Fab Academy 2015, Dong-Hyun Kim

Molding and Casting

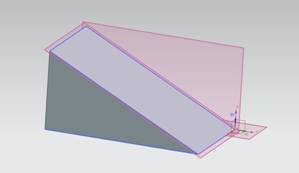

Molding Design (For CNC Router)

Making mold for making wax

http://boxmaker.connectionlab.org/

http://www.makercase.com/

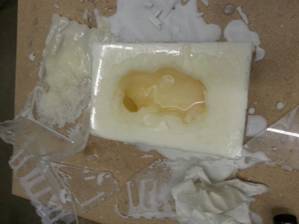

Making Wax

Machining

Silicon casting

Finish

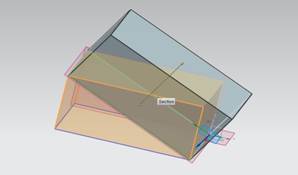

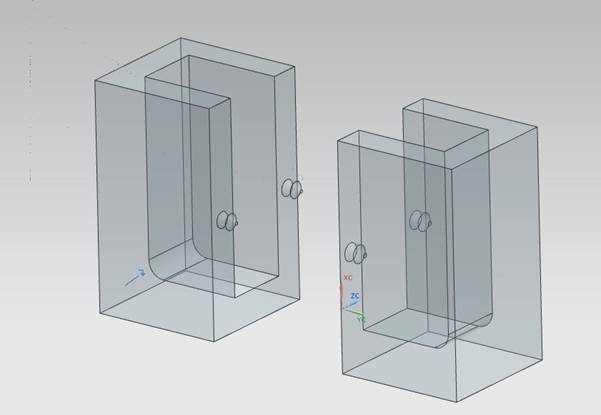

Molding Design (For 3D Printer)

Separate two piece of molds for separating easily. One is male, another one is female, so they can assemble exactly.

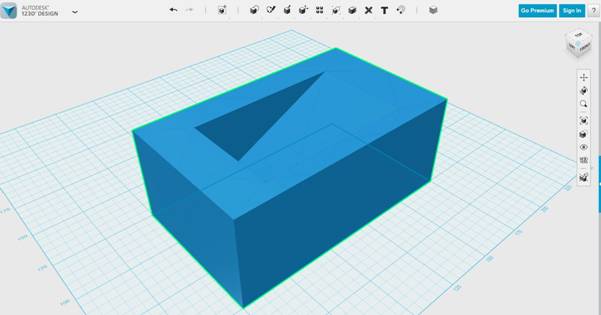

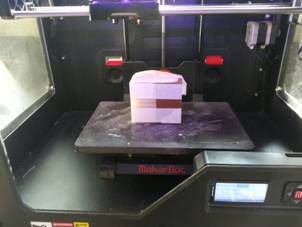

Fabricate with 3D Printer

Fabricate mold with 3d printer

Casting

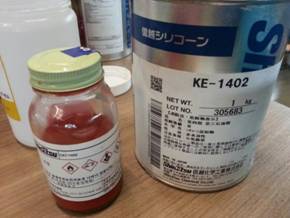

Preparation

- Electronic scale

- Bowl

- Stick

- Silicone

- Hardener

In case of bowl, preparing rubber bowl is better than plastic or steel bowl, because when you done your work, you can get rid of rest material easily.

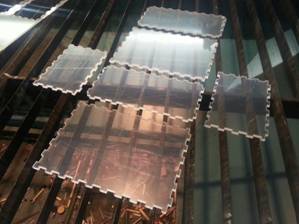

For making ‘fabkit’ housing that will be plant my final project ‘Open bicycle’, I did casting a board.

The most important thing, for mixing with silicone and hardener, is the ratio of amount of hardener.

It depends on the material supplier, so you have to check the ratio of material.

When you put in hardener, you have to mix as soon as possible.

When I do casting, I used ‘KE-1402’ from Japan, ShinEtsu Company. Their hardener ratio is 10:1 (Silicone:Hardener).

For accuracy, I measured an amount of silicon and hardener with electric scale. And then mixed with stick.

The second important thing is vapor, When you do casting you have to put the silicone to mould as thin as possible.

If you have an oven, you can shorten harden time. But we don’t have oven in Fab Lab Seoul, So I used 3D Printer’s heating bed.

TIPS

- When you do casting you have to put the silicone to mould as thin as possible.

- If you use oven, you can shorten harden time.

Download files

Mold 3D CAD