3. Computer Controlled cutting

build press-fit constructions

download files (ipt, dwg, dxf)

Playing with A Vinyl Cutter - making stickers

I made stickers using Adobe illustrator, Vinyl cutter(Silhoutte Cameo) I learned from the tutorial on link below

https://www.youtube.com/watch?v=HkuMvSpKaKc

-

import vector file : Iused a logo of Digital Hippy that represents my life style:)

-

make a new layer and name it “cut path”

-

copy the design on new layer

-

un-gruping them all, make a clipping mask (command + 8)

-

make offsets (object - path - offset) : I build offsets 5mm, rounded corner.

-

make offsets one more time (for making corner more rounded) : I set it for -2mm

-

export to dxf file (only a cutpath layer)

-

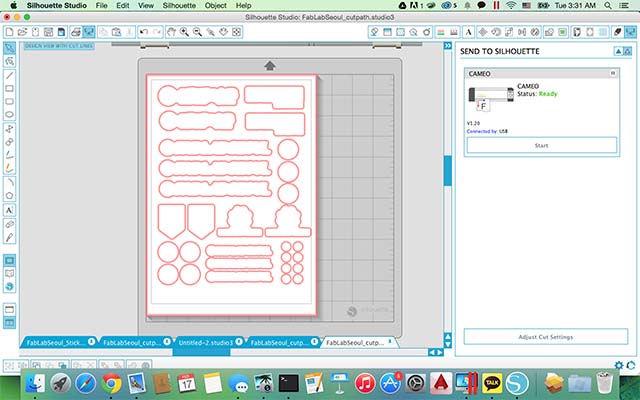

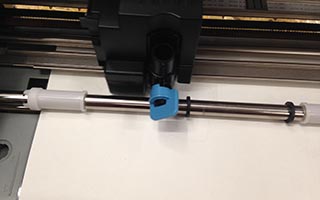

Download Silhouette Studio (Print driver). Fab Lab Seoul has a small vinyl cutter (Silhouette Cameo) This machine’s cutting size is A3.

http://www.silhouetteamerica.com/software -

I used the Formtec Inkjet label papers and adhesive sheets for its cover. I printed my design on the label papers with HP officejet Pro 8600. And I glued down the adhesive sheets on the papers.

-

Open the dxf file with the Silhouette Studio. check media size to A4

-

check the depth of the knife. sometimes it cannot cut through the label paper

-

Load media, press the start button.

Calibration problem Offset cutting Using Vinyl cutter

Calibrate position of the paper Adjust the depth of cutting

Print with normal Paper Calibration success

Fabmodule

I tried Fabmodule to make outlines (png to svg). It was very simple.

-

go http://fabmodules.org/ and import PNG file

-

set the output to vector file (SVG), choose outline, and save the output file

Press-fit construction

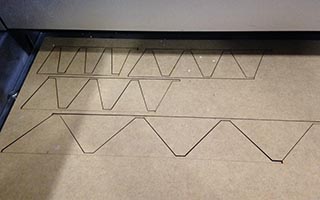

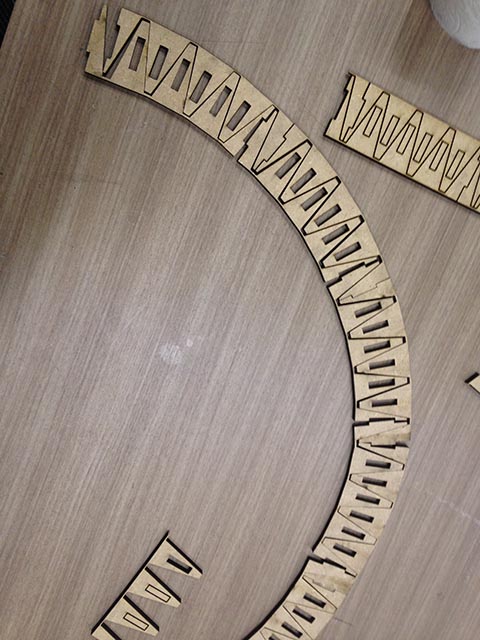

I thought about a mechanism of zipper. because It’s an amazing press-fit method. I found a awesome way to make furniture called ‘zipchaise’ using innovative method of bending wood panels without using molds. I wanted to make 3D press-fit kits from the this kind of mechanism. if we cut patterns on mdf, we could only bend vertically to plane. It can bend wood parallel to plane, so we can save a lot of materials than using other methods like 123D make.

http://www.contemporist.com/2008/08/26/the-zipchaise-by-schindlersalmeron/

Parametric design

-

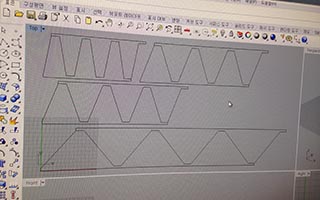

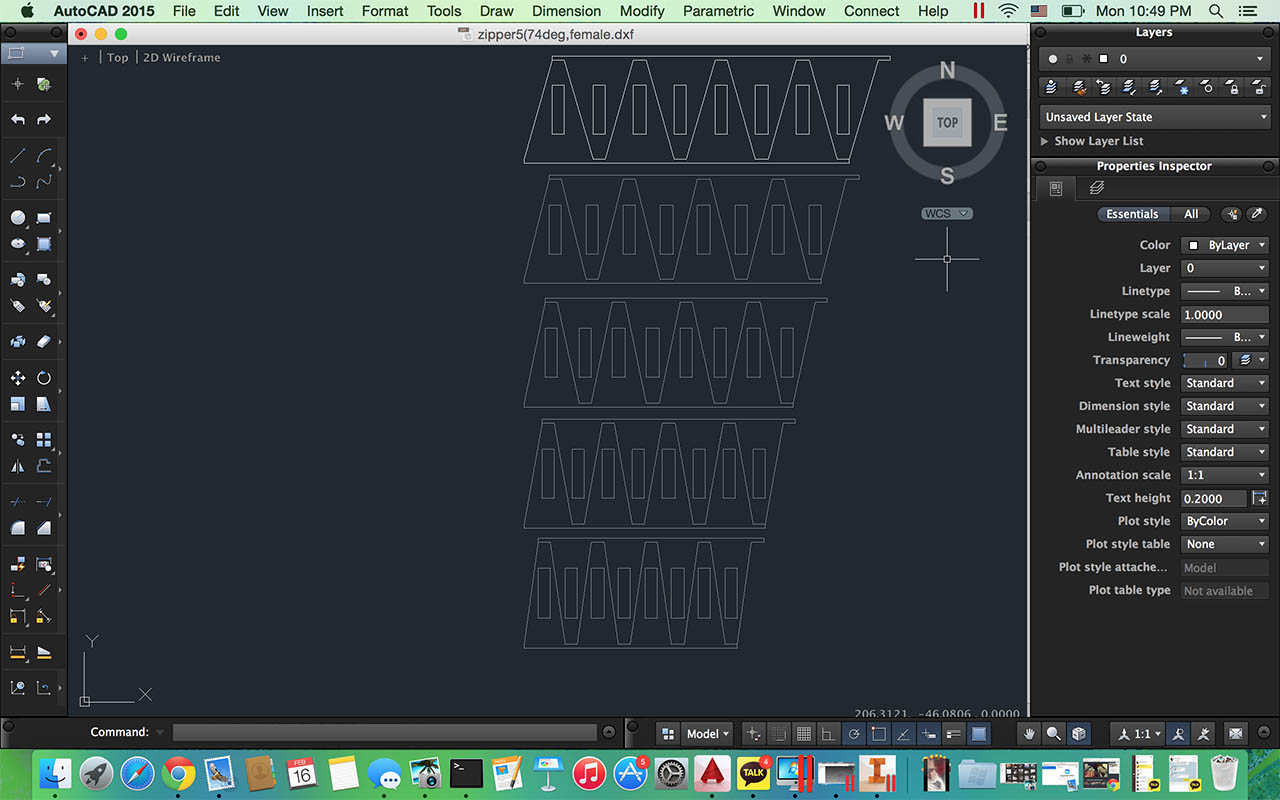

For testing with the different angles, I used parametric design by not only Autodesk Inventor, but also I tried with Antimony, Rhino, and Auto CAD, but it was not easy for me to complete this project on time. so I used the tool that was more familiar to me.

-

for test bending, I made 10 defferent angles. I used 6mm mdf. I found that 74deg and 80deg are bended well.

Parametric design tool is easy to change parameters for test with variable values |

I also first used Rhino CAD program with beta version for mac |

each angles are litte different |

|

Conclusion

It was not easy to make 3D press-fit construction, but I found that zipper mechanism I can bedespress-fit construction. It stay with inner force from each others.

Failures

3mm is too thin to making press-fit. that is easy to brake.

I made Common mistake, I didn’t check the MDF is cut completely before take out from laser cutter.

ReFerences

-

Press-Fit Construction Tips (Fab academy)

http://fabacademy.org/archives/content/tutorials/04_Computer-Controlled_Cutting/Press-Fit_Construction_Tips.html -

Bending any shapes

http://www.thingiverse.com/thing:109492/#instructions -

Silhouette Studio Download

http://www.silhouetteamerica.com/software -

Silhouette CAMEO cut direct from Adobe Illustrator a decal

https://www.youtube.com/watch?v=ND13d7r285s