Fab Academy 2015

Fab Academy

How to Make Almost Anything...

How to Make Almost Anything...

This week assignment consist on design a 3D mold, machine it, and cast parts from it.

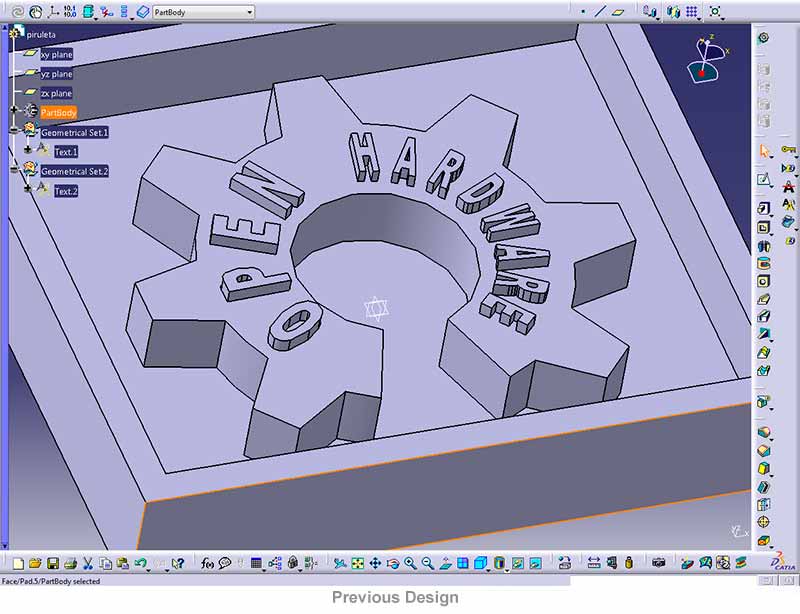

My purpose is to create a mold for confectionery, it can be used with all types of food, at first I wanted to make a round shape using 2 molds but I was advised to start with something simpler, because I hadn't previous experience with molding and this could be very complex to me, so I decided to make the logo "OPEN HARDWARE" in chocolate, something more simple and that I can use in many of the acts that I go.

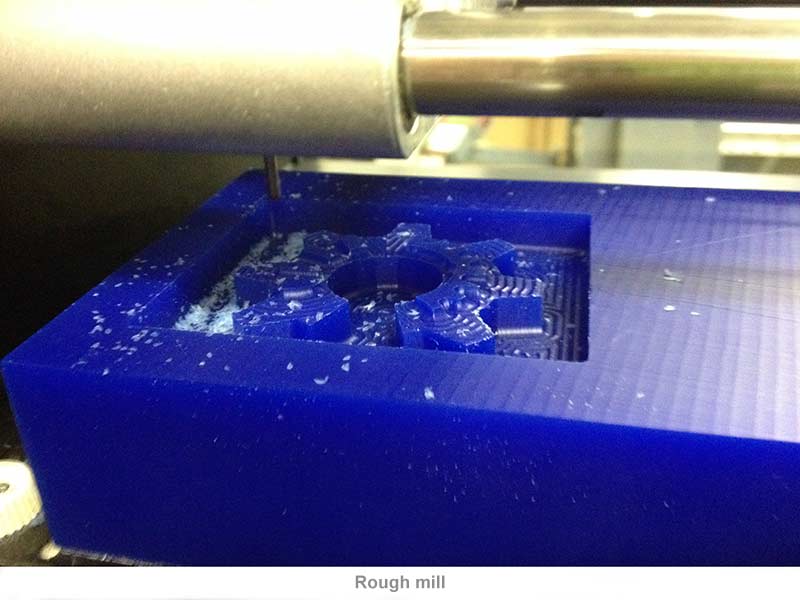

As in previous designs, I used CATIA for 3D model. In this model I entered text before knowing the resolution could be obtained from the "MODELA" so in the final result I have not had good resolution with letters (I'll keep that in mind next time).

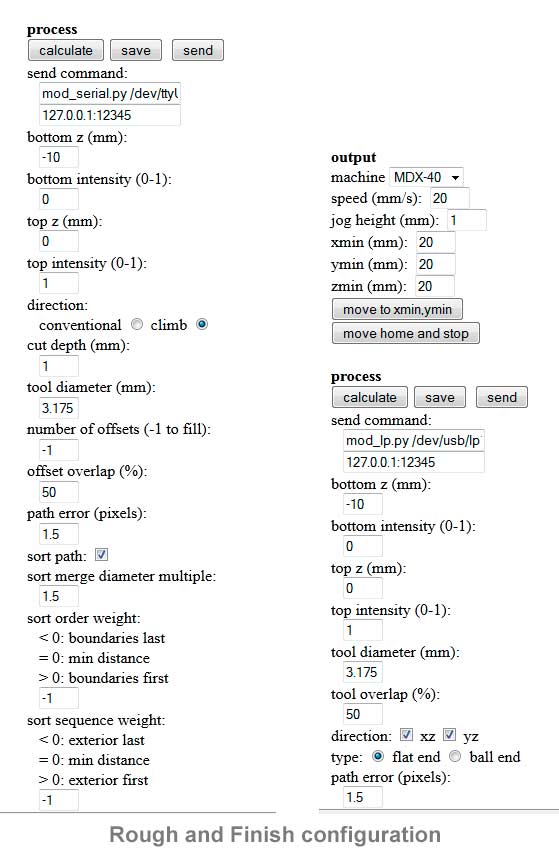

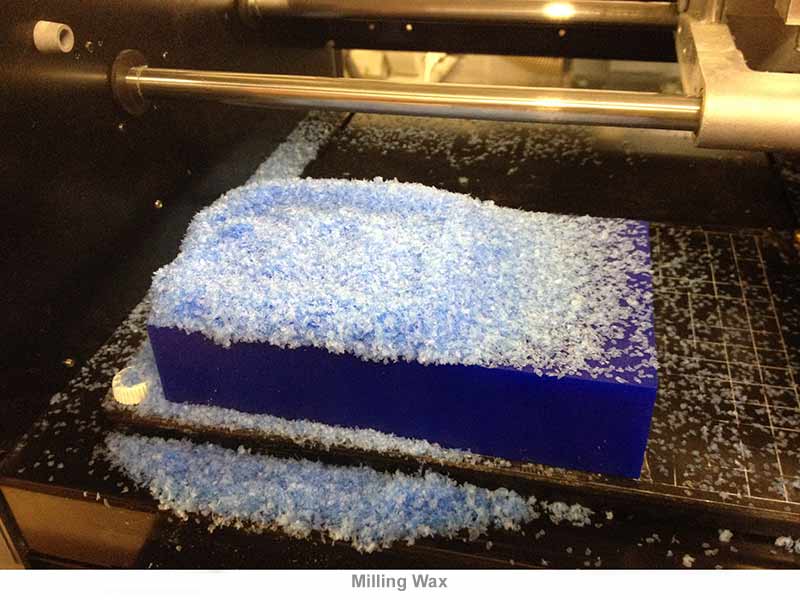

Once I have the 3D design will use the FABModules to mill machinable wax, the FabModule has two strategies "Wax Rough Cut" to make an initial roughingand and "Wax Finish Cut" leaving a semi-polished finish.

To make the piece I will use two strategies work, the first will remove most material and the second (slower) give an almost polished finish.

For the previous milling cutter I used a 1/8 inch (3.175mm) it was not enough to finish the lyrics, so once the design is done, I returned to run the job using a 1/32 inch mill using "Wax Rough Cut" strategies and canceling the job (manually) once had milled to the height I wanted.

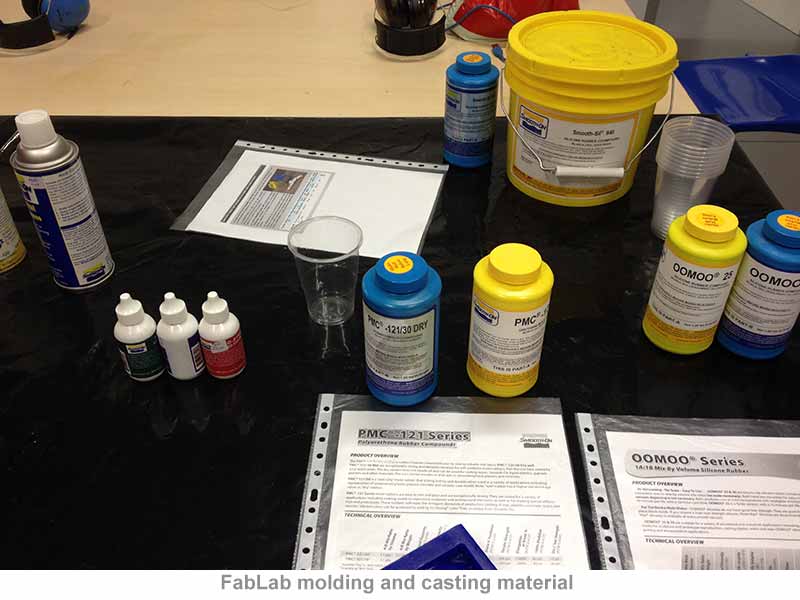

With full wax mold is just pour the silicone, in my case, I use a food silicone but I am impressed by the enormous variety of silicones and resins exist, I've really learned a lot about this and now I know many types of resins that can help me to make various objects, in the future based on usage I want to give.

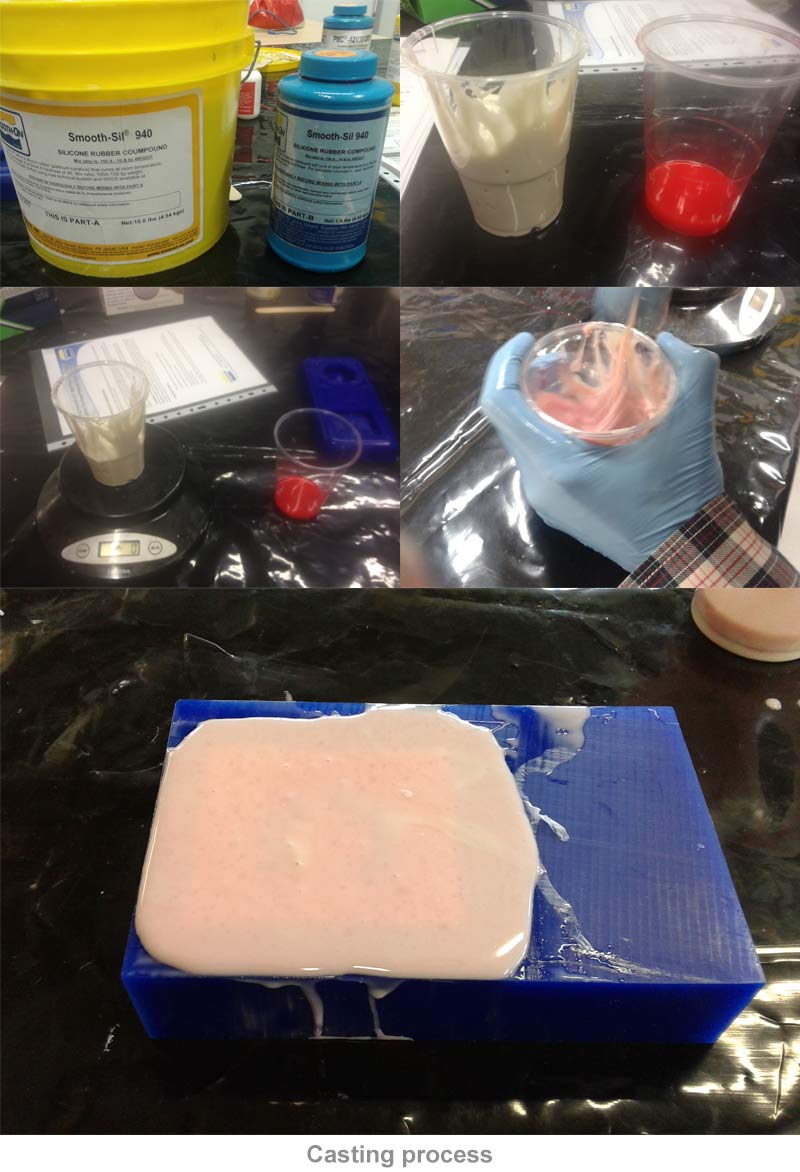

As I said, in my case I use food grade silicon, more specifically "Smooth Sil 940" this is a bicomponent silicone mixture with a ratio 10/1 (10 parts of A and one B). We will measure these two parts separately and once sure to have the correct relationship, mix until getting a homogeneous union, once the mixture ready, it is poured into the mold leaving it to stand for 24 hours at the end to a definitive cure is necessary to put the mold in oven at 100 degrees for 4 hours.

With mold ready we can pour into this any food (chocolate, gelatin ...)