9. Molding and Casting

design a 3D mold, machine it, and cast parts from it

Making "Hugging Teddy bear" : softrobotics

For this assignment, I have two weeks. I try to make hugging Teddy bear with PneuNets Bending Actuators. This mechanism is inspired by softrobotics the video below.

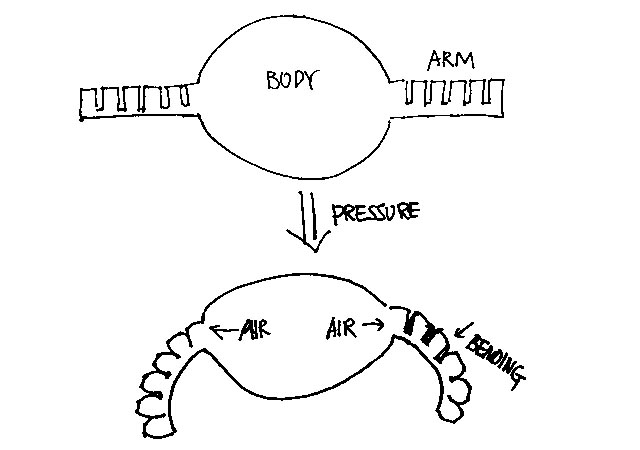

Idea sketch

It’s very simple mechanism. there are two parts: body, arms. Body looks like ball and contains air. If I hug Teddy bear, the body will get pressure. And then Teddy bear also hug me because the arms are bended when the air goes inside.

Making Mold

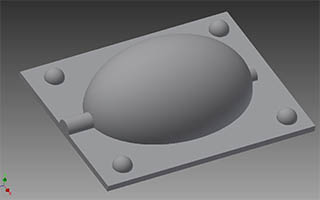

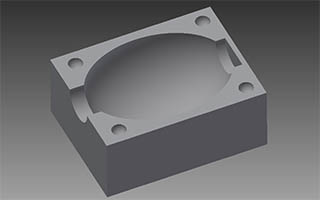

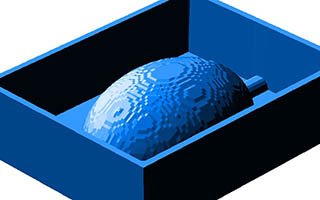

Design Mold : body

I want to make a ball which has empty space inside. I split the ball to half and going to stick it together. I made two mold parts; bottom part is outside of the ball, top part is inside of the ball

|

|

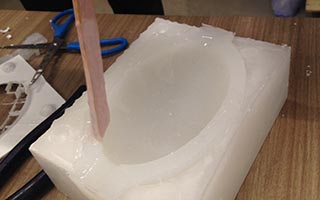

Making Wax block

We have a suitable wax for Machining, but It was only 4mm thickness. I melted it with a heat gun. this list is the needed things for making thicker wax block.

-

wax blocks to melt (I also the classmate’s used wax chips after being machined.)

-

2 Molds for a Wax block (Acrylic box: Laser cutting)

-

heat gun (oven would be much better)

-

pot

-

refrigerator (much faster to cool it)

|

|

|

|

Download (Acrylic mold for wax block pdf, dxf file : 170mmX130mmX70mm)

Failure

-

first time I tried to melt each surfaces of the two blocks and glue it together, but it doesn’t work.

-

Masking tape let wax leak. I used duck tape after

|

|

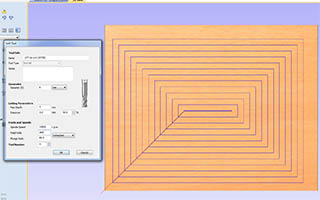

Flattening wax

for machining, I made the wax flatten using shopbot and Vcarve Pro. make a pocket toolpath 3mm depth using upcut endmill 1 flute.

pocket depth = 3mm

Diameter = 6.0mm

Pass Depth = 4mm

Stepover = 3.0mm (50%)

Spindle Speed = 14000rpm

Feed Rate = 200inches/min

Plunge Rate = 60inches/min

|

|

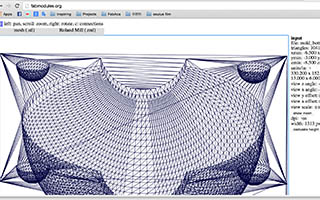

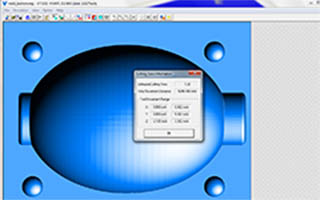

Machining Mold

Make a tool path using Modela Player 4.

-

import stl File

-

change the origin to right way, make sure the scale of the material

-

choose Z-top surface to cut

-

Cutting Area : Check ‘Partial’, lower left X:0, Y:0, Upper right X:170, Y130

-

Cutting parameters

-Roughing

Tool : 3mm square

XY speed : 30mm/s

Z speed : 10mm/s

Spindle : 7000rpm

Cutting-in Amount : 1mm

Path Interval : 1.8mm

Finish Margin : 0.2mm-Finishing

Tool : R3 ball (6mm diameter)

XY speed : 30mm/s

Z speed : 24mm/s

Spindle : 7000rpm

Cutting-in Amount : 0.2mm

Path Interval : 0.2mm

Finish Margin : 0mm -

Create tool path : Roughing takes about 3hours, Finishing takes about 2 hours

|

|

|

|

bottom mold

top mold

Making arms (using 3Dprinter and open-source design file)

I 3d-printed mold files and Casted it (I used ke1402. Next time, I want to modify my design and make with CNC. I followed instructions and downloaded mold stl files from the link below.

http://softroboticstoolkit.com/book/pneunets-bending-actuator

-

3D print the downloaded stl files

-

Casting : Mold Star® 20T Silicone

Mold Star® 20T is an easy to use translucent platinum silicone that is mixed 1A:1B by volume (no weighing scale necessary). It features a relatively low viscosity and vacuum degassing is not required for most applications. Pot life is 6 minutes and cure time is 30 minutes at room temperature.

|

|

|

|

Assemble

I made two same body parts and glued it with silicone. then glued it with arm parts.

Body part casting (2EA)

Body part casting (2EA) |

glue it with silicone

glue it with silicone |

glue two casting parts

glue two casting parts |

body part Assembly

body part Assembly |

It was very effective to clean the surface with acetone before gluing it

It was very effective to clean the surface with acetone before gluing it |

|

Failures

it was really hard to take silicon cast out from the mold which is wax. I used WD7 which is penetrating oil. It was much better to take it out

|

|

|

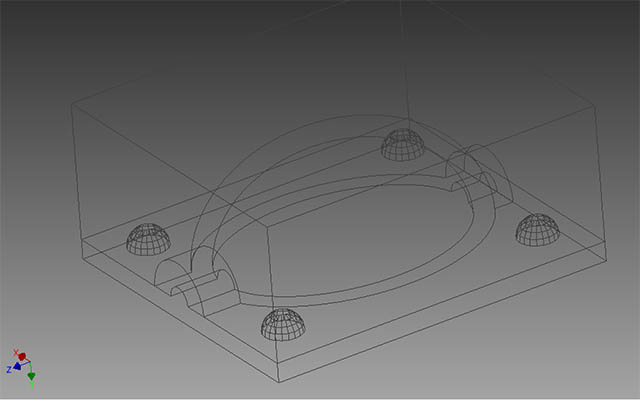

The arm parts what I modified were too thick to bend it by hand. It is too hard to bend it. so I had to redesign the design files. I read design rules for softrobotics on the website.

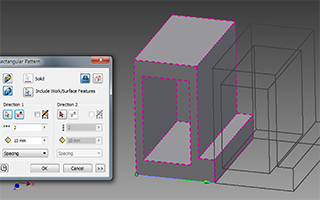

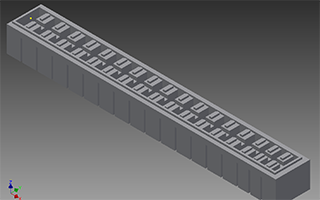

Rectangular Pattern - make chambers |

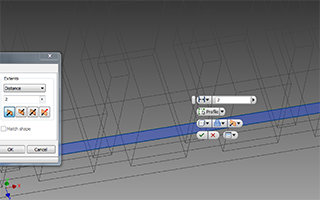

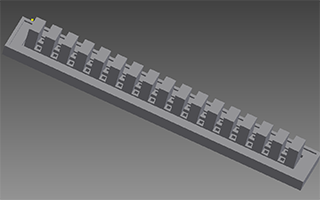

Making air holes |

Model completed |

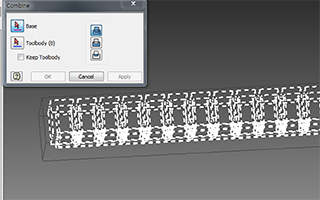

Combine - make molds from the model Combine - make molds from the model |

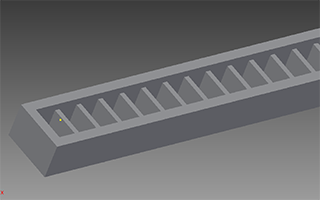

mold top |

mold bottom |

Bottom layer mold |

|

|

|

Failure

I designed two thin layer (1mm thickness) so it was too easy to be torn. I redesigned to 1.5mm thickness. It was fine.

|

|

Complete!