week_12 composites

Tasks

- design and make a 3D mold

- produce a fiber composite part

File

download the rhino5 file

is there an alternative to epoxy? - milk it is...

software: rhino, RhinoCam

tools: shopbot, a pot, an oven, a stick, a vacuum pump

materials: skimmed milk, vinegar, baking soda, hydrated lime, burlap fabric, eps, plastic bag;

location: Green FabLab Valldaura (BCN)

making the mold

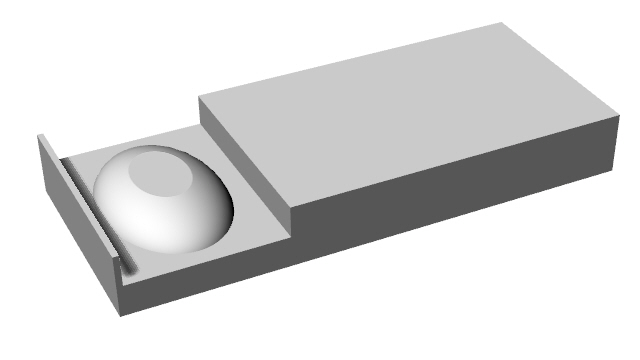

since i'm going to use casein to make glue which is supposed to be water resistant, i want to make a bowl and later fill it with water to see what is going to happen. the negative shape is better to later be used for the vacuum bagging.

the milling of the shape happened in two steps:

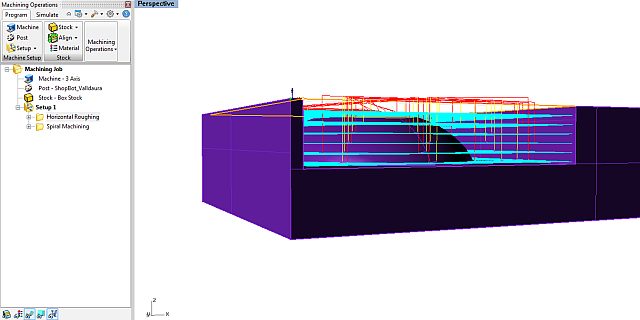

roughing, where most of the material is being removed and the milling bit moving in only two axis, going down in steps, in this case six.

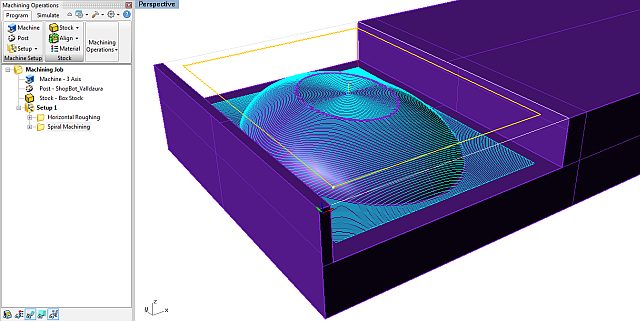

finishing is taking away the rest of the material to create the actual shape. there are various strategies, in this case it's a spiral finishing because my shape is round.the cyan lines in the picture are the path the tip of the milling bit is taking.

the result is very nice, there are almost no marks on the surface. although there was a problem:

- when setting up the strategies i used the same cutting speed in roughing as in finishing. since the path in the finishing is much more complex the shopbot was struggling and eventually lost its position and aborted the job. so i had to restart but before that changing the cutting speed in the header of the g-code.

making the glue

for the making of the glue i follow a recipe from the website of Nuffield Foundation. there are many videos and other material on the web but this one seems to be the most scientific i found, without going too much into detail.

basically you mix vinegar with skimmed milk and heat it up, which seperates the casein from the water. then you strain it and mix the solids with a bit of fresh water and baking soda or other alkaline powders.

composite

first i put some thin plastic film on the mold to make sure everything will be easily removed from the mold. when the mix started to feel like glue i applied it onto the burlap and then everything on the mold. two layers where enough in my opinion.

after no glue was left i put it into a plastic bag and attached the vacuum pump with doublesided tape and started the process.

lessons learned

500ml of milk were not enough to soak the fabric entirely. the glue needs to dry which makes a plastic bag inapropriate, so i took it out the next day, the shape stayed intact. even if it wasn't perfect the structure has enough strength to support a hammer but is not watertight as initially intended. more experiments are neede - and maybe a cow...