C o n t a c t F a c e b o o k S k y p e I n s t a g r a m P i n t e r e s t H o m e

05. 3D scanner and printing

Design and 3D print a small object that could not be made subtractively and 3D scan an object

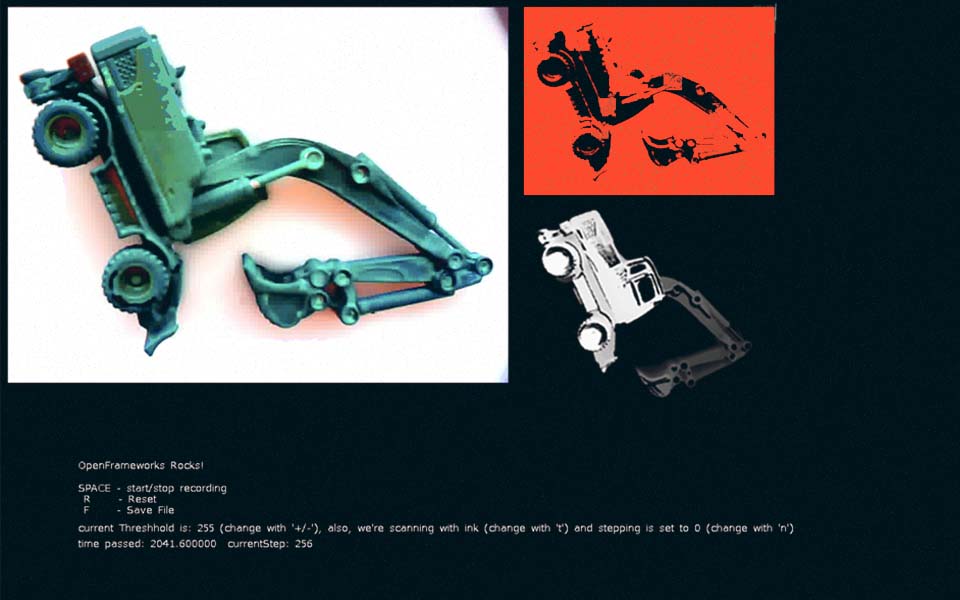

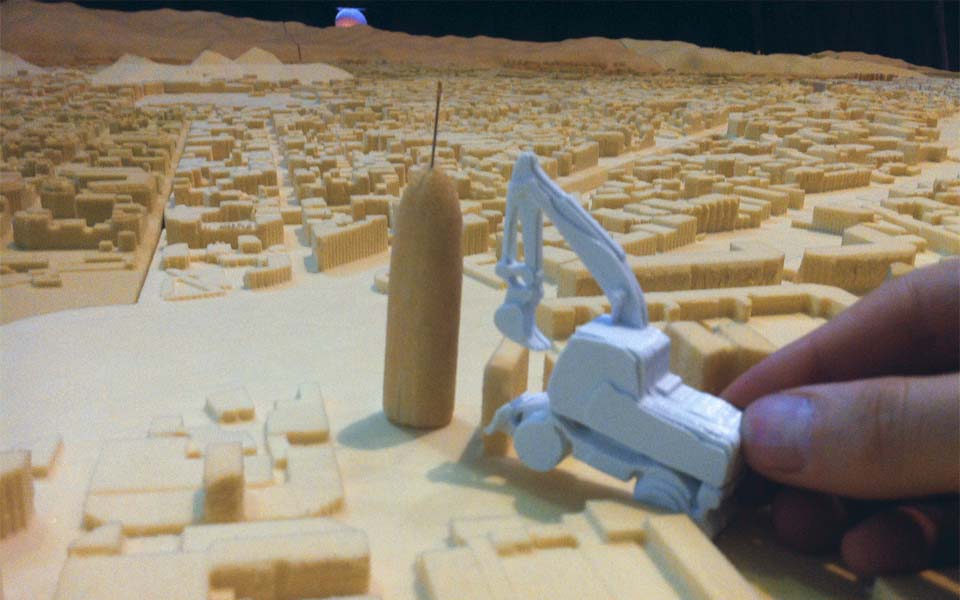

Using the Kinect scanner and Skanect software, I attempted to scan a toy digger. I learned very quickly that the Kinect doesn't pick up very minute details at that resolution. To resolve this, I decided to scan with a fluid. The idea behind the process is capture the silhouette of an object easily when it is surrounded by a high contrast fluid, such as milk or ink.

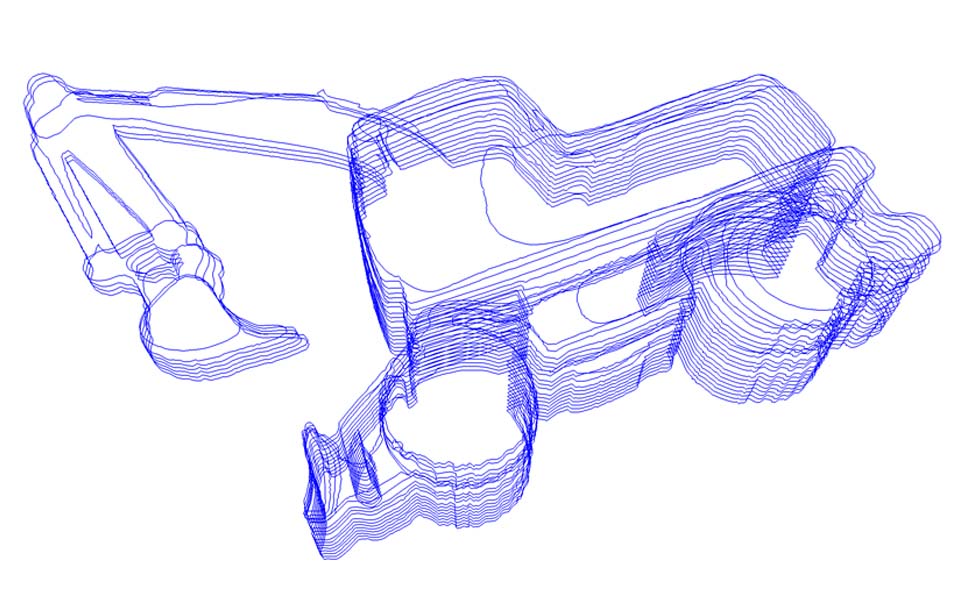

The toy digger was placed into a container and a composite height map was compiled using the Fluid Scanner software every few spoonfuls of milk. This process was repeated for the back side of the toy as well. Unfortunately, the resulting file exported from the software only produced an .xml file which, due to very little documentation online, was difficult to convert into a 3D object file. To go about this, screenshots were taken at certain constant intervals and imported into Rhino where the silhouette of the object was manually extracted and positioned at constant intervals.

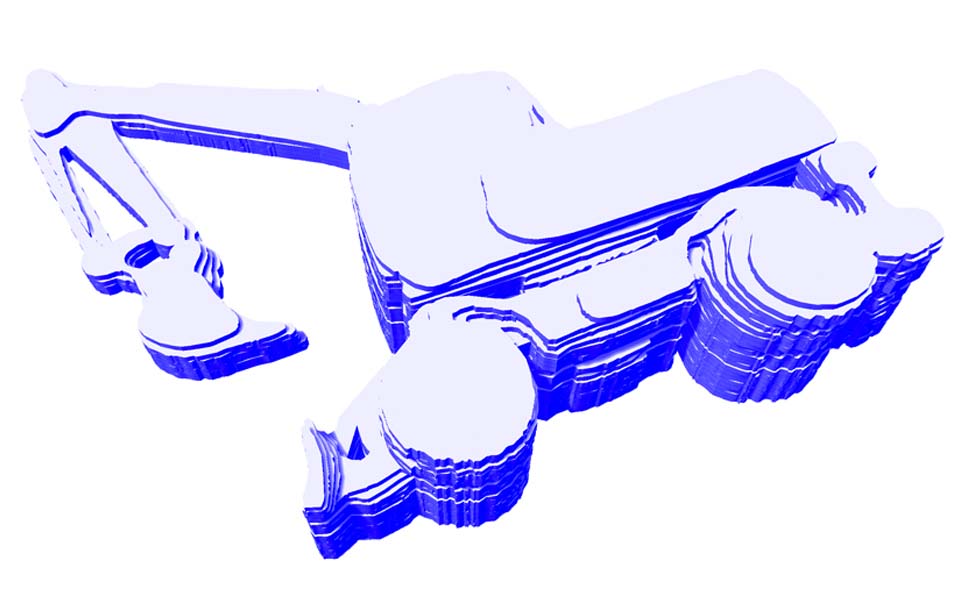

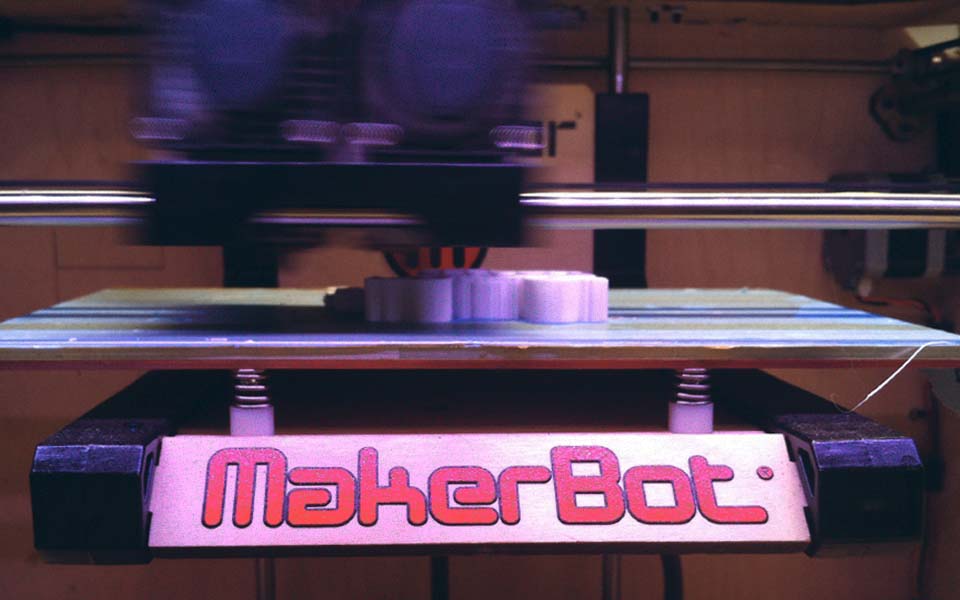

In order to obtain a solid mesh object, these polysurfaces were joined and combined to produce one solid mesh. One thing I had to consider for printed was orientation of the toy. The makerbot cannot print objects with cantilevers of 45 degrees and higher. Because of the geometry of the toy digger, it was necessary to print it on the side with the most surface area which is on the side of the digger, which resulted in some discarding of layer information on one side of the model.

The mesh was checked for any openings and I attempted to 3D print the resulting shape. Expectedly, the 3D printed object from the milk scan was not a detailed as the original digger. For all those attempting to do the milkscanner, head this warning: there is very little documentation on how to extract files from the Fluid Scanner software. Unless you are prepared to do a fair amount of manual CAD work, don't milkscan ^_^

Download the corresponding files here.