03.computer-controlled cutting

material

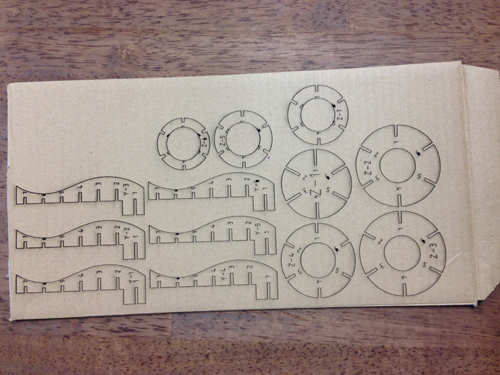

We do shopping many things on web frequently,so we surrounded by cardboard than before. For this lesson ,though it doesn't have strength , I have used a box of ZOZO that is a famous fashion EC site in Japan.

making data

I tried several ways to make pieces.

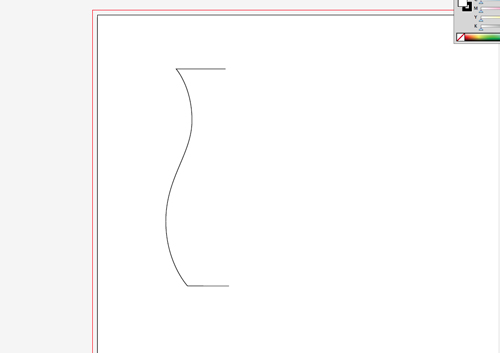

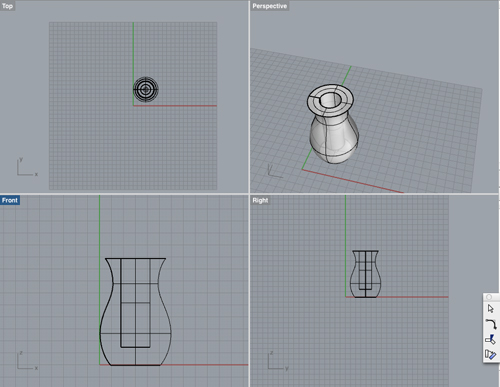

type1:jar

First, I made a path in Illustrator,and exported the date to Rhino. In Rhino, I made the path into 3D model.

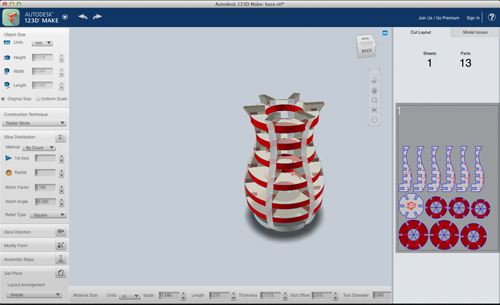

Then import the data on 123D, I adjusted thickness of the material.

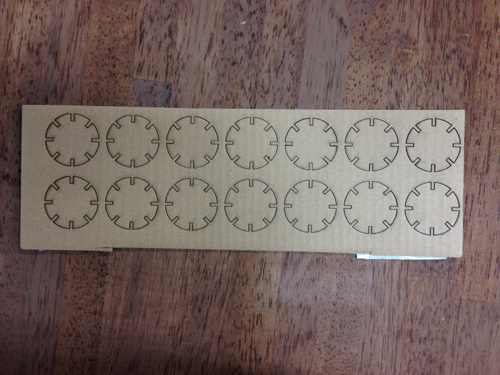

type2:Pieces of the circle

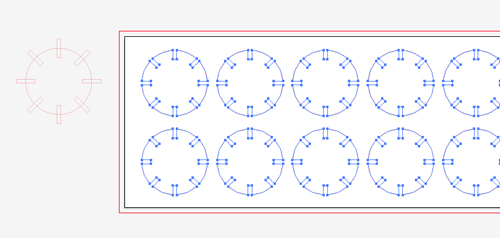

I made the path using "symbol" similar to clone in Inkspace.Path can't cut when we use symbol.

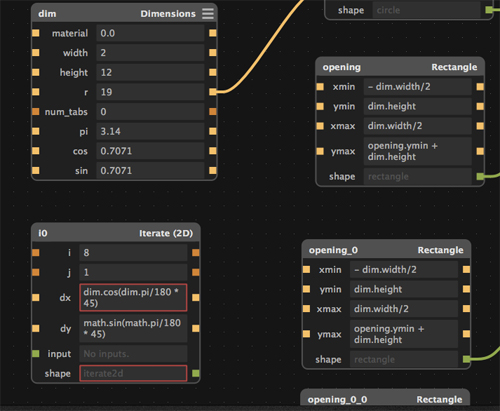

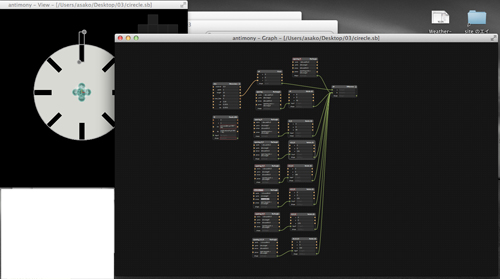

After that, I was going to make by antimony the same thing that I made it in Illustrator. Because I wanted to do iteration while rotating the form, I wrote a code of the radian, but it didn't work.

I gave up programing it, made 8 rectangles on circle . Even more, unfortunately, I could't export PNG, then I decided to use Illustrator's one.

cutting

I cut using UNIVERSAL and Epilog laser cutter. The setting is as follows. material: cardboard 2mm thickness setting: UNIVERSAL power:100% speed:25% profile:Paper 1.8mm Epilog Power:50% speed:50%

assemble

type1

1st and 2nd prototype,ditch ware too small. So I was back to 123D and adjusted thickness again. It was slightly still tight, but was able to finally make it up +0.4mm(123D setting) from thickness of material.

type2

Pieces which I made in Illustrator was good.