Week 7:

Computer-Controlled Machining

As a child, Lego and other construction games were my favourite to play.

The process of building objects by connecting pieces present an endless amount of creativity.

This toy - is a combination of simple design and helpful tool at home

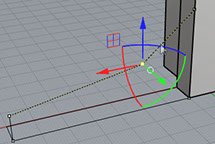

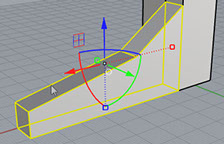

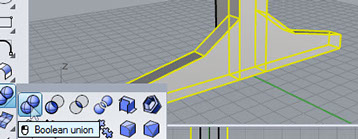

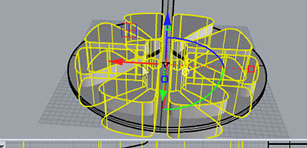

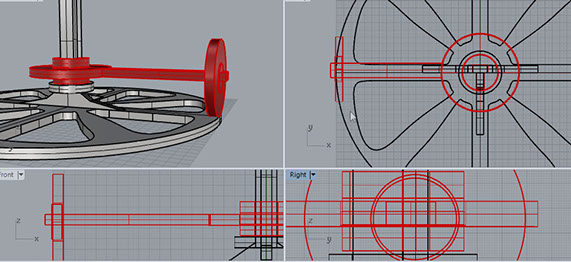

The process started in the middle with the creation of the base and legs, using simple polylines and boolean operations .

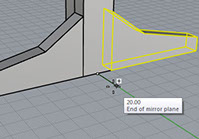

Mirror - one of my favourite tools in all designing programs =)

Extrude curve -> Straight !

And Polar array to help!

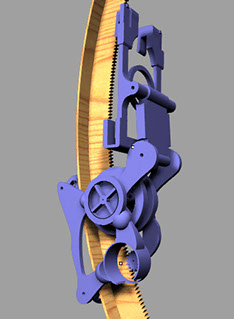

There are no bearings, as it is expected to work with little space between the rolling components .

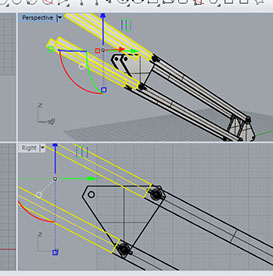

That thing was more interesting for me..

It's took me a while to realise how will it work, despite the fact that the example for object was a simple lamp.

I did some changing of the basic mechanism to make it bending how i wanted.

The rhino - is wasn't a comfortable software for 3D as I was expecting, coming from a background of photoshop,but some tricks is helps a lot to make your objects look how you like it to be .. The function <Project> for instance.

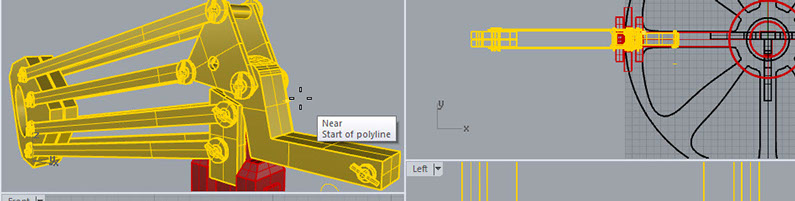

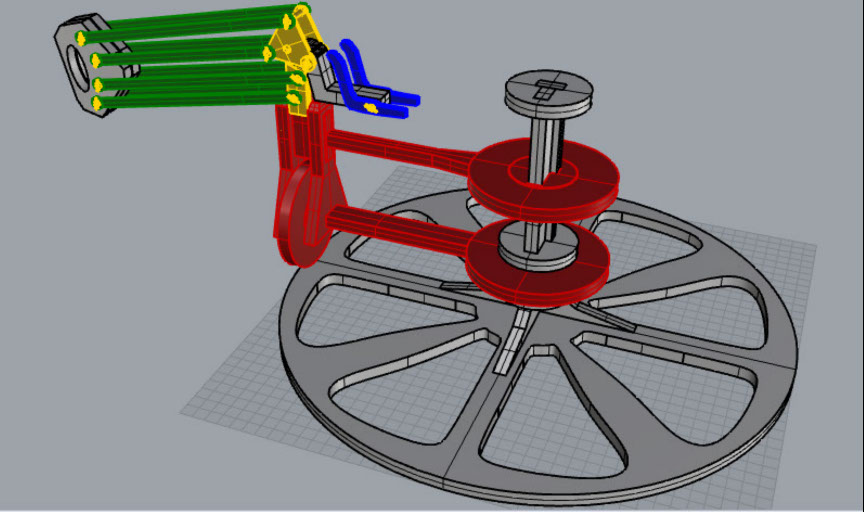

My Portable station for the capture 3d pictures from phones and simple cameras!

This design is meant to be made on a 3mm sheet of wood

To build it I am going to use a few different materials and machines probably .

But to the test of the model I am going to cut it with laser form carton board .

To set up the laser I printed a little part of model to understand how much power and speed I need to make optimal cuts from both sides of the layer.

This test as done 4 times.

but something burns anyway..

even the second side of the carton was not cut completely

it's happened because of some confuse with importing of my .dfx files from rhino to the laser, little circles after export consists of a plurality of points.. Best solution is to convert files to .il

Later i found problem, the little halls was not joined and laser did many points almost on the same place , next time ill check my file twice before to send it .

Tomorrow, I will make it again.

.jpg)

.jpg)

.jpg)

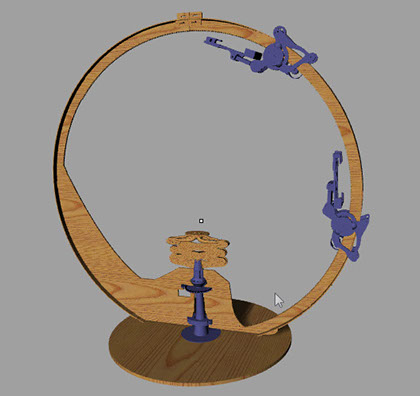

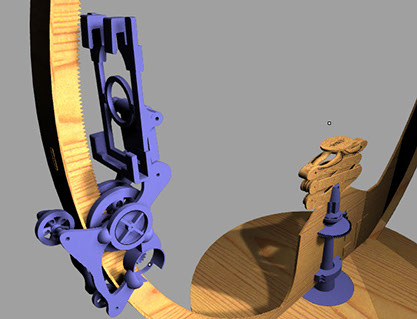

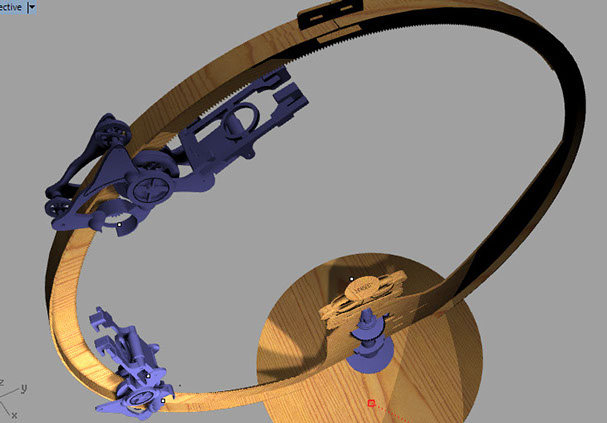

Here is my another project

of full automatised 3D scanner ..

This one gives me great experience!

I had a chance to play a lot with settings of machines to realize this project!

All the gears and wheels that was needed to build this construction makes me a good experiments with laser cut and 3d printer possibilities ..