1. Vimeo Links : One, Two

2. Assignment: Uncreative, just make the Fab ISP.

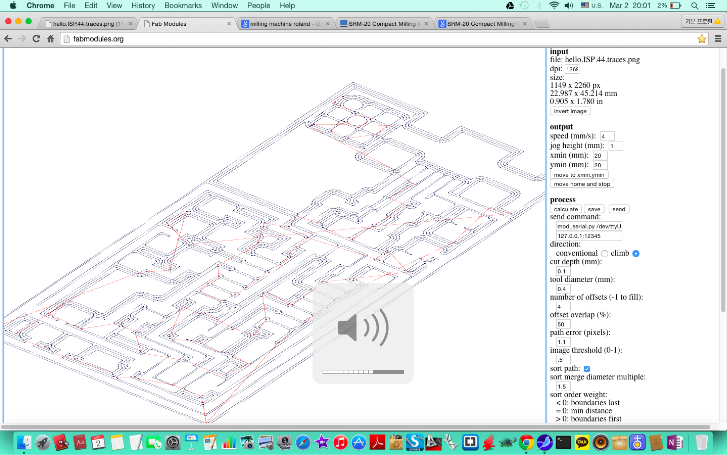

A. Downloaded the PNG file and used Fab Modules online. (http://fabmodules.org/)

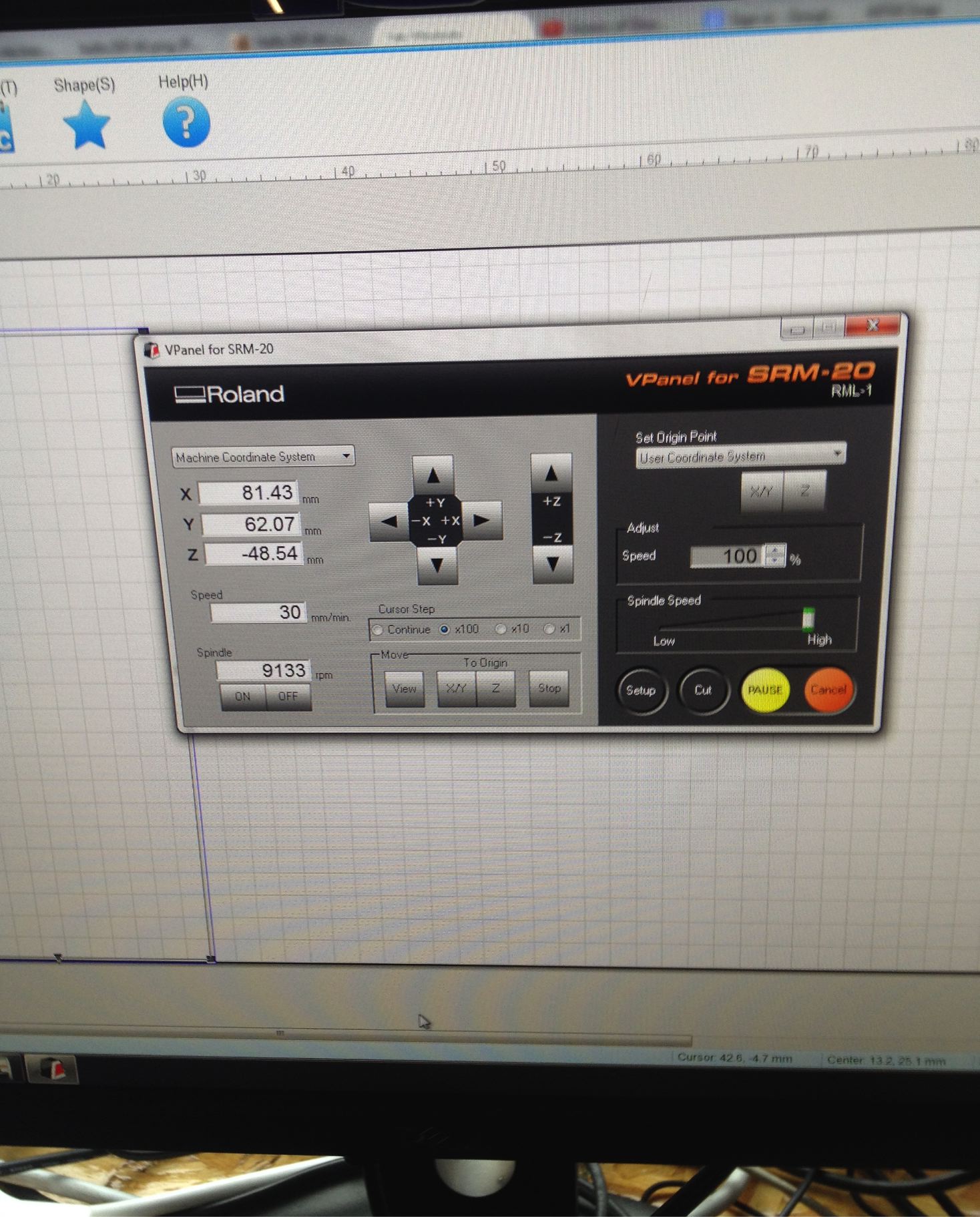

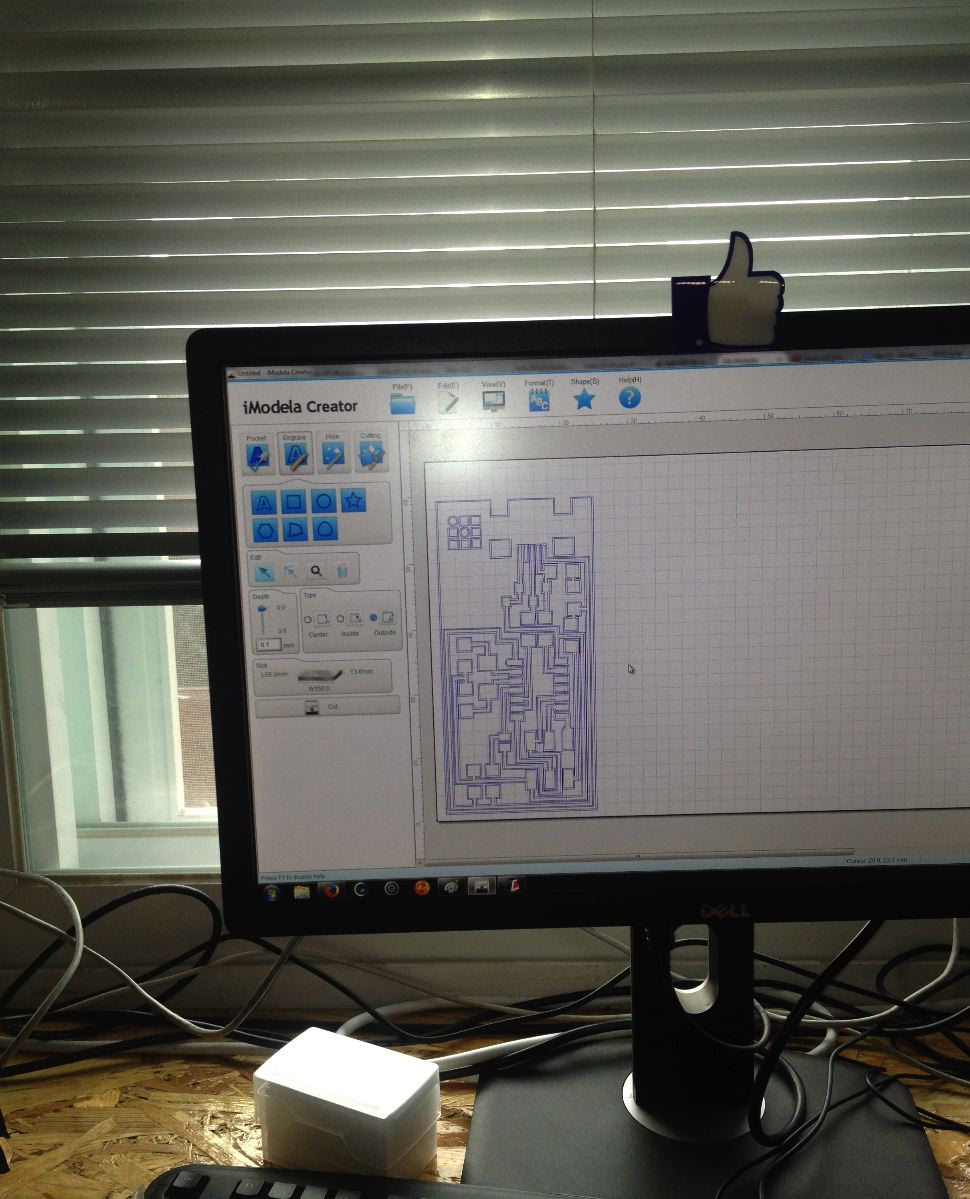

B. Because the machine(Roland SRM-20) at the fab lab Seoul had its own software,

I used the numbers calculated from the fabmodules online.

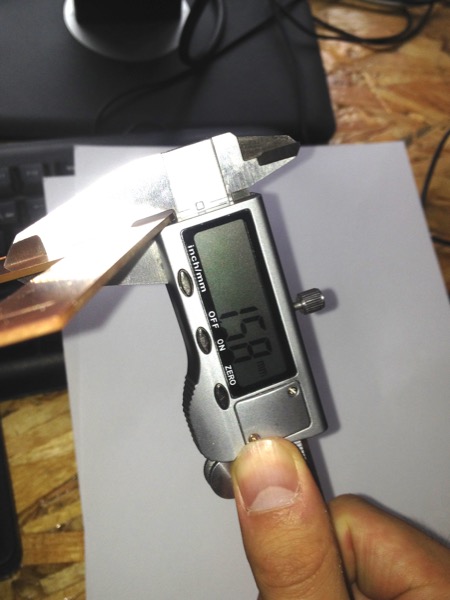

C. Before milling, the thickness of the board was mesured by the calliper. It was around 1.58mm.

The thickness was set to 1.8mm.

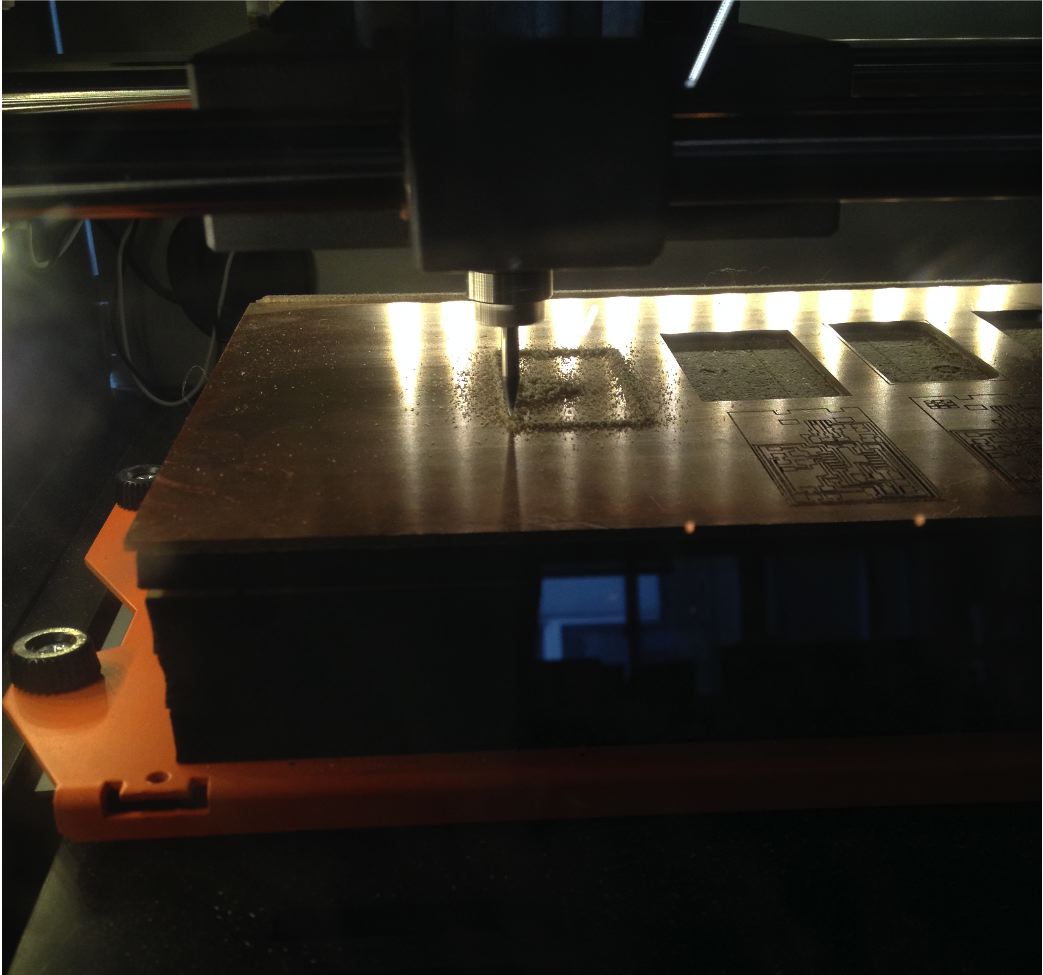

D. The 1/64 was used to trace the circuit and 1/32 CNC milling cutter was used for the outside trace.

The speed was 4mm/sec for the old cutter and 3mm/sec for the new cutter.

Since the cutter was the new at the Fab Lab, I made it to 3mm/sec which was converted to the

roland software 180mm/min.

E. Before cutting the cutter and the board were fixed to the milling machine.

The cutter is weak and easily broken, it was handled with care.

First, the cutter was inserted to the collet at the maximum. After setting up the origin (X,Y,Z)

the cutter is released to the surface as the board is pressed by the hands.

F. The board was cut.(The Roland SRM-20 did not offered the multiple number of offsets.)

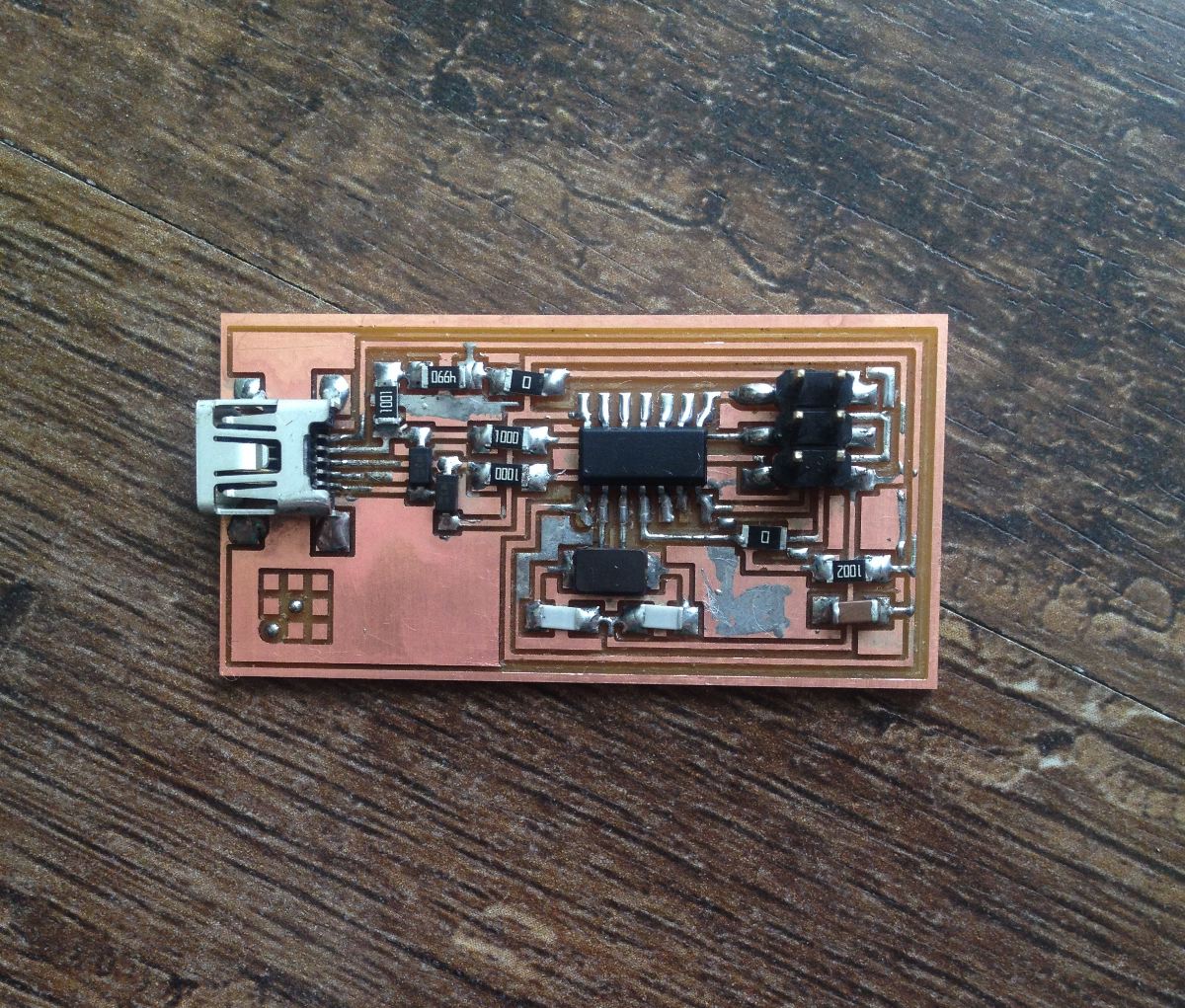

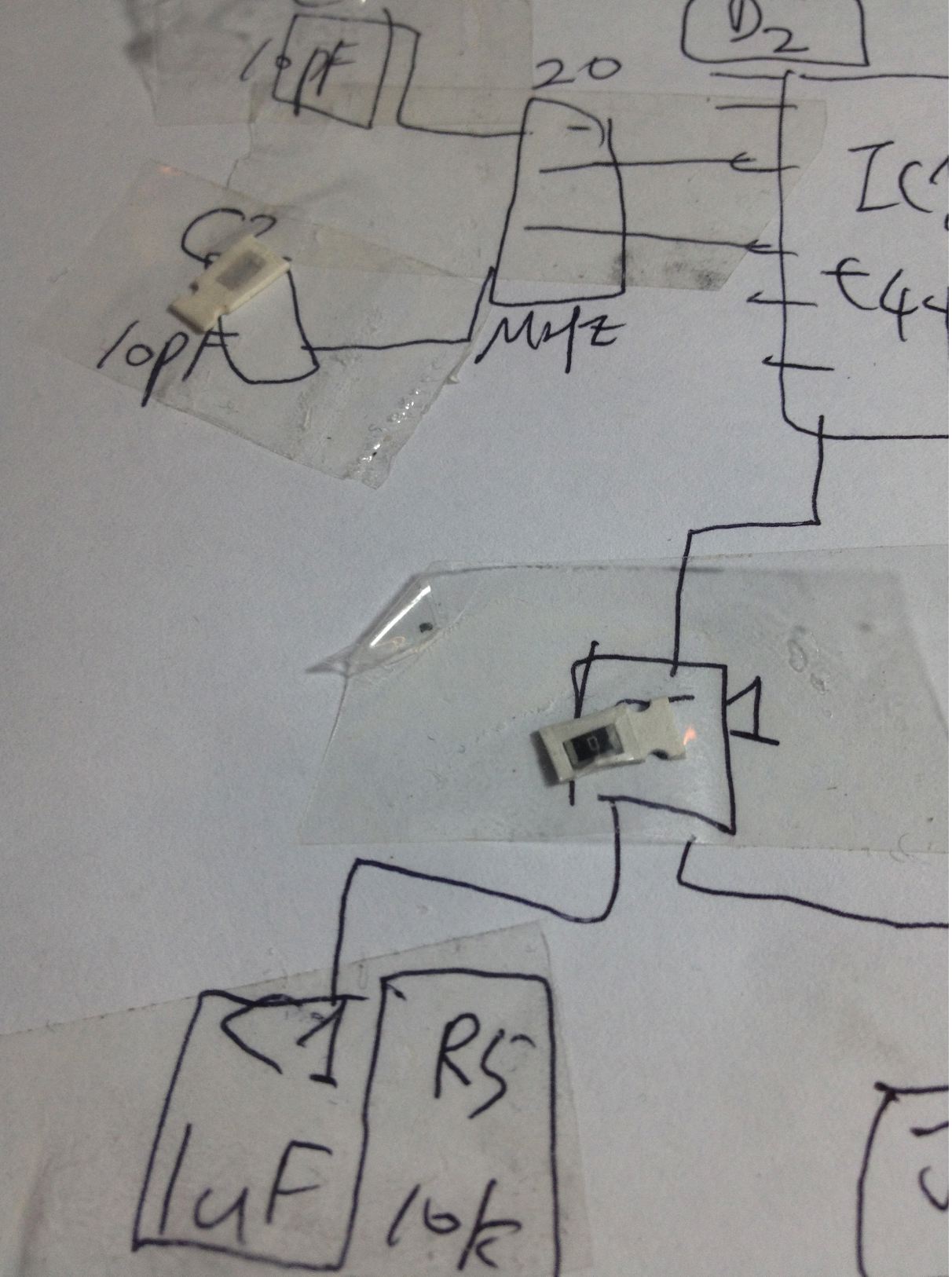

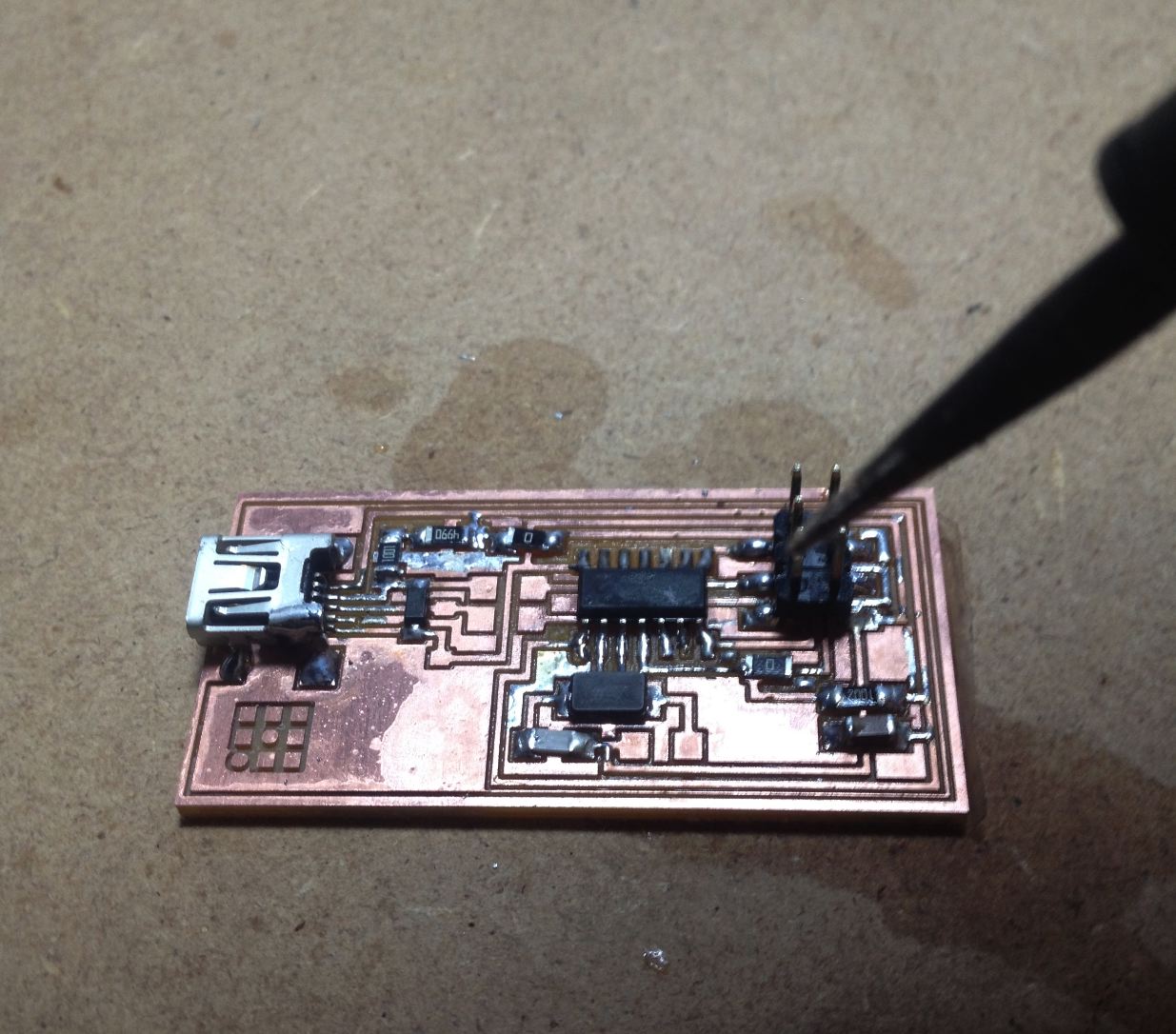

F. The capaciter, resister, microcontrollers were placed on The breif sketch with tape.

G. The soldering was done with lots of flux. (Needed to be shiny!)

H. Finally it was done and tested by plugging into the computer to see of it breaks.

I. It was successfully soldered!!! (It was cleaned with alcohol to prevent staining)