12. Composites

design and make a 3D mold (~ft2), and produce a fiber composite part in it

Make a Skateboard

Making molds

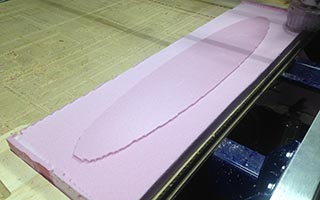

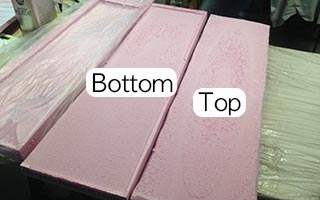

I designed two molds(top and bottom) has a opposite curvature. The composites (body of the skateboard) are going to be between top and bottom molds and make pressure with weight. I designed with Autodesk Inventor, It was simple.

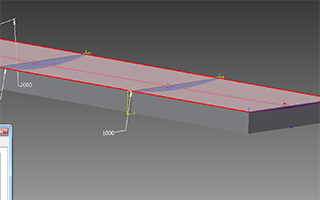

make a curvature - using loft tool from sketches on the different planes |

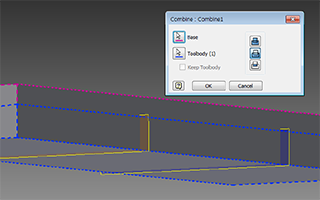

make two molds - using Combine tool for cut a solid from another. |

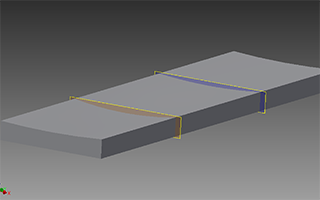

bottom mold |

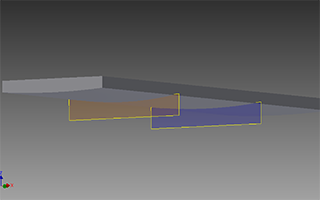

top mold |

Test with smaller version

I made a 1/10 smaller version of skate for test the procedure. I made molds by hand using knife. laser1.6mm plywood

Procedure

making mold - IsoPink foam is cut by a knife easily |

wood gluing between the layers |

cut fiber-glass using sharp scissors |

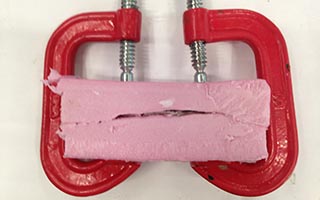

Pressure by clamps |

result

It was glued and bent nicely |

but It got twisted because of the shearing force made by clamps |

Laser cut

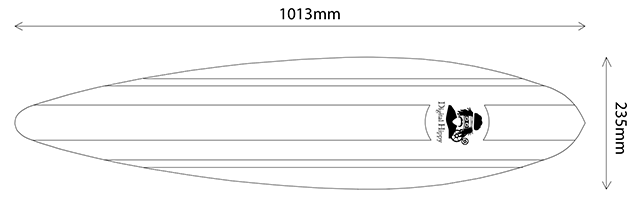

I designed pin-tail longboard using illustrator.

Engraving the top of the plywood |

6 layers of the 1.6mm plywoods |

Making mold

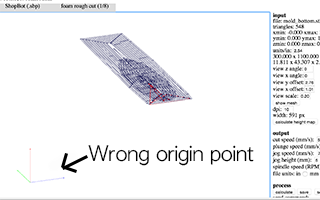

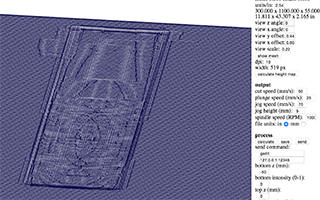

I made the toolpathes on fabmodules.org. I imported stl file, caculate height map and make a toolpath. but there are problem about making origin like the picture below. So I used another way to make toolpaths. I made a png file in photoshop which has a gradient, and make a toolpath from the png file on fabmodules.org.

-

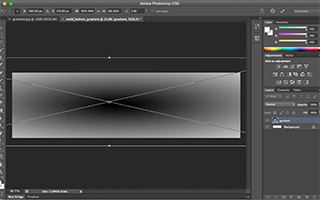

Make a png file - photoshop

Make a new document which size is 300mm X 1100mm, place the gradient png file download from web (It is just a simple gradient image). Modify the picture for making gradient what I want. -

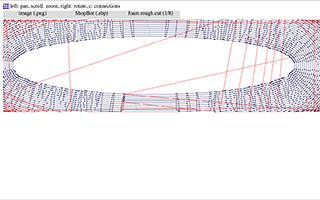

Make toolpaths - fabmodules.org

Input to png file, Output to sbp file. Make both roughing and finishing. After saved both of them, invert images to make opposite side of the mold. here are the properties I used.

Roughing

cut speed = 100, plunge speed = 25, jog speed = 75, jog height = 5, file units = mm, bottom z = -15, top z = 0, tool diameter = 12.7mm, number of offsets = -1, offset overlap = 50%

Finishing

cut speed = 100, plunge speed = 25, jog speed = 75, jog height = 5, spindle speed = 14000RPM, file units = mm, bottom z = -15, top z = 0, tool diameter = 6mm, tool overlap = 50%, direction = xz, yz, type = ball end, path error = 1.5 pixels

|

|

|

|

|

|

|

|

|

|

Safety

Article - Safety and Health Concerns : Fiberglass

Fiberglass is a substance made when small glass particles are extruded into thin strands of material used to reinforce polymer products or as insulation.

Dealing with fiber-glass and resin can cause health problems. So It’s very important to wear protection equipments. Our lab have 3M professional mask and latex gloves. I didn’t feel any problem after doing assignment.

|

|

Fabrication

-

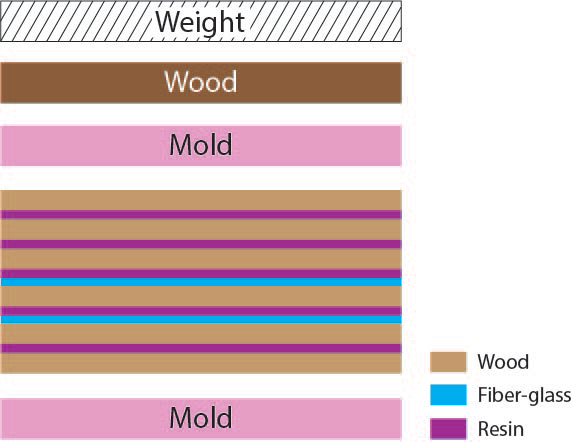

Do simulations : resin quickly harden, It is difficult to modify something when I start painting it. so before starting, It is important to check every procedures. Here is the procedure.

mix resin and hardener(100:1) -> bottom mold -> plastic bag -> wood -> resin -> wood -> fiber-glass -> resin -> wood -> fiberglass -> resin -> wood -> resin -> wood -> resin -> wood -> plastic bag -> top mold -> wood(this is for distributing the force) -> weight.

-

Mix resin and hardener

I used 250g of resin. It was enough to make one. more hardener makes it harden faster. -

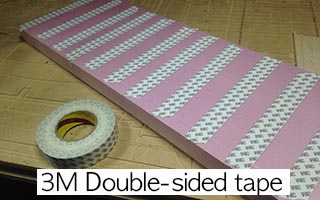

Plastic bags between woods and molds

It makes easier to take it out from molds. resin can harden between woods and molds. -

paint it fast : resin is gonna be hard fast. However, be careful your clothes.

-

Fiberglass : paint it until it goes transparent.

|

|

|

|

|

|

slightly bent

strength test

It’s good day to composite