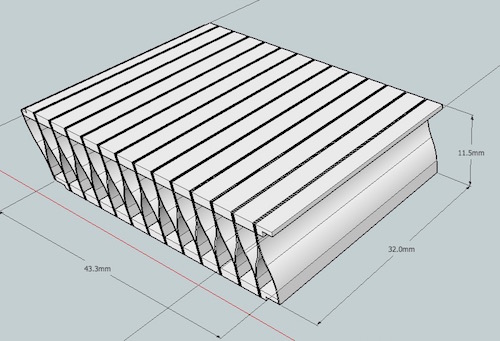

I was inspired by a model I've seen on the architecture section of Sketchup 3D Warehouse some months ago. The model, is in my opinion impossible to manufacture substractively because of the deepness of the grooves and very fine detailling. I was not able to find the model again so I produced it from memory and a screenshot I had saved. It's composed of a straight header and footer with very fine curvy branches.

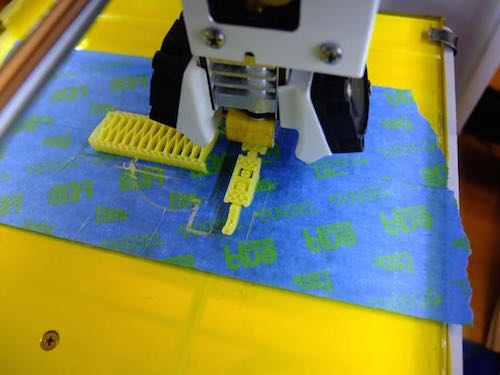

Using Cura and a Ditto Pro 3D Printer : Raphaël and I used Cura to prepare a plate with our objects on it. It's a very easy process. Simply drag and drop the .obj or .stl files in the main window, placing them properly and prepare the print on a SD card. The printer is as userfriendly as a microwave oven. I selected the .gcode file and pressed print. An hour later, our two files were ready. The only problem I faced was that my first attempt use walls of 0.9mm which were way too big conidering my design. I had to stop the print and start it again with 0.3mm walls. This could have been prevented if I had checked the layer view in Cura, used to preview each and every slice of a model to be printed.

[-Blank space for future updates-]