Tests

At first I did some tests using small pieces with acute angles to learn the best composite technique. I selected the pieces I designed during the molding an casting week.

With these test parts I tested different natural fibers and resins. For one piece I used sackcloth and for the other one linen. Both of them are joined using a polyester matrix.

Before mixing the components of the matrix I cut the clothes to match the shape of the piece casted. I did that procedure using a pair of scissors and on a trial and error basis.

As non-stick surface I used vaseline and plastic, one for each piece. For the top layer I used perforated plastic for the sackcloth and cloth with linen in order to test both finishes: smooth and rough.

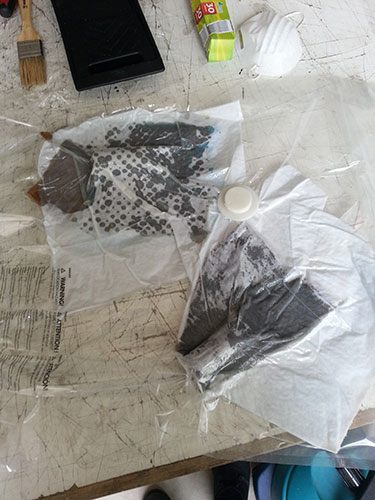

Once layered the composite, before it started curing, I introduced both samples into a cloth vacuum bag.

24h later I separated the mold and the composite. At first I thought it would be easy, but it was not. The linen composite had the clothes bended in such a way it was almost impossible to extract the mold without using a Dremel or breaking it.

Half an hour later I had both composites out of the mold.

As seen in the picture above, the corners were not as good as it should be because I did not cut the cloth pieces properly. Anyhow, the end piece is very strong, I can stand over each one of those pieces without breaking them.

Cordovan Hat

This week's assignment is creating a composite of ~ft2. I did not find any part of the incubator that could be done using composites, so I decided to replicate a Spanish hat: the Cordovan hat.

The mold was machined using foam and a 6mm one lip flat end mill at 1500mm/s. Each layer was 4cm tall, so I had to glue three foam layers in order to have the whole shape.

Trying not to repeat the errors I made with the test pieces, I laser-cut the linen, so each piece had the desired shape.

Before start layering the composite I checked that all the pieces were matching as expected.

Then I prepared the epoxy resin and applied it to the mold and linen.

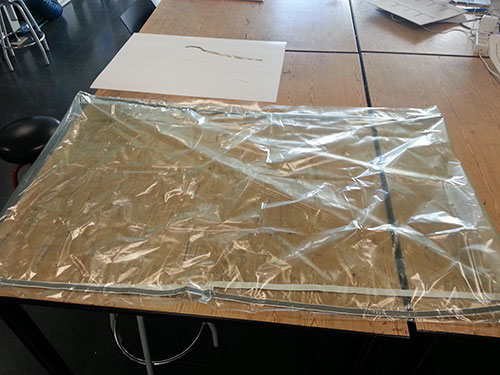

Then I introduced the hat into a self made vacuum bag. Creating the vacuum bag was easier than I thought. With my instructor's help I made the bag in less than one hour. Worth mentioning that it was not necessary for this week assignment nor to fit the hat. Anyhow, learning how to do a vacuum bag might be interesting for bigger composites.

Finally I checked that no additional folds were generated on the process and extracted the air from the bag using a vacuum pump.

Box

A few days later I removed the vacuum bag and the mold from the composite. Now I've got my own and self-made Cordovan hat.