Fab Academy 2015, Dong-Hyun Kim

Computer-controlled machining

Make something big

Design

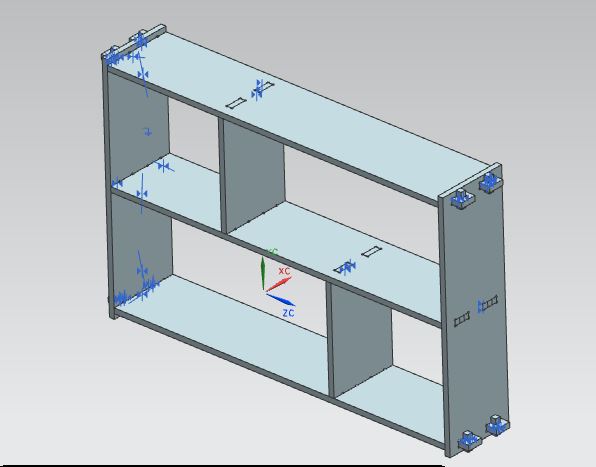

Using UG-NX(3D CAD Modelling Tool), I drew 3D CAD and do assemble it. As a following picture, simple structures are press-fitted.

It is very important that Each sheets are press-fitted. What happen, If there no cautions about the edge of sheets, Operate CNC machine?

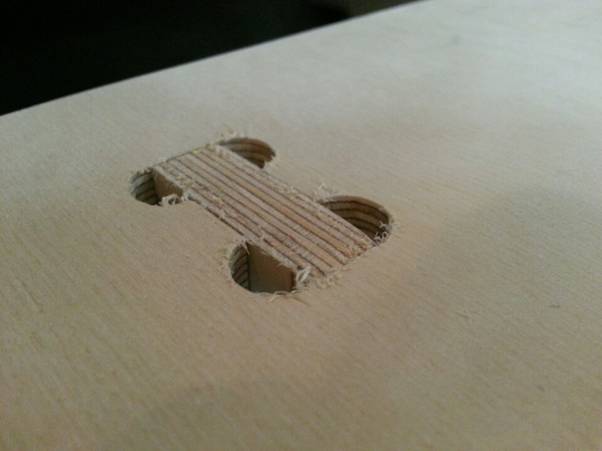

Exactly, there are some problems. Because why ‘End mill’ has a circular shape, So if you just do anything and run a CNC machine, you cannot press-fit your wooden sheets.

To solving kind of this problem, you have to think and redesignCAD modeling to making space for end mill can be through the hole.

Fabricate

We use Shopbot CNC.

Using ‘Asphire’ an exclusive software for Shopbot tools, we can 2D cut easily.

CNC tooling process

- Drawing 2D CAD Model

- Selecting each paths

- Selecting a type of mill

- Selecting an origin point

- Tooling

There are some difference between 3D Printer and CNC machining.

3D Printer is an additive manufacturing and CNC is a subtractive manufacturing.

Because of feature of manufacturing method, It cuase lots of dust and trash, So we have to always clean up.

When spindle on CNC Router was broken, it such as a bullet, So, when you want to use machine, you have to put on safety harness like goggle and ear muffs. And always operator have to be near machine.

Many guys have a mistake material thickness, It cause when you fabricate with using a rough surface materials.

If you are not certain, you cannot cut what you exactly want thickness. To solve this problem, you have to check thickness at each edge and compare each other, then cut more thick than what you measure the most thick one.

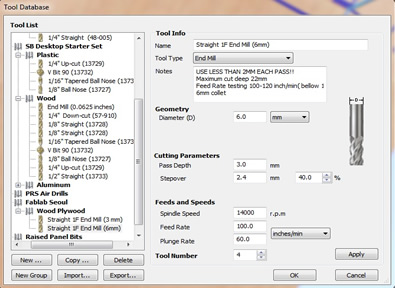

Parameter

- Diameter : 6.0mm

- Pass Depth : 3.0mm

- Spindle Speed : 14000rpm

- Feed Rate : 100.0

- Plunge Rate : 60.0

- Material : Plywood 12T

Assembly

It is very important before when you cut whole parts, cut small parts and check tolerance. When you check it okay, put in your whole CAD file and fabricate it.

There is no need to use glue for press-fit. Modify Tolerance and then assemble using rubber hammer.

Finish !

TIPS

- Usually you will cut plywood with using 6pi end-mill. When you use 6pi end-mill, you have to set 3mm cut depth(this is the half of end-mill’s pi), 14000rpm, and 10mm/s cut speed.

- When you measure four edge of material thickness and put in the thickness of the most thick number, then you can cut perfectly.

Download files