design and make a 3D mold (~ft2), and produce a fiber composite part in it

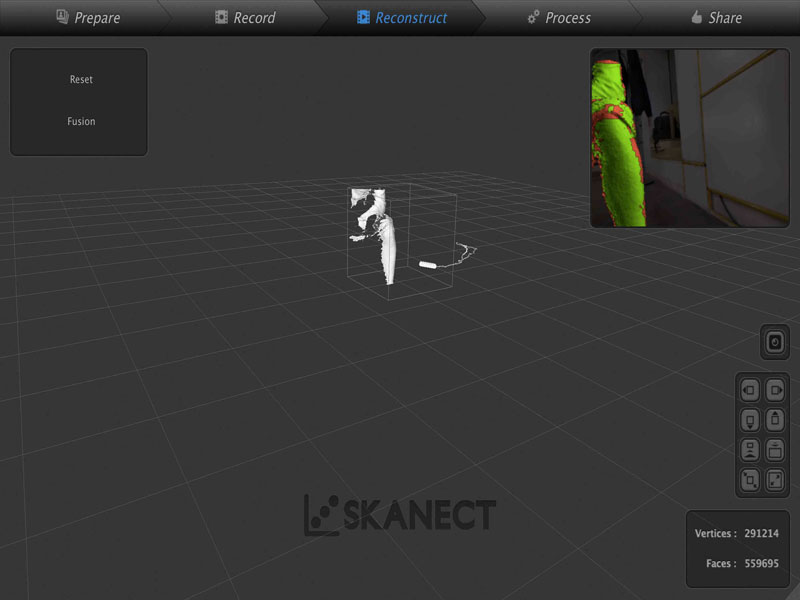

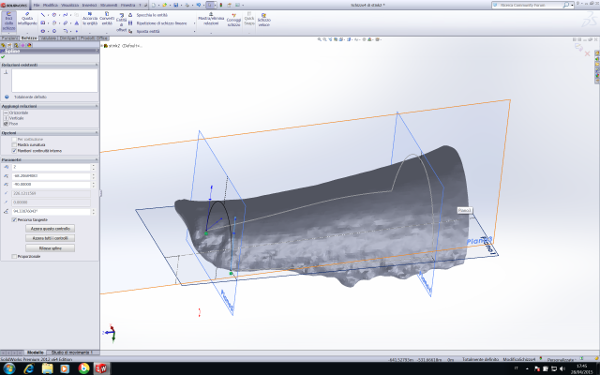

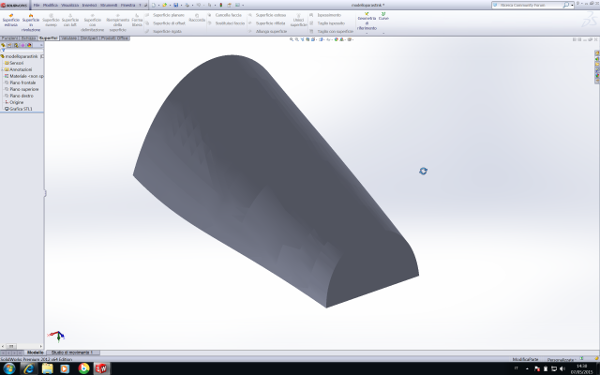

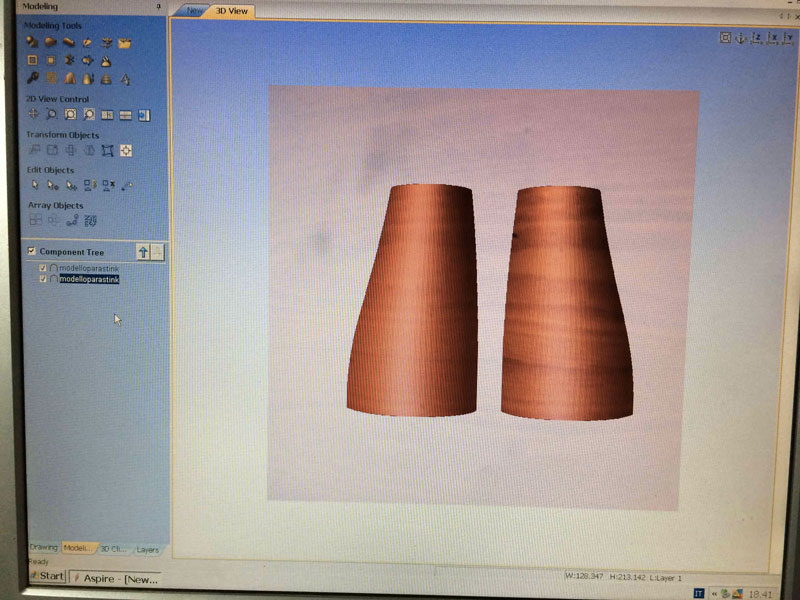

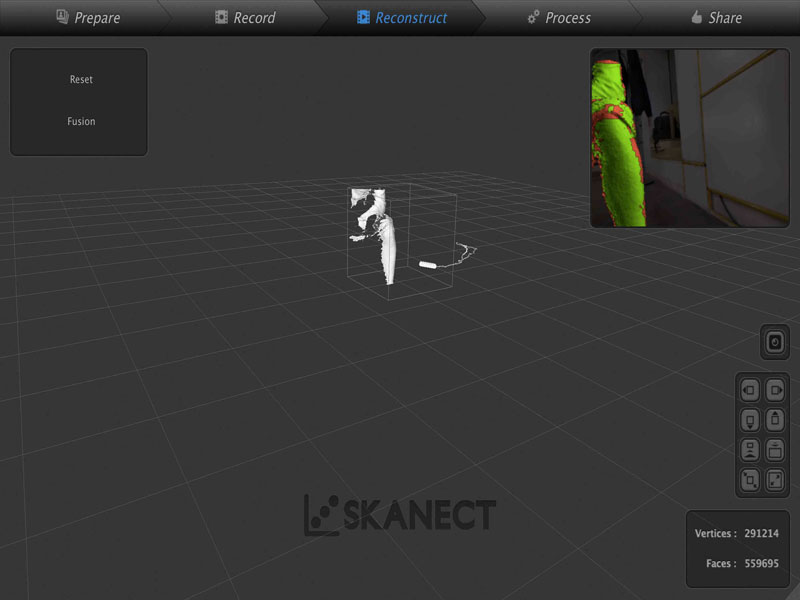

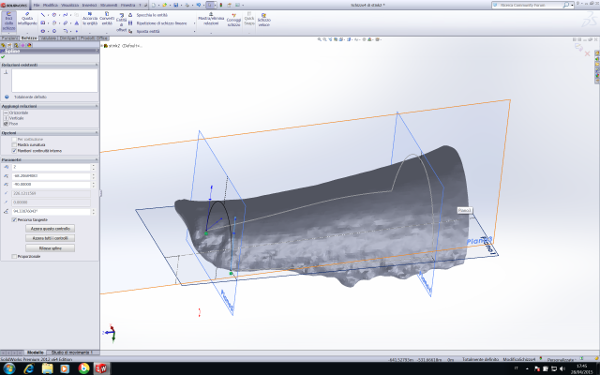

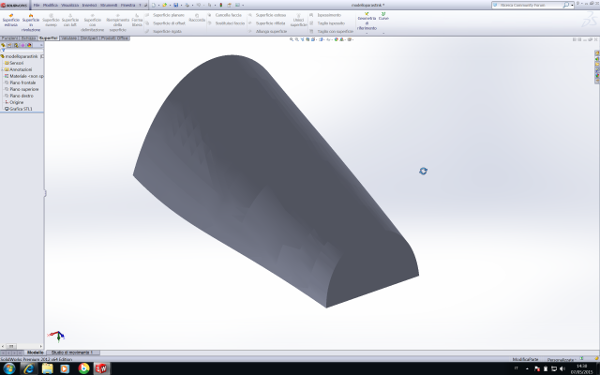

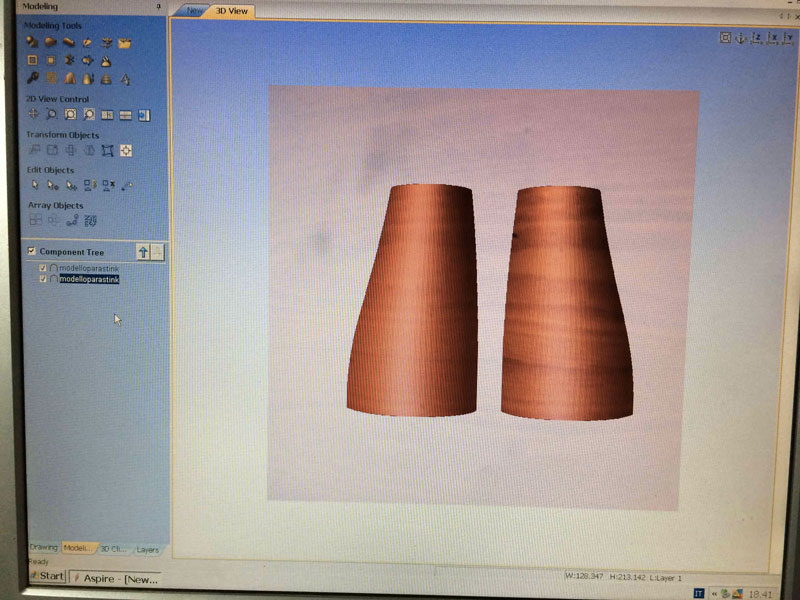

This module is extremely interesting, to make the assignment to the best we have involved a grand master and inventor, Marco Tonci who guided us in the creation of composites. The hardest part is the beginning, where you do the brainstorming about what we can make, in this case we thought of everything from boats to skateboarding, fishing poles, chairs, cases etc etc ... but the temp is just so you have think of something to measure it can be accomplished in a few days and that it is useful to the final project or the life of every day. In my country of origin any given sunday i play soccer, whit my team. When I play football use of shin guards to protect the leg and to strengthen the leg in view of contrasts game. The shinguards common are very uncomfortable because the calf must be tied back with a strap or with a snare. During the match the snare of the shin is very annoying and often comes undone and slides toward the ankle creating problems nell'atleticità movements. So I decided to create this form of shin pads tailored to me! Through the use of Kinect and software Skanect I had a scan of my leg, so I brought the OBJ file of Solid Works and took references scanning intersecting planes of work between them, and closing with the lines points my interest, came out a good job! After scoring the scan and design, I have prepared the file for fesatura with Aspire, the same software I mirrored the pattern, so that you have both the right and the left leg. For cutting I used two polyurethane sheets joined together with the double coated tape, work in the car was very quick, lasted about 10 minutes. The composites is 4 layers, 3 of glass fiber and 1 cloth (do not matter to the imagination flowered). I first prepared a mixture of PVA glue and insulating to pass on the prototype, after rapid drying is applied to the spray insulation, other drying for 10 minutes and another spray for another 10 minutes. This treatment is essential before going and resin composite, because it allows us to isolate the surface and to easily detach the composite prototype. The resin is thoroughly mixed in exact proportions and in a very accurate way, in my case I used 50g of resin and 30g of diluent, mix for 5 minutes and apply with a brush on the first layer of glass fiber, when the liquid is applied then goes distributed throughout the prototype with great care, using rollers, make sure that all parts dellla fibers are soaked and well applied on the surface of the prototype. During these operations strictly wear: rubber gloves, goggles and mask !!!