Week 16

Machine Design

MECHANICAL DESIGN, MACHINE DESIGN

GROUP ASSIGNMENT:

make a machine, including the end effector

build the passive parts and operate it manually

document the group project and your individual contribution

This week our assigment was to built a machine starting from a basic kit.

Machines/Science

The kit, consisting of:

- 4 stages = stepper + rod bar

- 8 guide bars

- 4 gestalt circuit boards

- misc materials as nylon bearings

- RS485 connecting cable

- 4 resistor

- plugs

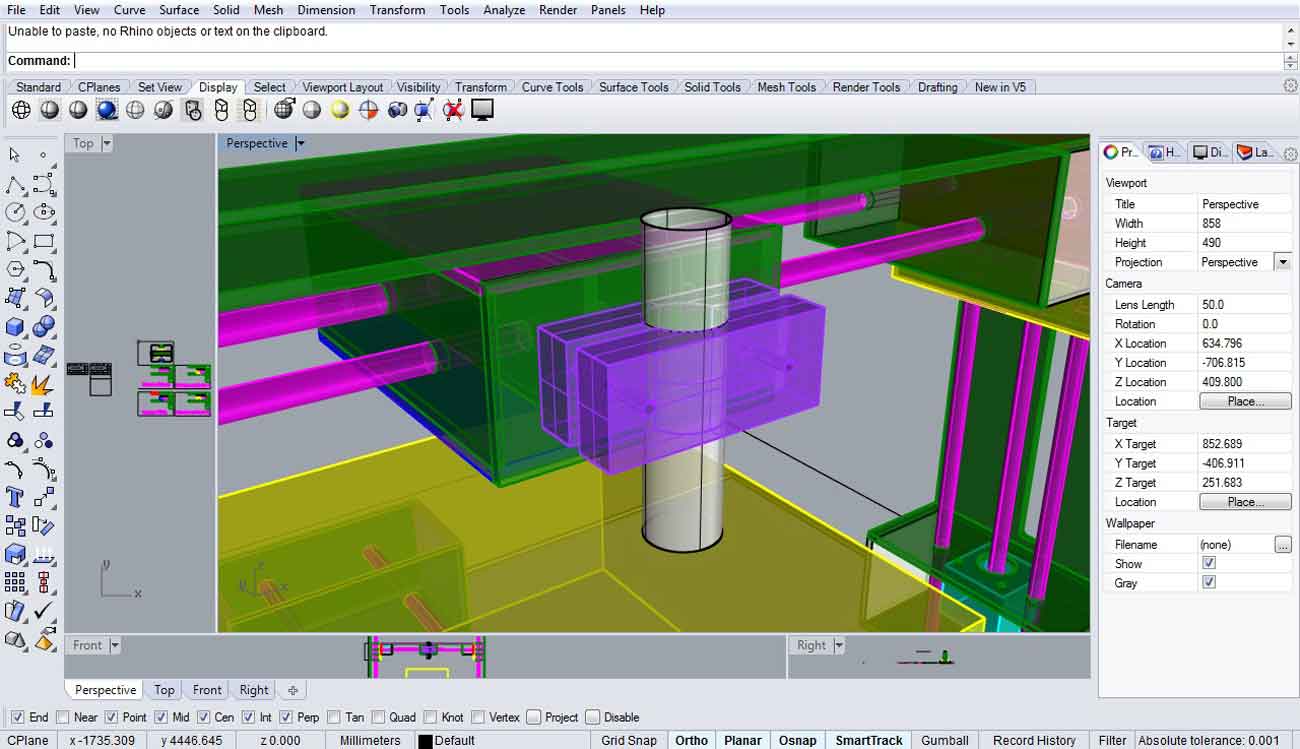

We decided to make a 4-axis machine, using as tools a polystyrene cutter.

To build the structure we decided to follow the tutorial of Nadya, making small changes.

The phases:

1st - Programming

2nd - Graphical interface

3rd - Codification of coordinates

4th - 3D Modeling

5th - 2D drawing elements to cut

6th - Laser cutting

7th - Assembling

We divided tasks according to our cultural background.

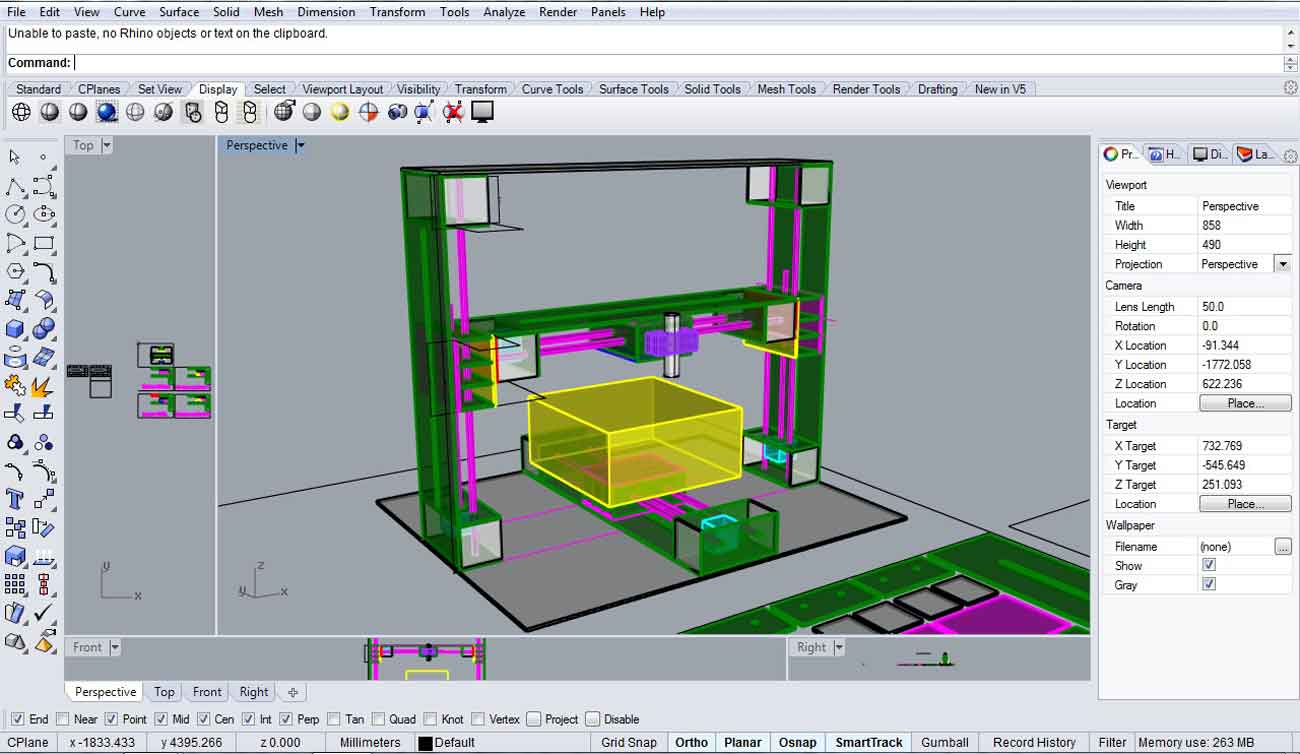

My task was 3D modeling together with Antonio Burrai

After processing the structure, I proceeded to create a press fit of the components, redesigning all the joints of the single components. Then I exported drawings in DXF.

Software used: Rhinoceros.

Antonio and I have modeled together the machine frame, The frame would have to be cut with laser, but, due to technical difficulties, we decided not to do so.

We used the kit that you have provided.

Afterwards, I helped to cut the pieces and to assemble the machine. Programming and realizing of the graphical interface were too complicate for me.

I thank the whole team, but especially Massimiliano Dibitonto, and his tremendous work which allowed the machine to run.

Download:

machine_9.3dmpantograph.dxf

pantograph1.dxf

hot end