1. Vimeo Links : One, Two

2. Assignments : Design and Make a 3D mold (~ft2), and Produce a Fiber Composite Part in it.

3. Tryouts

A. For this week, I made a longboard deck.

So the steps are:

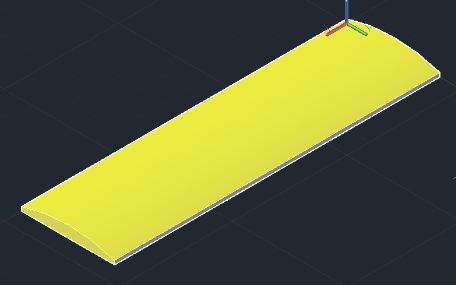

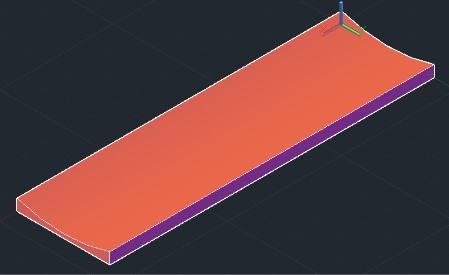

1) Make the 3D model of the deck and mold.

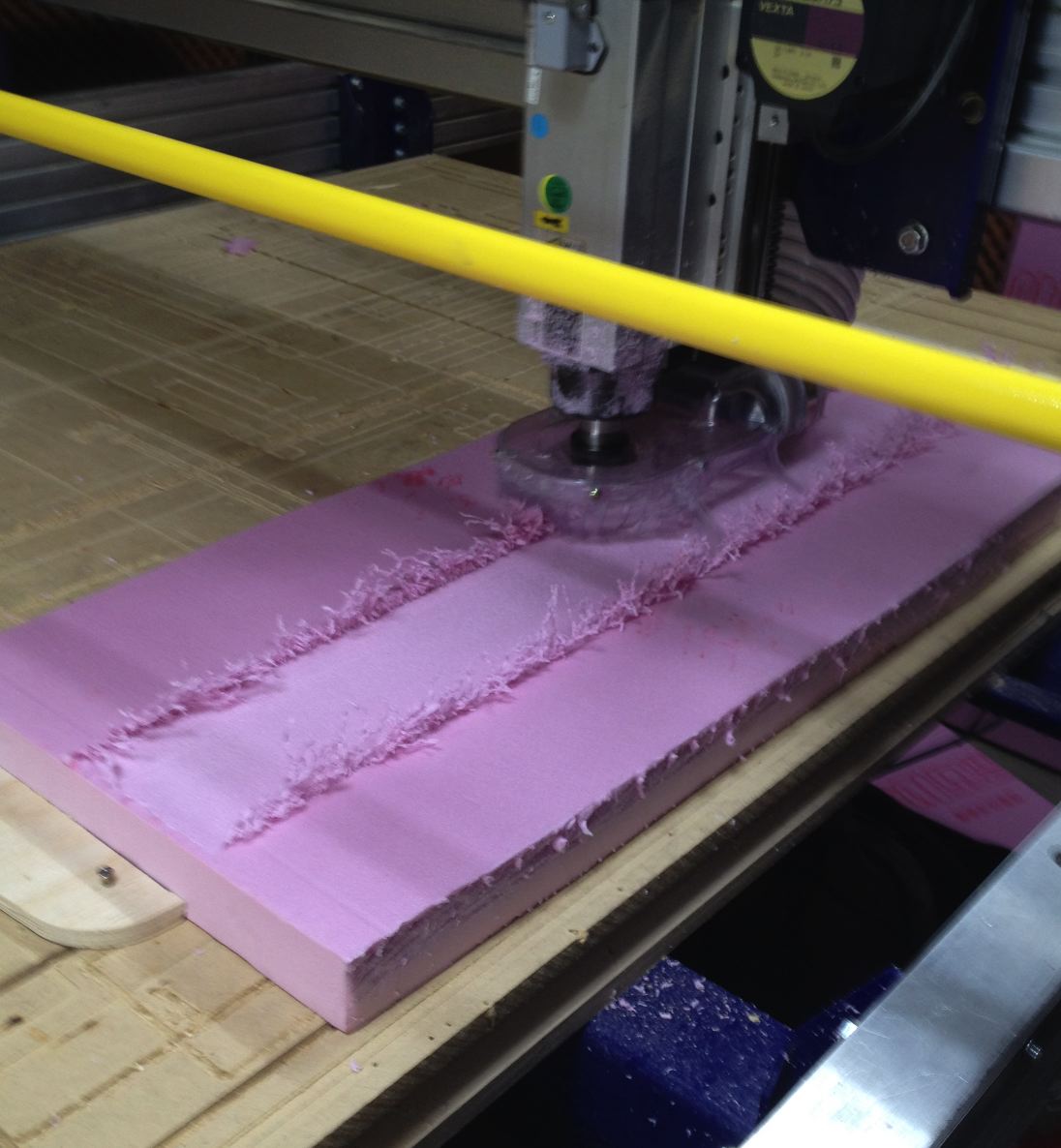

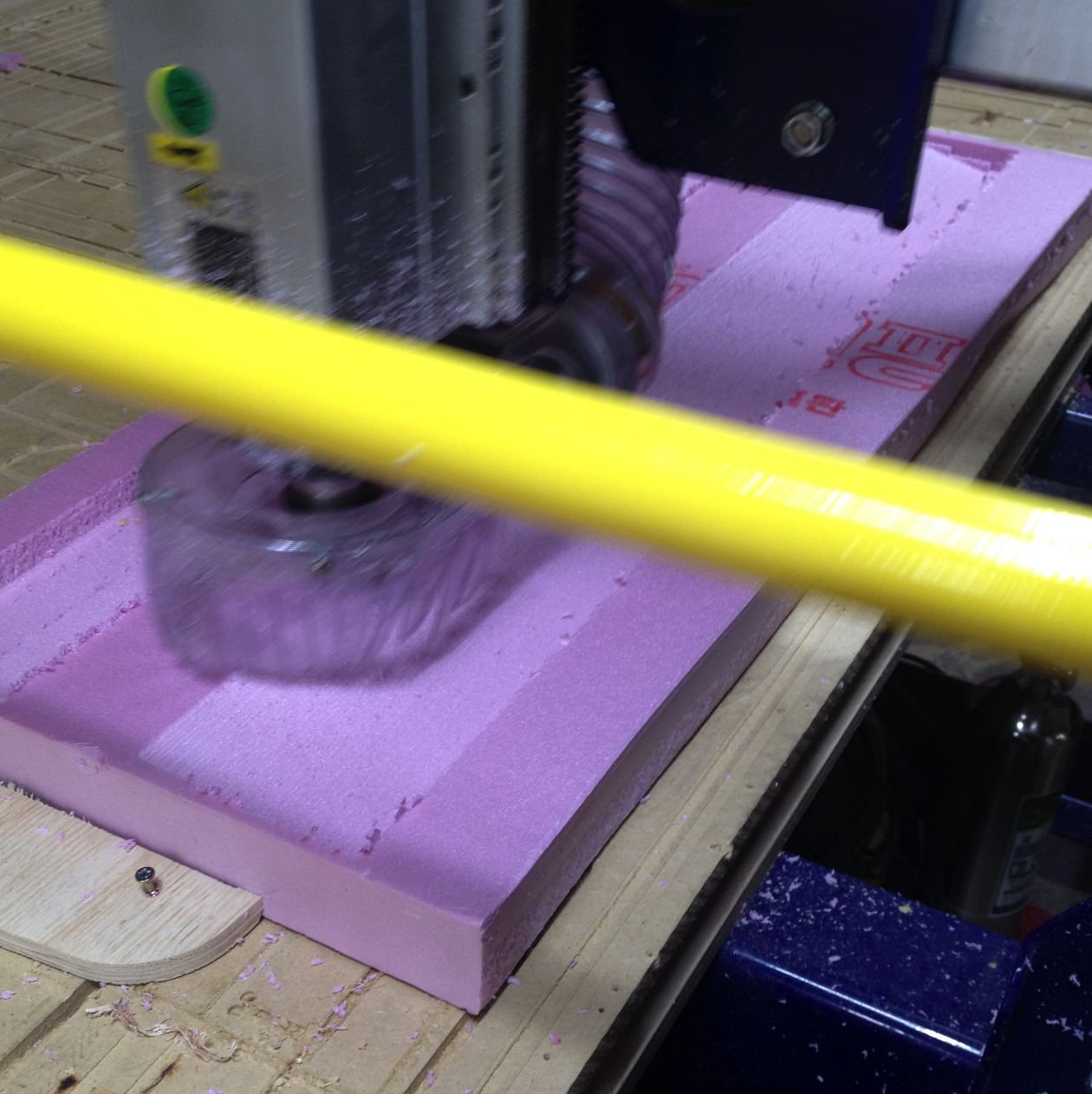

2) Cut the mold with the shopbot.

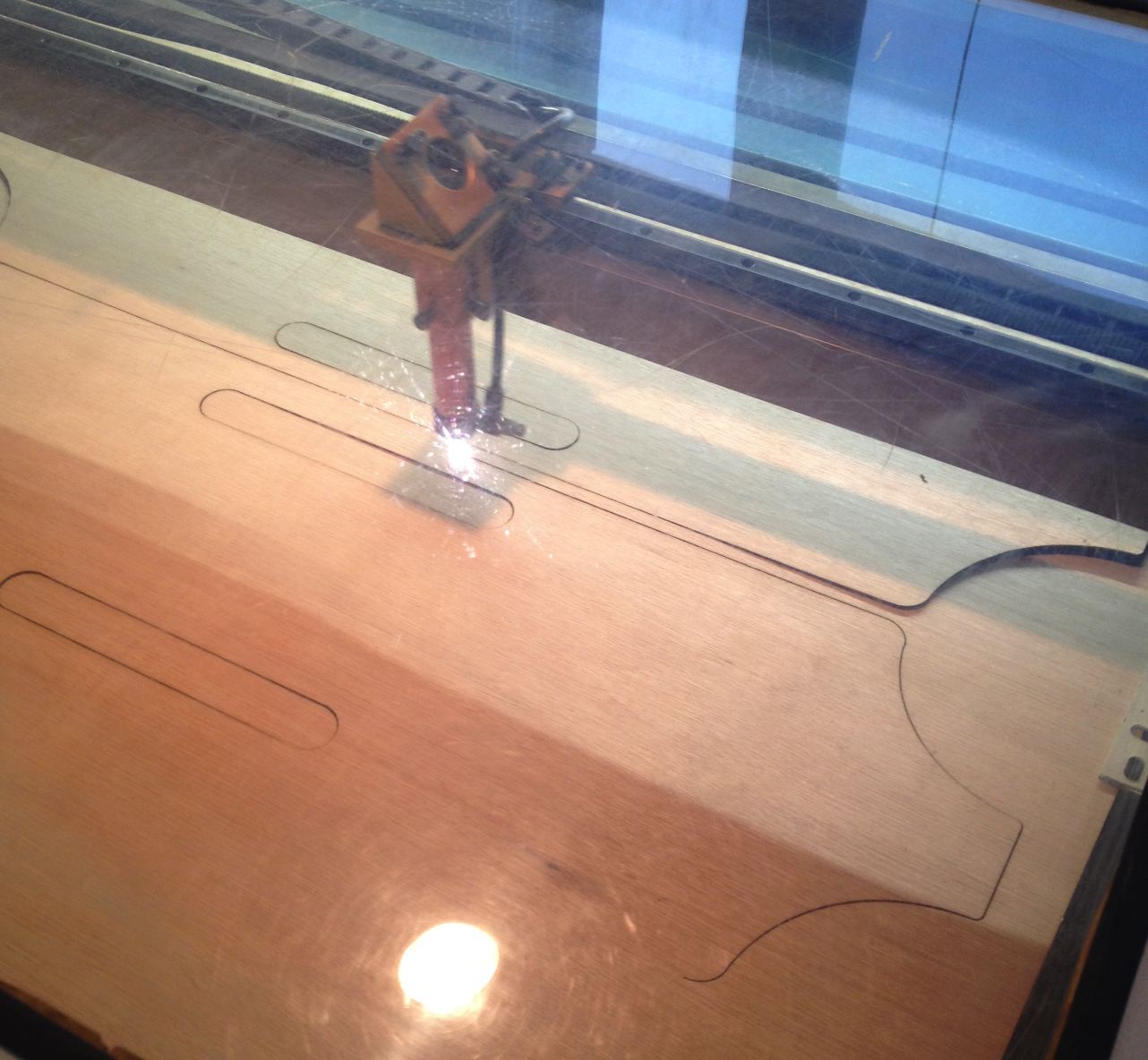

3) Cut the wood layer and fiber composite by laser cutter.

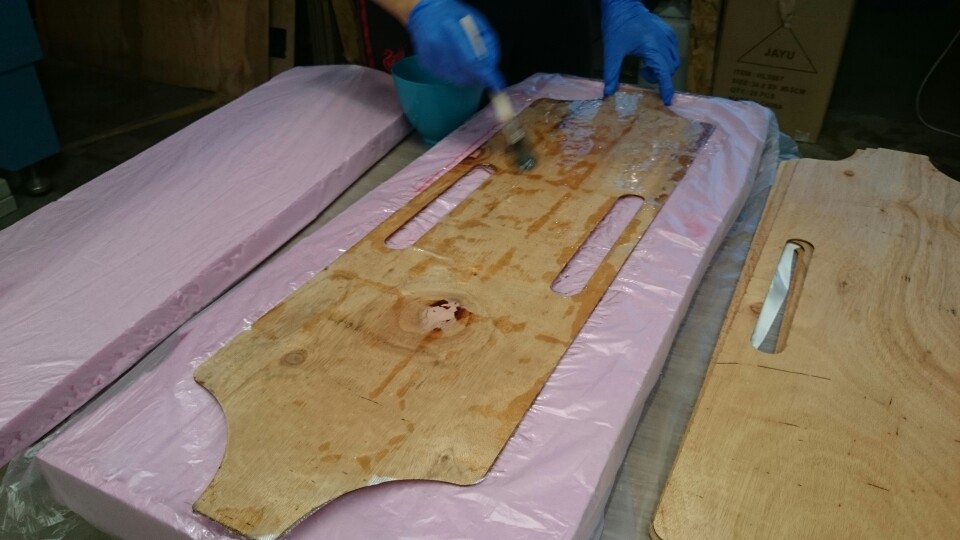

4) Layer woods and fibers as applying policoat epoxy.

5) Compress the layers with the mold.

B. Tryouts (MOLD)

1) I drew the mold with the Autocad.

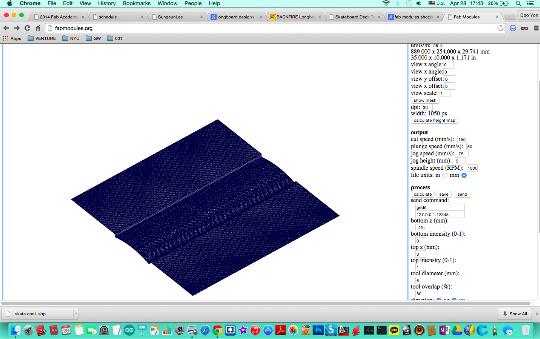

2) I used the fabmodules.org to convert to shopbot file.

ROUGH CUT

- units/in: [25.4]

889.000 x 254.000 x 30.571 mm

35.000 x 10.000 x 1.204 in

- dpi: [10]

- file units: in() mm(O)

- cut depth (mm): [6]

- tool diameter (mm): [6]

FINISH CUT

- units/in: [25.4]

889.000 x 254.000 x 30.571 mm

35.000 x 10.000 x 1.204 in

- dpi: [10]

- file units: in() mm(O)

- cut depth (mm): [6]

- tool diameter (mm): [6]

- tool overlap (%): [80]

- direction: (O) xz (O)yz

- type: (_) flat end (O)ball end

* Note: if the overlap is 80%, the direction does not need to be XZ and YZ.

Choose either XY or YZ. I stopped the machine after one direction for time.

3) However, the result was not good as it looks, so I used the Photoshop PNG files.

4) I used the gradient tool to make PNG file. For the fabmodules, only number necessary for PNG is the bottom z (mm): [30]

C. Tryouts (FIBER COMPOSITE)

1) I checked the thicknes of the skateboard. It was around 10.32 and the wood fiber was 1.84.

So I laser-cut 4 layers of the wood fiber and 2 of polyester fiber. For cutting take a look at the wood fiber and try to cut vertically.

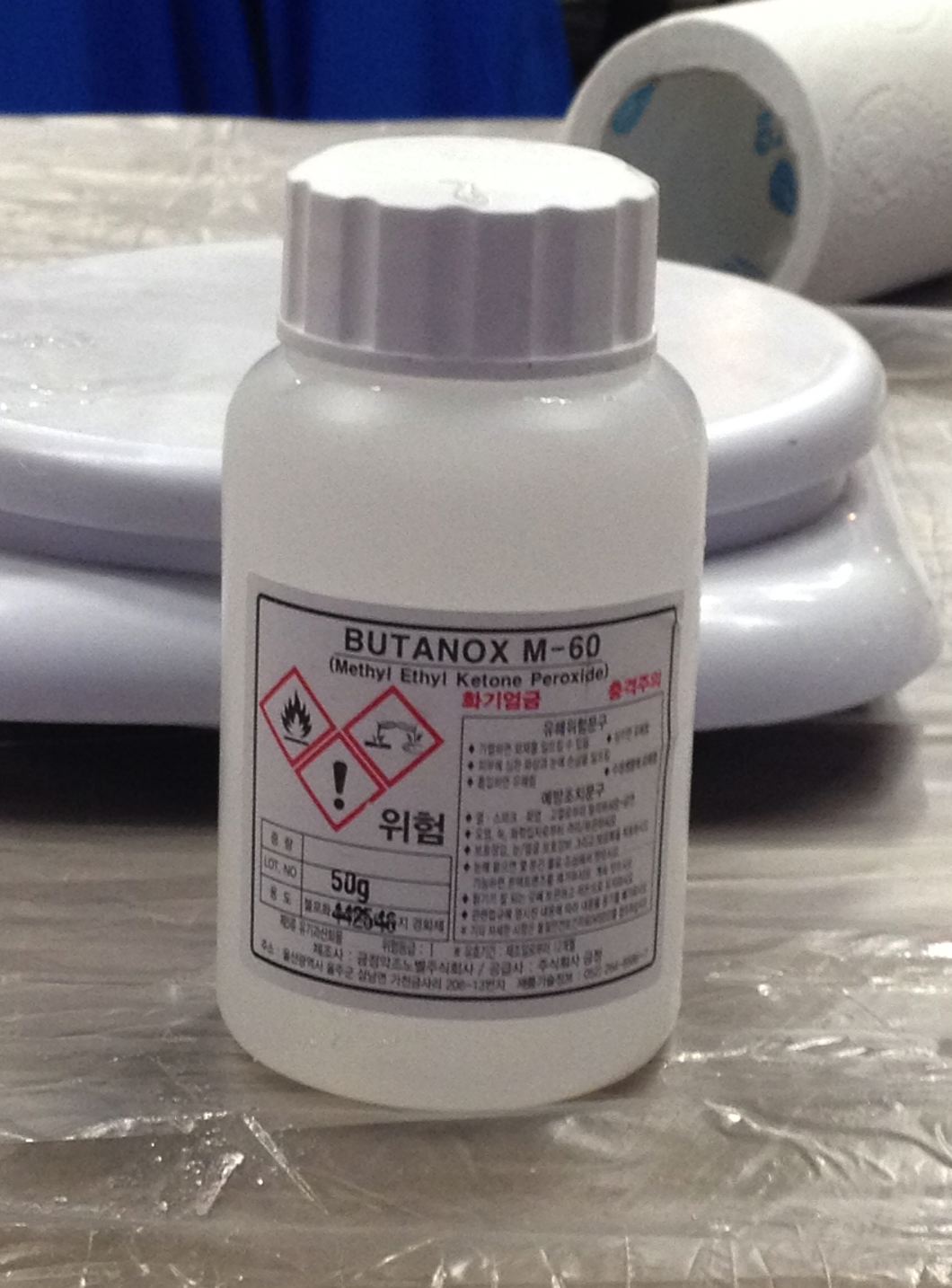

2) I used polycoat and catalyst. The ratio is 100:1.

3) I mixed it well and layered the pieces after applying chemicals with the brush.

After stacking layers, place the top mold and compress it with weight.

D. Result