Week 12

Composite I: Dove

Machine: Laser cutter EPILOG Zing16 30W (Vector setting: Speed 50, Power 55, Frequency 2500Hz, 500dpi)

Materials: 40cm x 29cm Cardboard (4.5mm thick), Glue, Resin, Felt, Marbles(17 mm in diameter), Thin plastic bag

Software: Fusion 360 for 3D modelling, 123D Make for converting the 3D model into slices, Inkscape for editing the pdf data

Making the Data

(all photos can also be viewed here. View/download the 3D data here)

I made the 3D data of the dove and created a cavity in it for placing marbles inside, to make the dove rock back and forth when it was pushed. I used 123D Make to create the cardboard core of the composit. In stead of interlocked slices, I converted the 3D model into stacked slices, so that I could also make the two-sided mold to compress the composite(photo 61 to 63). I opened this pdf with Inkscape and drew the outlines of the mold for each slice. I also drew offsets of the dove’s outlines (Path Inset) to make room for the felt that will cover the core .

Making the Core and Mold

After cutting all of the slices with the laser cutter I glued them together. When I put the marbles in the cardboard core, I noticed the cavity was too wide which made the dove’s movement unstable, so I added some cardboard to narrow the width. I inserted three marbles and also put masking tape on the marbles to muffle the rattling noise. The video below shows how the cardboard dove moved.

Making the Composite

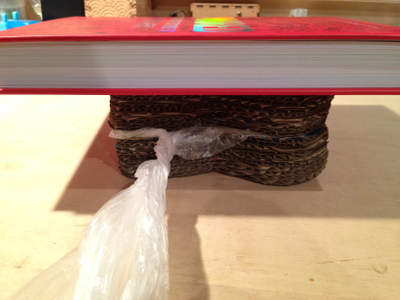

For making the composite, I roughly cut the felt so that it matched the shape of the cardboard core. Then, I sewed 2 sections at the bottom to make it easier to insert the core. I soaked the felt in the resin, put the core in, pressed the felt together, and placed it in a bag (so that it wouldn’t stick to the two-sided mold). After inserting it into the two-sided mold and adding weight on top, I waited about 20 minutes for it to cure.

Mistakes

- Though the ratio of felt and resin had to be 1:1, I just soaked the felt in the resin and didn’t measure them. The composite turned out rock solid, but it looks like I used too much resin.

- When the composite was pressed, the felt was pinched and made the edges stick out (photo). I should have created a larger mold or tried compressing it with bags of water as Neil mentioned in the lecture. Somehow I was able to I cut of the hard edges using scissors and a small knife.

- Since the composite was compressed the width of the dove narrowed and made it unstable. It can hardly sit on its own, let alone rock anymore :( I should have made the bottom side of the dove wider.

(all photos can also be viewed here)

Composite II: Bowl

Machine: Laser cutter EPILOG Zing16 30W (Vector setting: Speed 50, Power 55, Frequency 2500Hz, 500dpi)

Materials: 40cm x 29cm Cardboard (4.5mm thick), Clear resin (Crystal Resin NEO), Thin polyester fabric, Food wrap

Software: Fusion 360 for modelling, 123D Make for converting the 3D model into slices

Making the Data

In Fusion 360 I drew a sketch and used Sweep to make a solid. Then I made duplicates of this solid by using Circular Pattern and combined them to make the mold of a bowl.

(all photos can also be viewed here. View/download the 3D data here)

Making the Mold

This time instead of making the core of the composite, I just made the mold. The process is the same as when I made the dove: I converted the stil file to slices, cut the cardboard, and glued the slices together.Making the Composite

I covered the cardboard mold with food rap so that the composite wouldn’t stick to it. Then I cut the fabric into 5 circular pieces (275mm in diameter). In the middle of the layers of fabric I sewed and loosely tied white thread at two points to prevent the layers from shifting. I measured the fabric (8.7g) and then I poured 15g of clear resin and soaked the fabric in it. I pressed the fabric on the mold, removed the white threads and covered it with food wrap. I compressed the mold by placing it into a bucket and putting a bag of water on it, and left it to cure for a few days.

Mistakes

- Since the fabric stretched, the layers of fabric did shift a little.

- The composite keeps it’s shape as a bowl, but it can be easily folded in half and isn’t so sturdy. I should have used thicker fabric.

(all photos can also be viewed here)