Make Something BIG

Assignment

make something big academy.cba.mit.edu

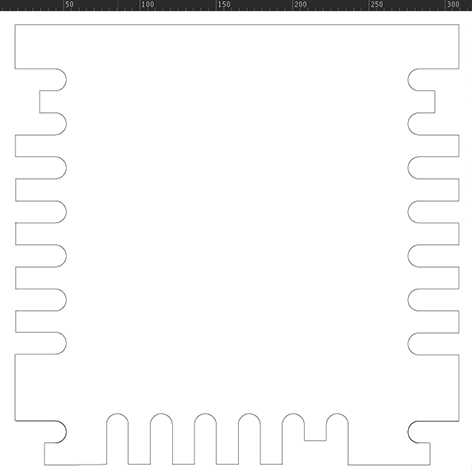

For this assignment I started drawing in Illustrator. I was originally going to try to create different types of joints but after taking the design into Rhino I decided to keep it simple!

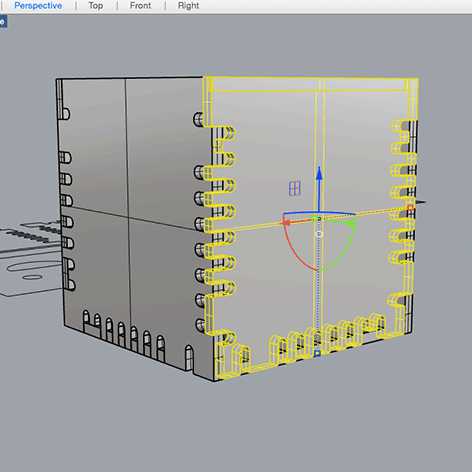

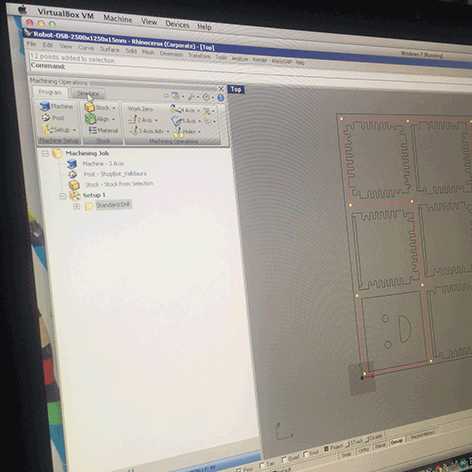

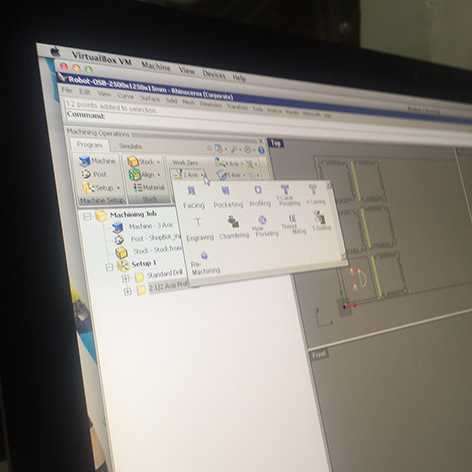

Imported the Illustrator file into Rhino & recreated the joints in the robot head box to make sure the pieces fit properly. Then added a 15mm thickness following the OSB board specifications & created the lip to be able to add the box top (in this case is a robot face). The eyes & mouth will make it easier to open & close the box to store things!

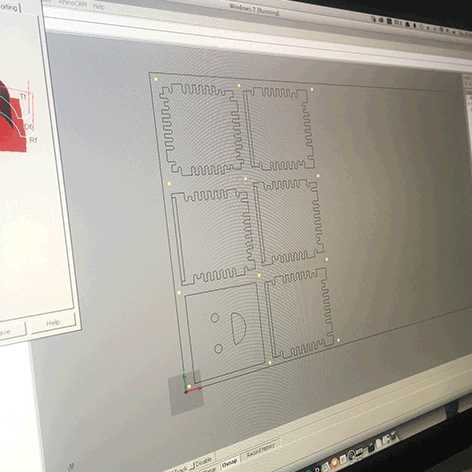

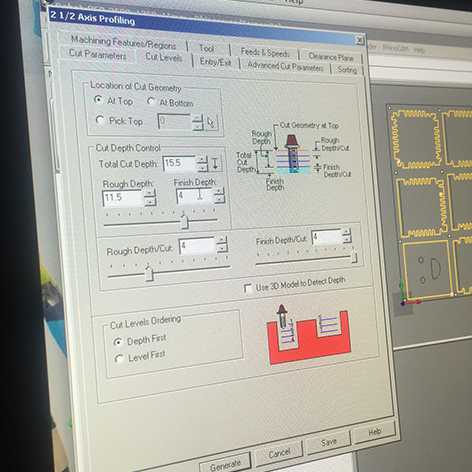

Nesting the pieces into the 2500mm x 1250mm OSB board is an easy task since the pieces are square & simple

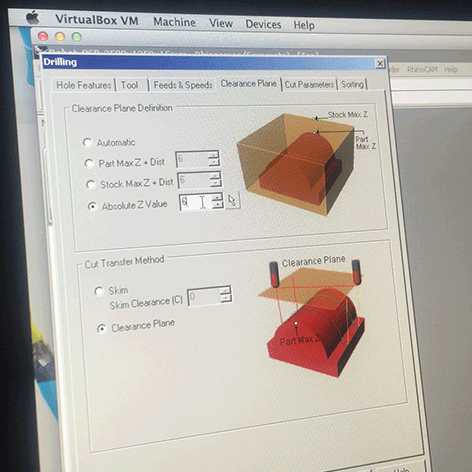

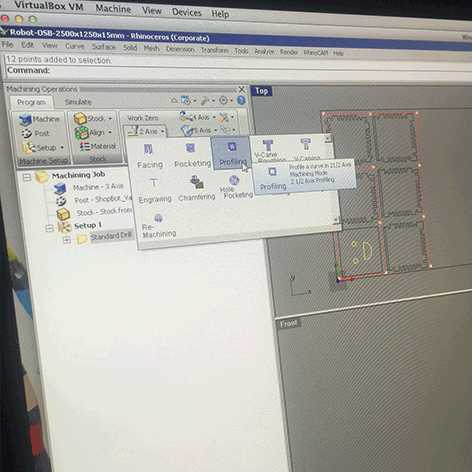

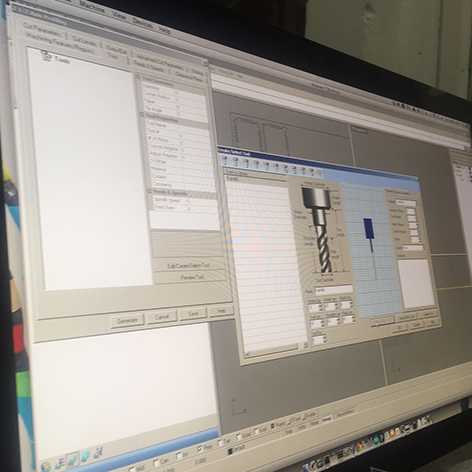

One for the screws, one for the pockets & the other one to test the joints to make sure they all fit before doing the other two boxes.

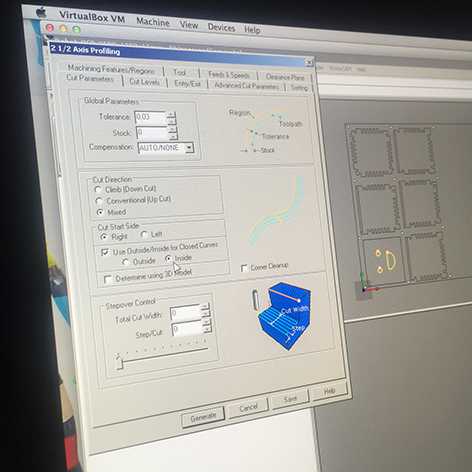

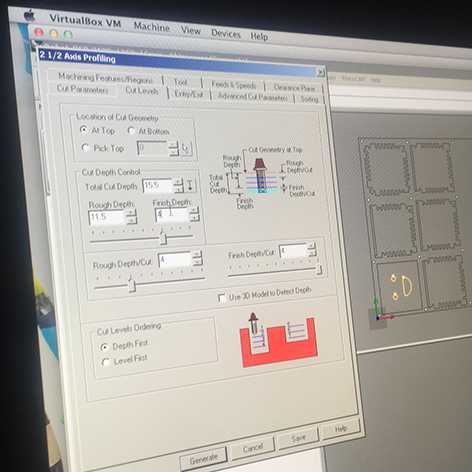

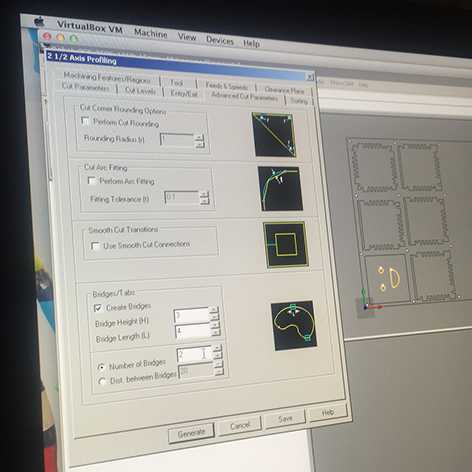

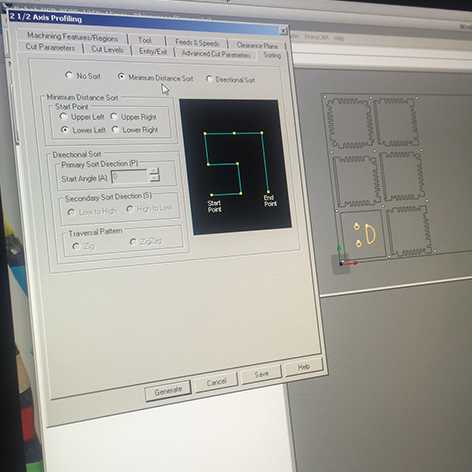

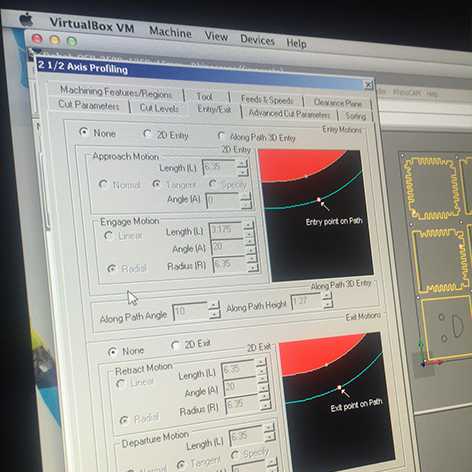

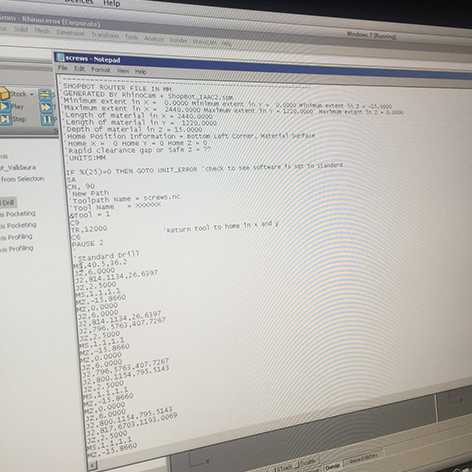

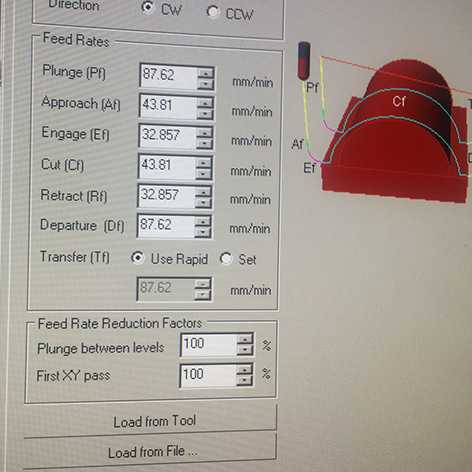

Once set the screws, the pockets, the face & joints paths with gcode it is ready to be sent to the milling machine. The gcode files ready to GO!

Preparing the milling machine to start the job! First added the OSB board on top of the sacrificial board & set up the zero point manually to the top left corner of the board. Then secured to board running the first milling job with screws! Then added manually the screws to the board!

The milling was smooth but the OSB board material is super low grade and the joints which fit perfectly broke due to the bad quality of the OSB board. In the second milling round I modified the seams to be a little more spaced out (0.02 mm) so it would no break the material.

The final result after loads of sawing, sanding & smoothing the corners to make it child safe was pretty good! In the future I will use another material but the OSB was good for a test!