16_MECHANICAL DESIGN, MACHINE DESIGN

josefinaPETRINI

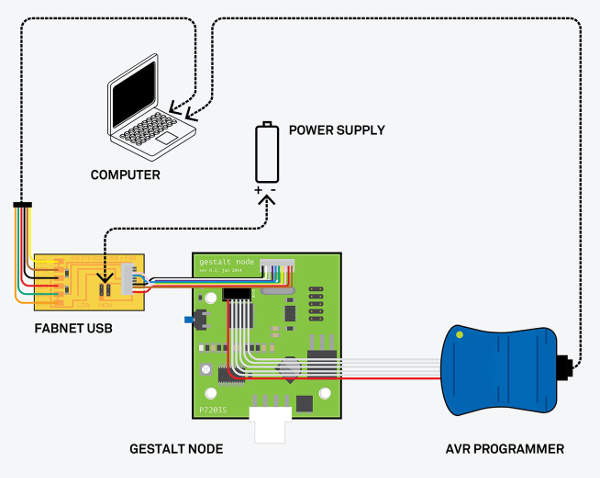

This week was a group assignament, build modular machine parts including an end effector and program it. We started by ordering Cardboard CNC modular machines with its gestalt nodes from Nadya and watching some examples, but the scale of the modules were too short for our idea.

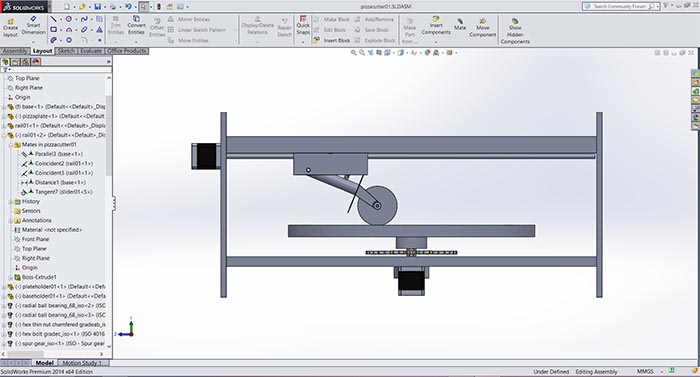

This a pizza cutter machine, which involves a linear and a rotational process.

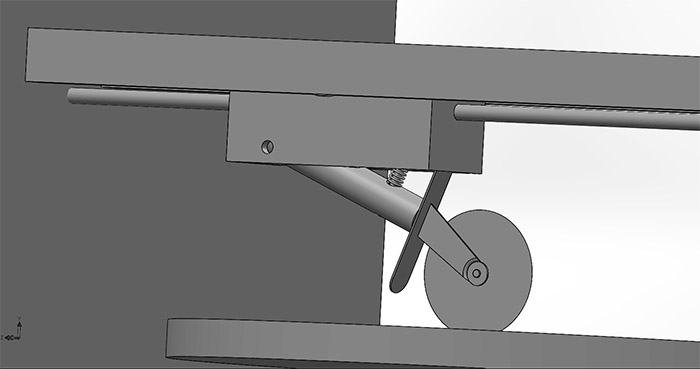

The rotational mechanism consists in:

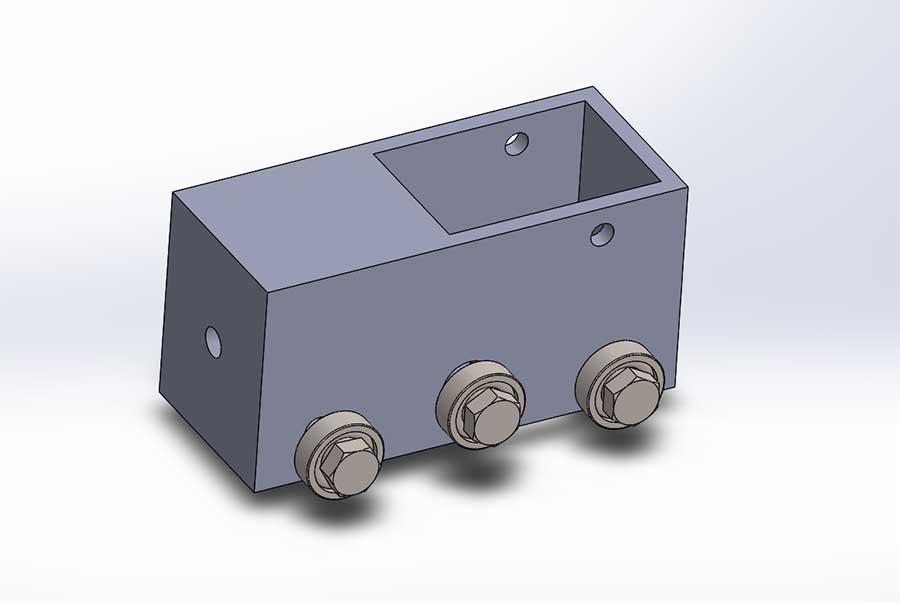

The linear axis instead works equal to the cardboard stages but it is 60cm long, so it will need

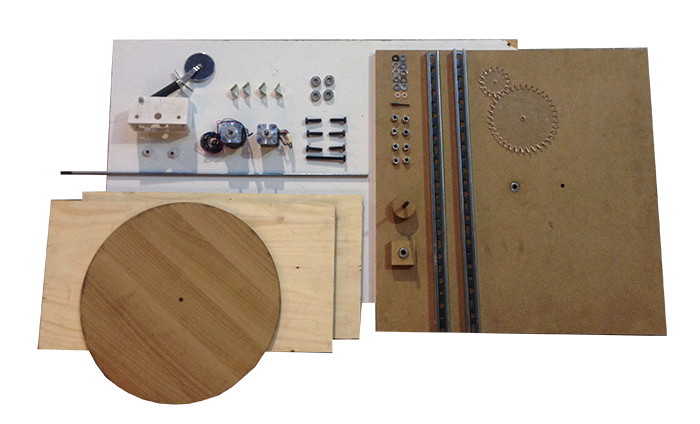

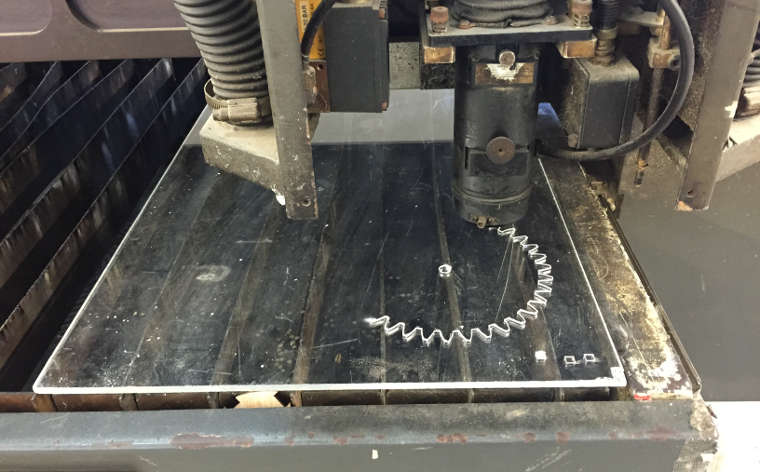

For the base of the machine we used a laser-cut mdf platform.

First fix one of the stepper motors to the mdf base and the acrylic gears on the upper side of the platform. Fix the gears with two nuts. After the gears we did a small laser-cut piece to hold the round base. So, the rotational system is done! be sure that the stepper motor cables are long enough to connect them to the gestalt node and you can be comfortable while doing the programming part.

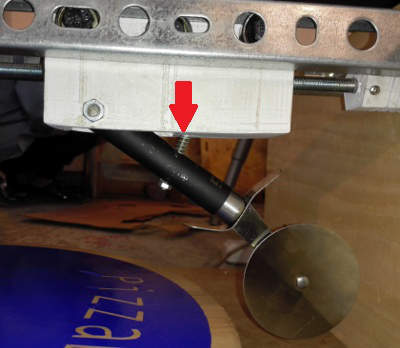

How to join the threaded rod to the stepper motor:

In order to join the stepper motor with the threaded rod we 3d printed a Z coupler piece which is strong but flexible enough to hold the rod. Make sure to print the Z coupler horizontally, otherwise it wont be felxible! Through this assignament I have learned how important is to work interdisciplinary, in the same way components get together to make a machine which can have multiple purposes. It has also been a good trigger to start working on the final project!

Done by:

_PROCESS

_PROGRAMMING THE MACHINE

_WHAT I HAVE LEARNED