Fab Academy 2015

Fab Academy

How to Make Almost Anything...

How to Make Almost Anything...

This week we have to make a simple task, MAKE SOMETHING BIG!!!

To build something great, we will use the CNC machine, in my case, I build the table on which anger placed the aquarium (final project).

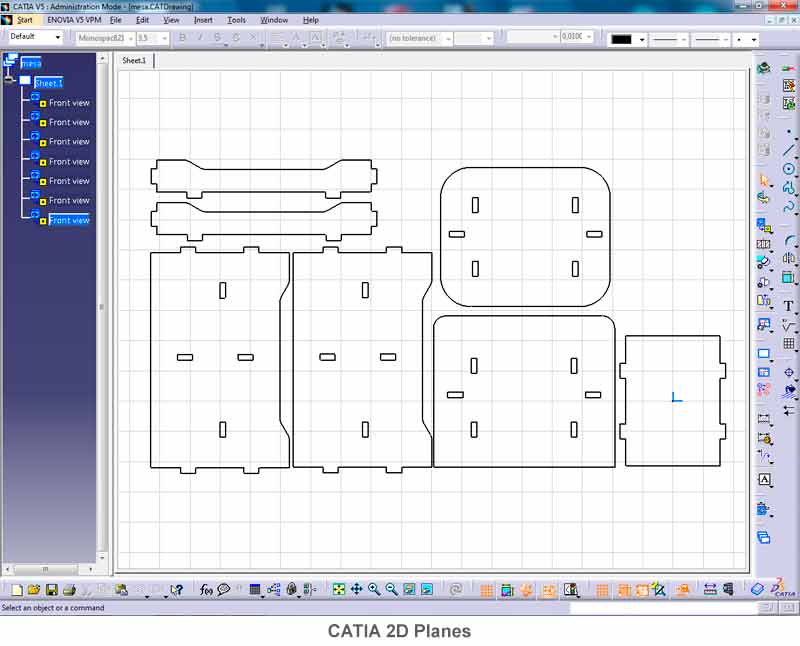

I've done the previous table design with CATIA, but this design is a 3D design, something that is not valid to make the cuts with CNC machine, so I had to extract the 2D drawings for milling tables. Extract the planes with CATIA is very simple, you just have to select the face you want to extract the plane on drawing editor.

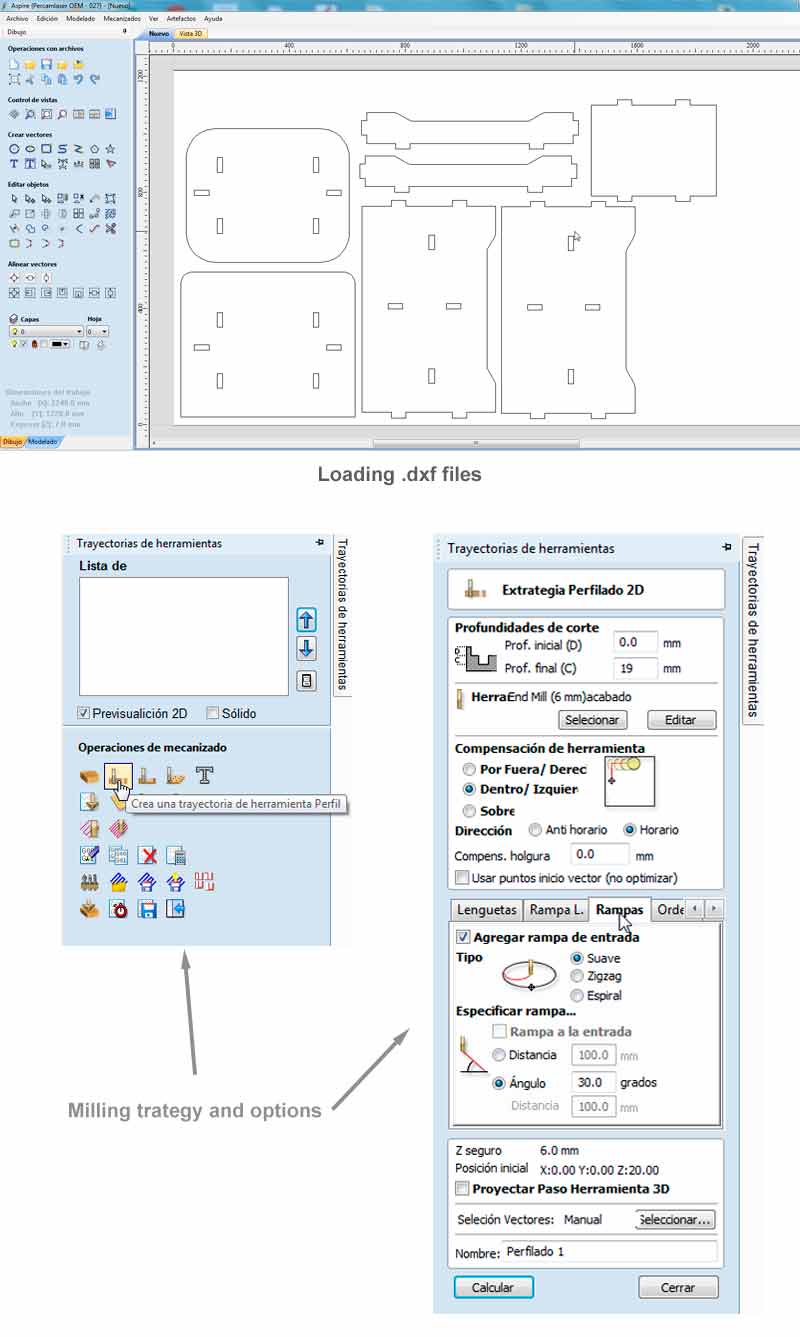

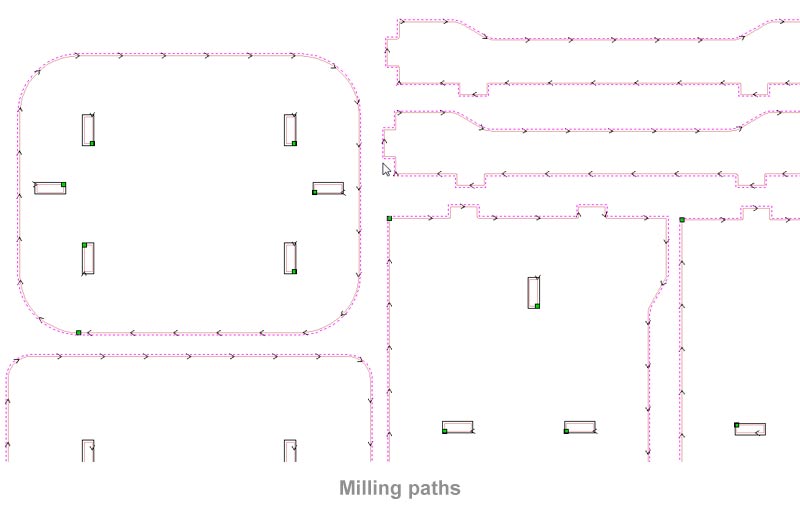

Once extracted drawings in .dxf format, we must bring the designs to the program that generates the milling strategies, in my case I use Aspire. This is a program where you can import .dxf modify and create cutting strategies.

For the table I use only cutting strategies but there will be two different types of cutting, a cut from within (for slots) and from outside to cut the perimeter of the piece.

To cut DM 20mm I use a 6mm tool and I set up the machine with these characteristics:

Once created the milling strategies, you just have to load into the machine the various files and launch it. Previously, you must set the height (Z axis) and the initial position (XY axis) on the machine. For milling table, I'll use a "TECAM 500" with a 6mm milling cutter.

Before you start milling, needs to be done some preliminary operations:

Once milled boards, just left the assembly,for that, you just have to put the pieces orderly and hitting with a small hammer to fit.

To conclude the work and make the table more durable, I'll paint it using a primer and black lacquered.