Assignment: design, make, and document a press-fit construction kit.

After this week lecture, I had many ideas to explore. I was quite impress with Neal's proposed usage of the vinyl cutter, a tool I never used before. So I'm loggin all my attempts, faillure and some success. My first idea was to create a lamp using an Ikea socket, fluorescent lightbulb and laser cutted outter shell of the Fab House. Unfortunately, I'm not talented enough using sketchup to redesign the shell and the files available on FabLabBCN wiki are unavailable. I will report that project to a later day as I'm still willing to try it.

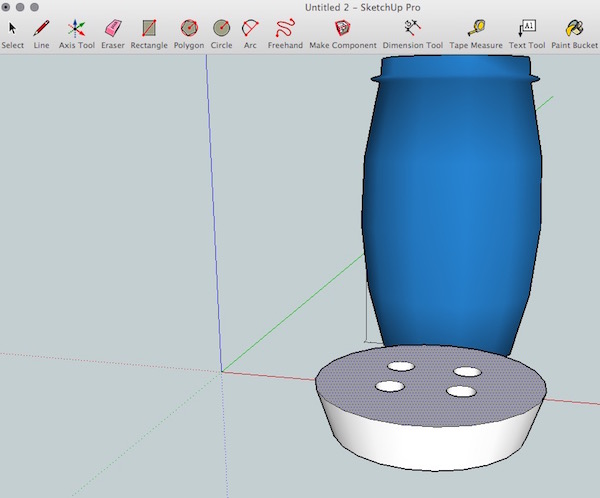

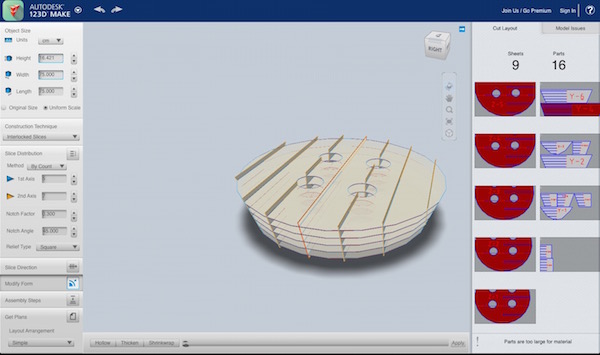

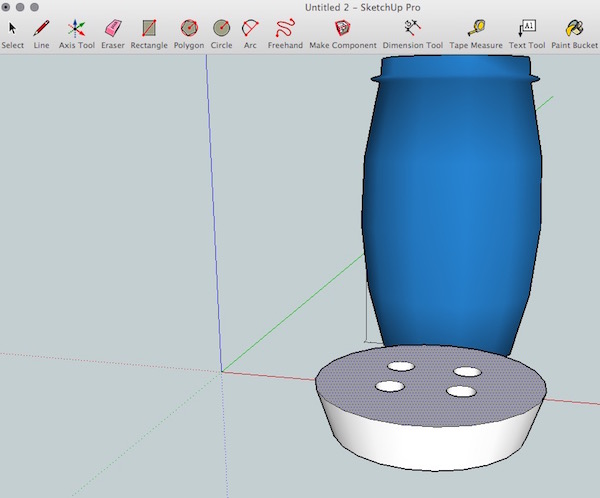

Ok, it looks like a giant cup holder you'd get at Tim Hortons but it's not. This contraption is a kit cut of a hydroponic cupboard that would fit in the barrel for my final project. The idea is to later cut it in food grade HDPE and use it as the support for the tomato plants. I used SketchUp as a design tool to make the form, and holes for the cups. I plan to use OpenSCAD to make a parametric version of this so it will be adaptable to any plastic drum barrel. I then used Autodesk 123D-Make to prepare the slices. Playing around with the settings, I tried as many options I could until satisfied by the result. Now it's only when I assembled the first prototype that I realized that usign radial slices instead of interlocked slices, for a model that is round with holes in it, was a bad idea. It's almost impossible to fit the inner parts correctly, without folding the cardboard. The overall process was acceptable but definitely not optimal.

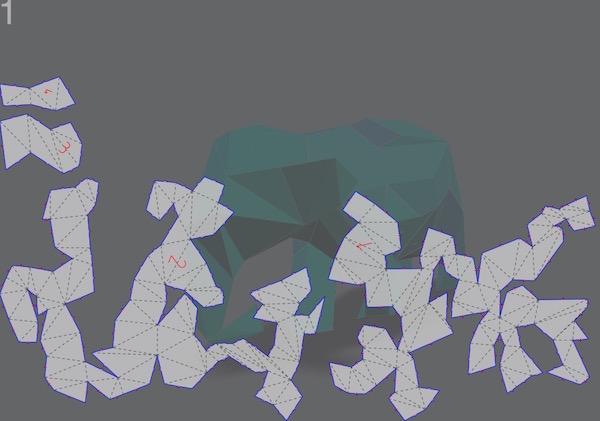

Having played with multiple options in 123DMake, I wanted to explore the folded pannel constuction method. I used an elephant STL file found on Thingiverse (thing:38573) as a model in 123D. I selected Folded Pannel as a construction method. As we use a Trotec speedy 300 laser cutter here, I created a new color (green) to act as folding lines. This setting would allow the machine to cut through the first layers of cardboard but not the last one, allowing me to fold my elephant following the pattern. I selected a 1.5mil corrugated cardboard, the thinest available here. After 5 minutes of lasering, I was quite happy with the look of it. Trying to fold it was a major fail. The cardboard fiber were too strong to keep their fold. The folding almost impossible in certain angles. I have to try it again with thinner non-corrugated cardboard. Maybe next week.

Inspired the natural existence of notch in nature, I decided to create a sculpture using the shape of a poppy flower. This design is well adapted to material varying in thickness. This sculplture is composed of 54 poppy flowers. Designed in Illustrator, I imported the file in Inkscape to prepare the cut on the Trotec. Using 2mm corrugated cardboard, I filled the cutting surface and lauchend the job. Been all identical and having grooves allowing for material compression, the fit quite well. It's possible to assemble them in a box shape and use that structure as a basis for growing the sculpture verticaly. Now if it was not of the meter of snow covering the landscape, I would be looking for similar leafs that could be used for generating parametric shapes easy to assemble.

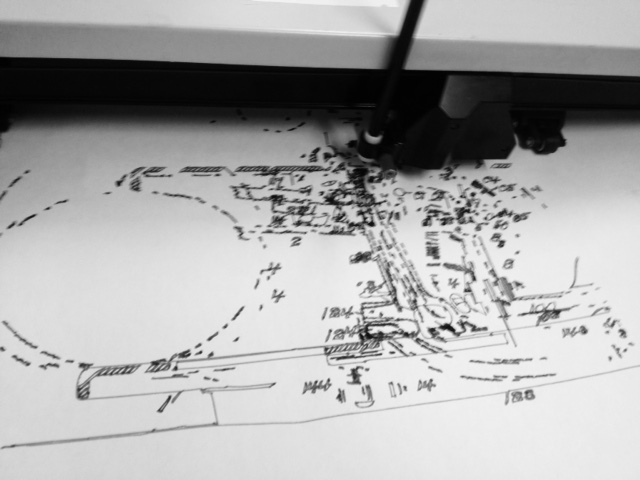

As I said, I never used the plotter before. Sure I used similar machines (Phlatprinter) but never our old and dear (and noisy) Roland CAMM-1. Raphaël and Roby do use it quite frequently to cut and draw and after this week lecture I was set to at least try it. I think that printing flexible circuit is a very neat use of that machine and I would consider using it for that purpose in the future. My goal was to use an exploded view schematic of a typewriter, convert it in paths in Inkscapte, save it in HPGL to send it via the terminal to our machine. The result is quite nice. In the future, I will try to used different pens to obtain a better finish. We 3d printed a fitting colet in order to replace the cutting blade with an hexagonal pen in the plotter. Overall this is pretty easy setup.

This week assignment was pretty much all new to me. I enjoyed using vectorial design software to make the poppies and converting an image to vectors. 123D Make is a very efficient software when it comes to kit making and I will continue to explore the software and other techniques. Unfortunately, it crash every now and then. I will definitely try other cutting techniques to complete my final project and I hope I can obtain better results in the future.