WEEK 12

12. Composites

While I was thinking at what I could do for this week assignement, I thought that a replica of an architectural structure of a famous building could be the coolest thing to make for an architect like me.

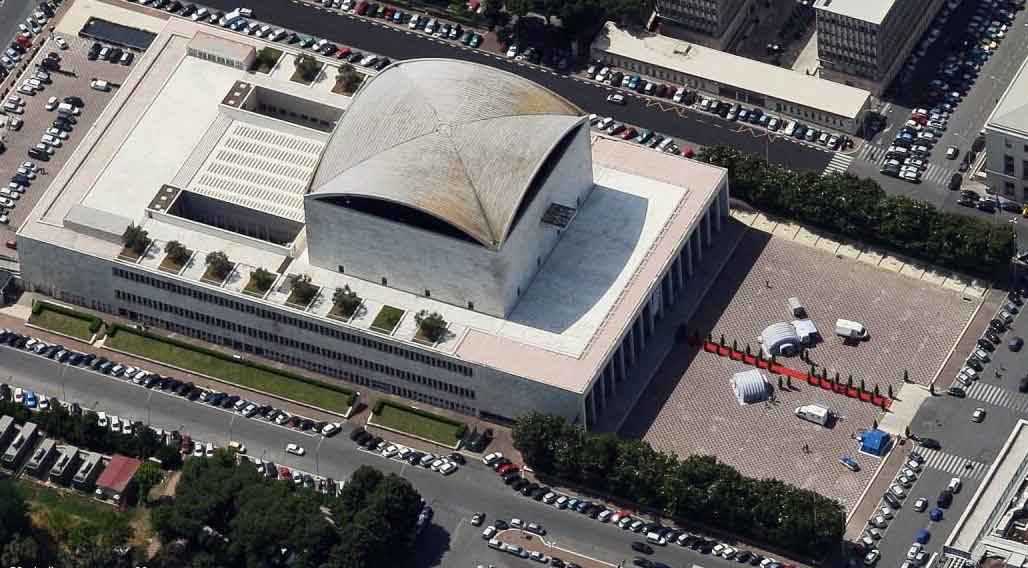

I decided to make the vault of a very important building of Rome's 1942 Universal Exposition. It is called Palazzo dei Congressi and it was designed by one of the most important architect of the rationalist movement, Adalberto Libera.

This building was also the location for 2013's first European Maker Faire.

3D Modeling

I did all the modeling with Sketch Up and then moved to rhinoceros for the mesh and stl definition.

Milling

As a material we used Polyurethane insulation foam panels. These panels comes with a paper/aluminum sheet glued to both sides. I removed the paper on the top side and then attached the panel to the Shopbot using pieces of wood with bolts to clamp the panel firmly.

I started with a roughcut with the biggest tip (1/2") at a spedd of 8"/sec, using "Z level" method. The polyurethane cuts like air and it took only 20 minutes. Then I did a finishing cut with the 3mm ball nose tip at 4"/sec speed, with two passes along x and y axis.

Composite materials test

I wanted to test the epoxy resin as I never used it, so I used some materials I had in the shop:

Resin application

I prepared the mold first by painting it with white paint to achieve a smoother finish and after a day I applyed a layer of release wax which i left overnight for setting (during demolding the paint separated from the polyurethane and stayed on the mold, it was not sticky but I had to scratch it to remove it). I also prepared the fabric, a rough linen, cutting it the size of the mold (with a pair of cm for tolerance) so it would fit perfectly inside the two shells.

I applied Super Sap Epoxy (2 parts resin to 1 part hardener) with a brush making a stamping action instead of brushing. After a first layer of resin, I applied the first square of fabric, then I soaked it with resin and applied a second layer of fabric and epoxy. Then I used the metal roll to make all the air bubble go out.

I then closed the mold and pressed it, Some resin came out, meaning it was well compressed. I clamped everything and let it cure overnight.

Demolding

At demolding, it soon became clear that something went wrong: the layer of paint that was on the polyurethane made a better bond with the wax than with the polyurethane and even if it didn't stick to the resin, the bond to the wax was still strong enough to separate it from the polyurethane. I had to crush the mold which went into pieces and scratch manually the paint from the composite piece.

Nevertheless the piece came out very well, I only had to trim half a centimeter arounf the perimeter, and the overall shape is perfect. It is strong for being only two layers of fabric, so I call it a success. It surely need further cleaning from the white paint.

Files available here