The fourth lesson began with the revision of the press fit for the previous week . At 4.30 pm Neil started to explain the arguments of the week with all the informations on the Electronics Production .

page.

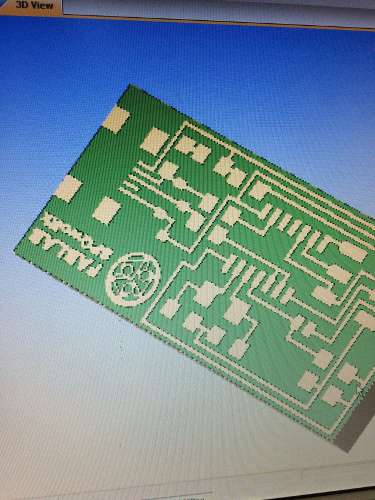

For this module are suggested some materials, but mostly kind of machines. In our fablab we decided to use a milling machine for cut milling circuits on rigid bases FR1 .

The most of Fablab decided to use a Roland machines for this type of work , and using for the software cad cam the Fab moduls.

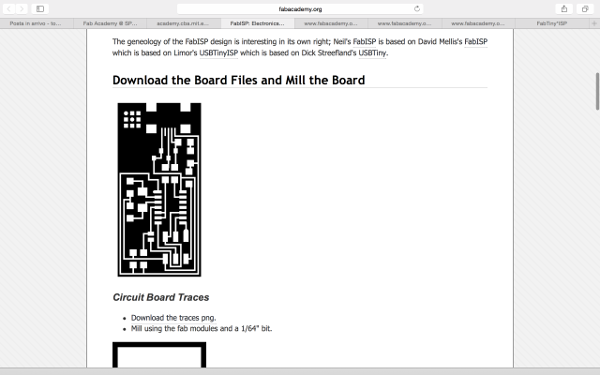

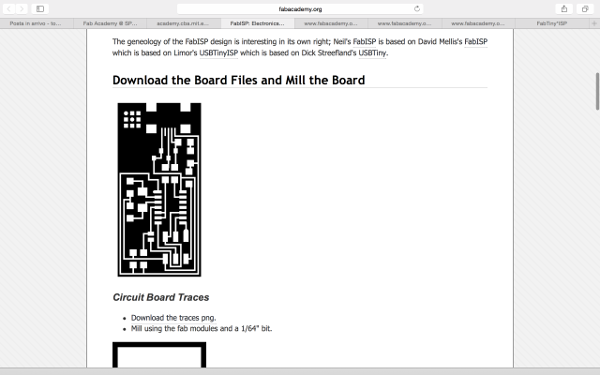

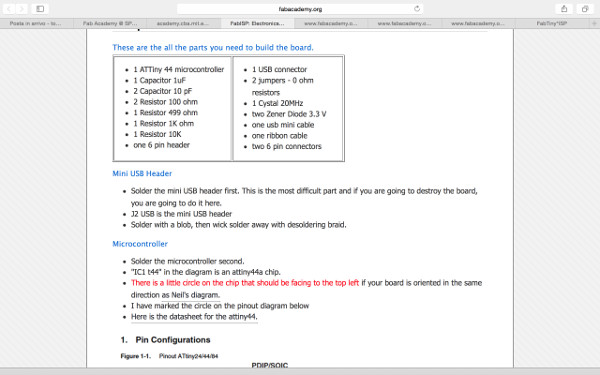

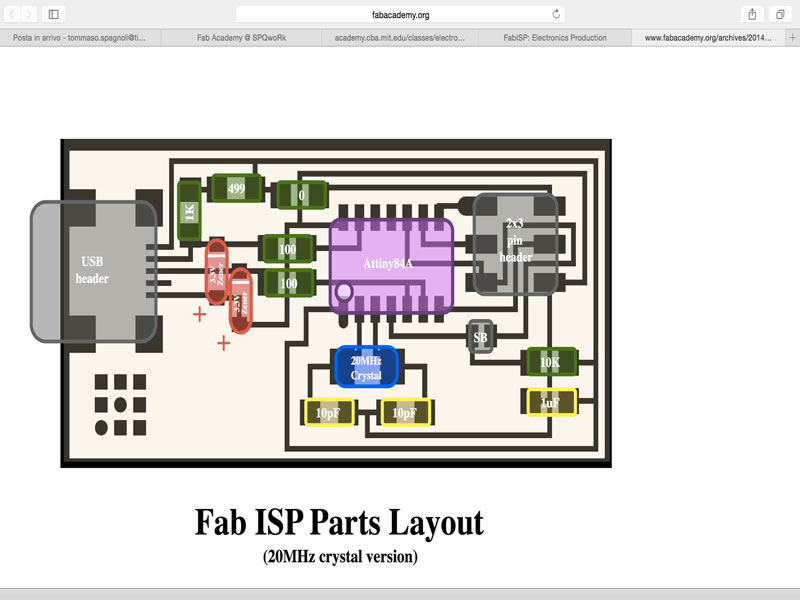

Make the FabISP in-circuit programmer.

The Assignment of this week involves the construction of a FabISP programmer.

For this test we had to make: the customization of the file, the use of the software CAD machine, the milling phase, and the welding of all electrical components. I am very enthusiastic for this assignment because the electronic matter is for me a new field never explored before. After welding the components the card will be connected to the PC to know it works or dosen’t work.

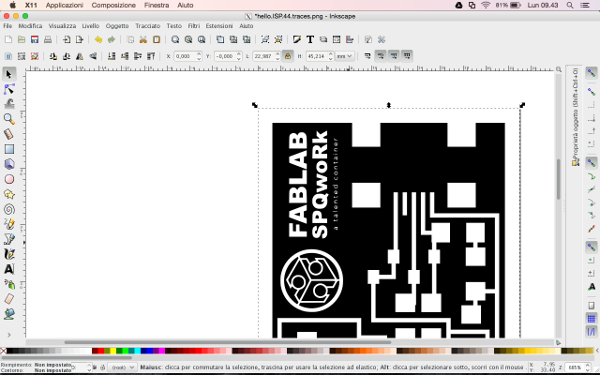

Exercise n1: Customize your FabISP

For this assignment, we used this page as a guide.

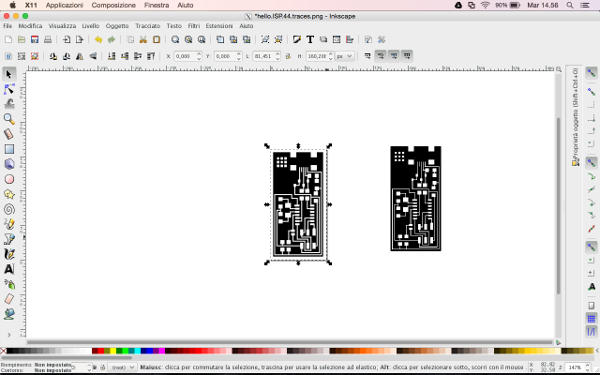

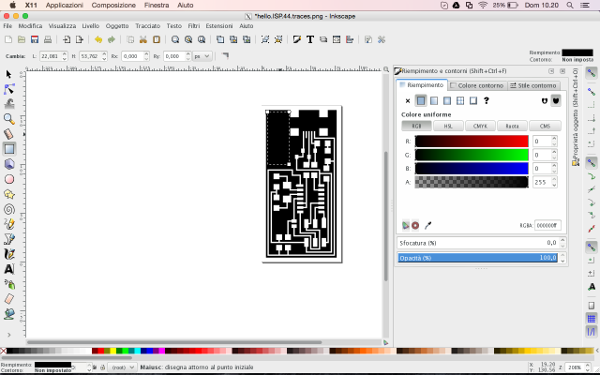

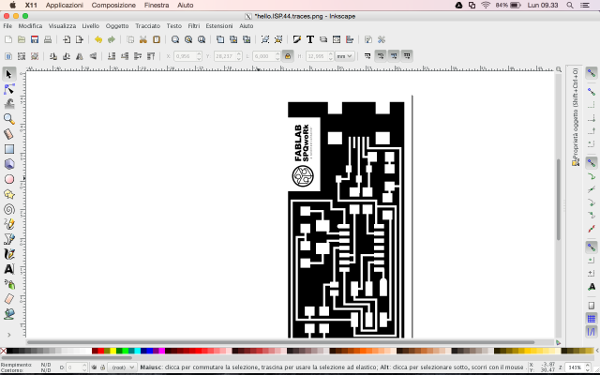

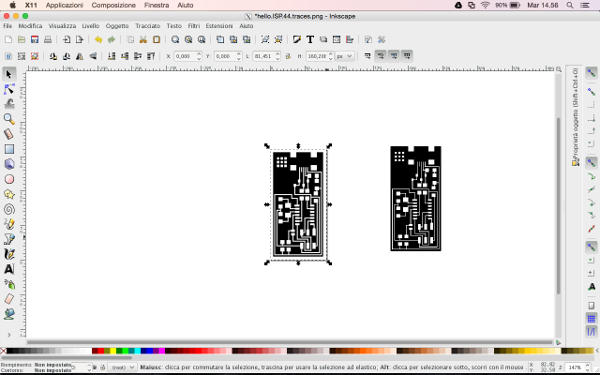

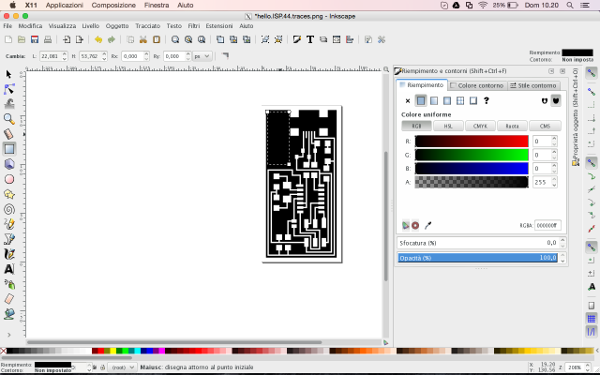

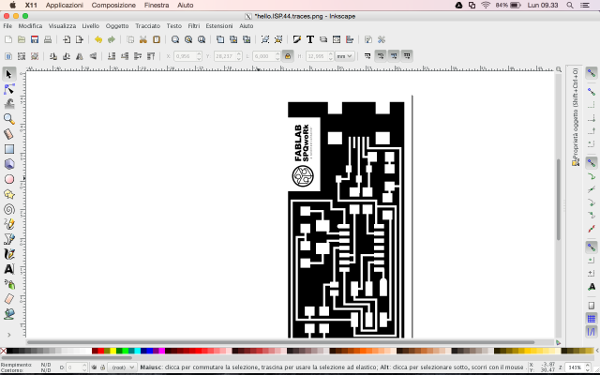

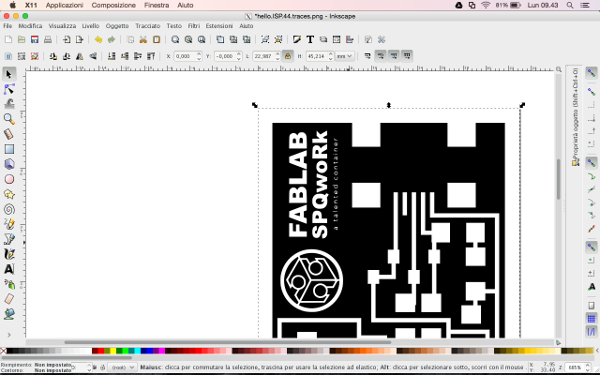

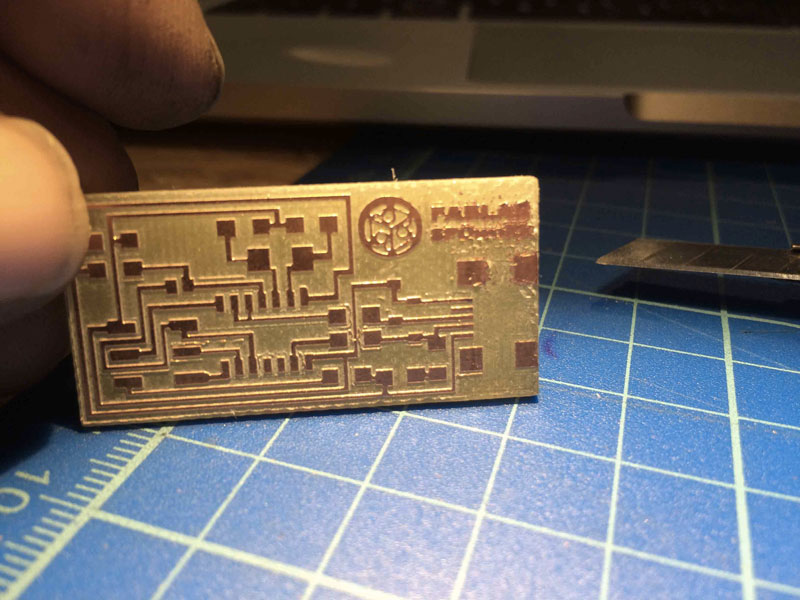

After downloaded the designI opened the file with Inkspape, then I imported an image, that I have cut with Gimp before, and then modified it permanently with Inkscape. When I exported the dvx on the milling machine, the software didn’t read the tracks, so I decided to open the project with Apsire and I remade the tracks.

Exercise n2: Milling the FabISP

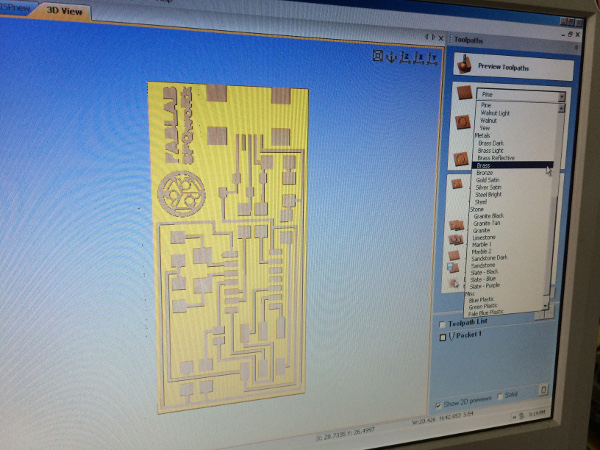

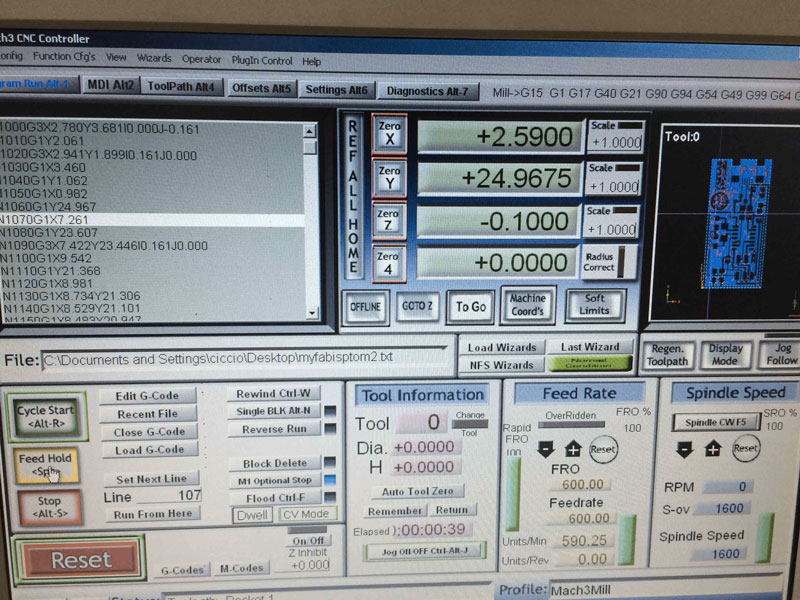

After customizing the design of FabISP, I downloaded the file on the PC control the milling machine. We were using a chinese milling machine model 3040t-dj2, and we were using Aspire CAD program, for the axes xyz control we were using Mach3.

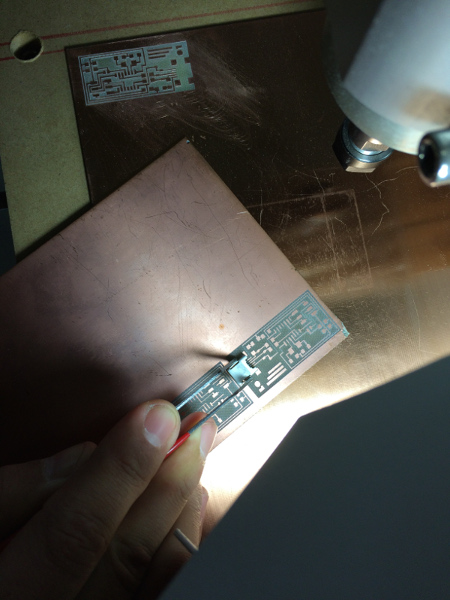

The first milled cards weren't very clean, with to much dirty in the tracks, so we tried many times to have good results.

I didn’t have particular difficulties for this assignment, primarily thanks for the skills present in The Fablab SPQwoRk, a specially thanks to my friend Sergio Subrizi.

About the tips we used: to mill we used a tool 0.25 sharp and with an angle V of 20 °, to cut we used a tip flet end mill 1.5 mm.

As soon as possible we share the advices to use a milling machine like the our milling machine.

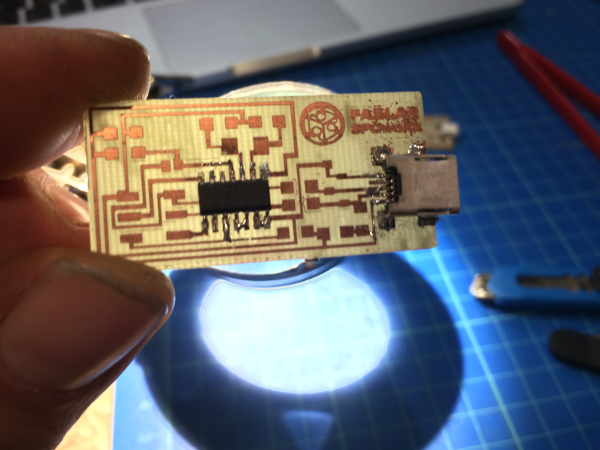

Exercise n3: Soldering FabISP

The welding was my preferite exercise. At the begin I didn’t become curious about the welding, then, after the the third card, I started to like it. I must admit that it wasn’t very difficult, just is necessary a lot of patience and precision, and then I used a digital multimeter, just to checking the presence of a shorts. This check allowed me to understand how the elements must be welded, as the tin solder is necessary and what kind of tips is better to use.

Dowload file Fab ISP layout

Dowload file hello ISP 44

Dowload file hello ISP 44 interior

Dowload file hello ISP 44 traces

Dowload file My Fab ISP

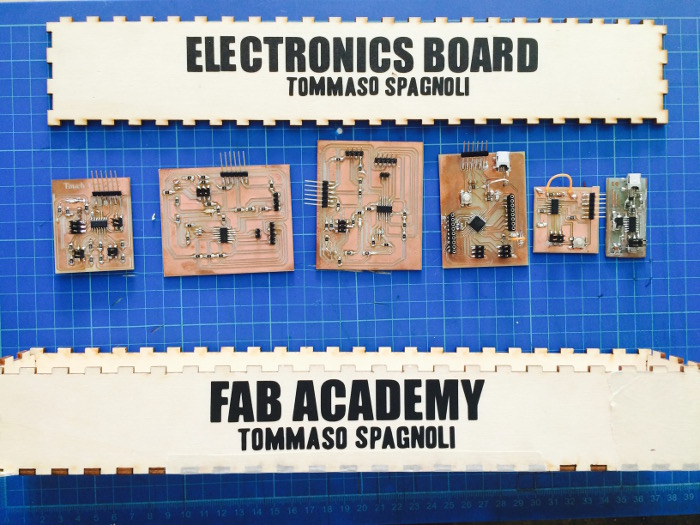

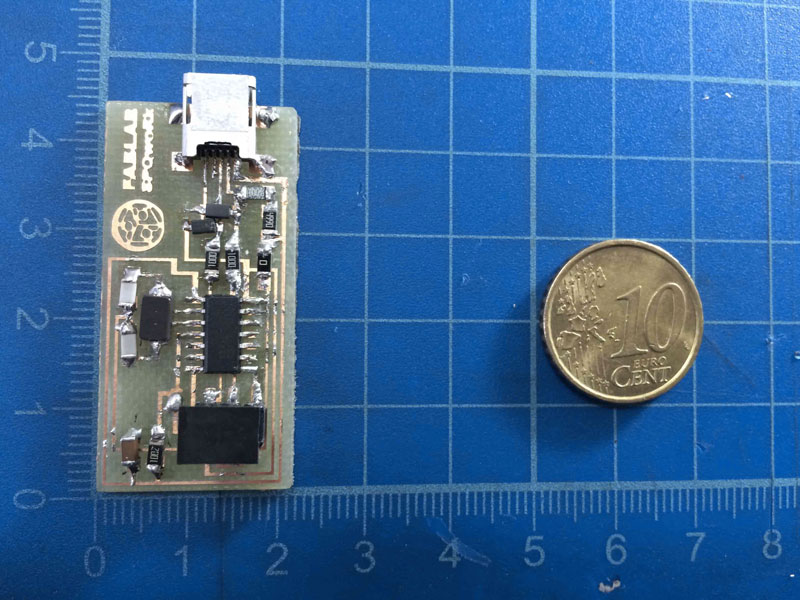

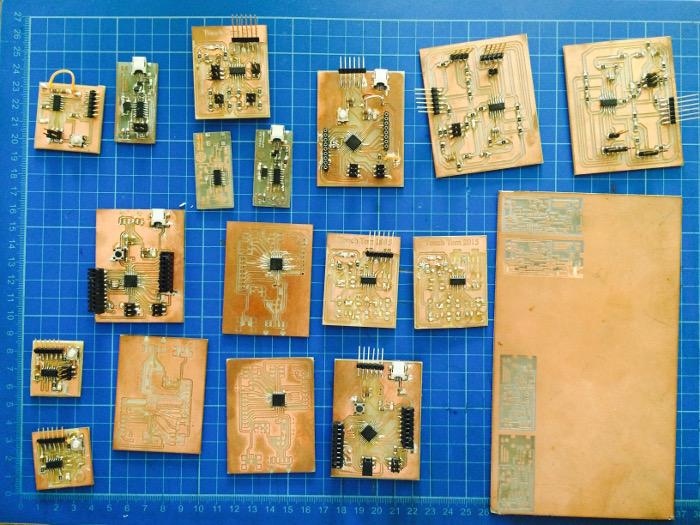

This is "My electronics graveyard"

This is my box where I contain all cards that work well! files for the box and the stickers are in the second part of this web site.