Computer-controled cutting

Laser Cutter

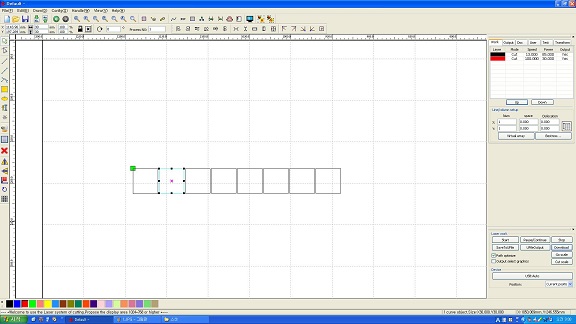

This is the Laser cut 4.5 program's interface that we use in Fab Lab Seoul. With this program we can easily draw polygons and edit layers, do engraving and even cutting. But, accuracy and other user interface is very poor so it's only used for seperate-layered cutting.

Looking at the right control panel it's showing 'layer setting' and when doing dividing the layer we are supposed to set the bottom palette first.

There are things to be considered adjusting the settings. when selecting the layers the colors are reversed so it's important to check again whether the layers

are selected or not. To sum up, it's all about checking the layers again to reduce mistakes.

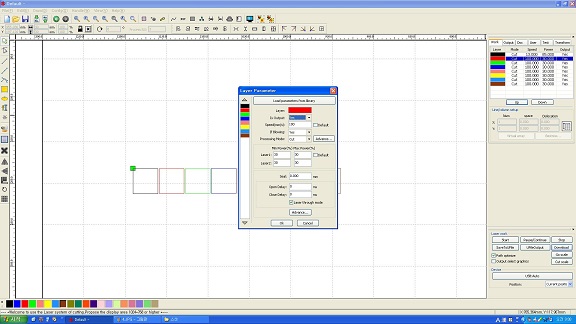

We can set whether the layers would be cut or engraved and set the power and speed. It can be easily changed with number keypads with user's taste.

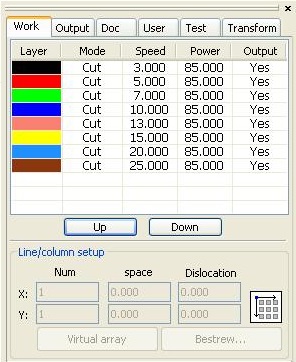

To cut 6T MDF cutting, we have to fix the power and change the speed to check whether the rectangle is cut clean. I've tested lots of different variables to check the numbers.

.jpg)

.jpg)

Using calipers i've checked the exact thickness of my wanted material and fixed the 'power' variable and tried different speeds.

.jpg)

To compare the results more accurately, I've used calipers many times.

1. Speed : 03.00, Power : 85.00, 29.00mm (30.00mm)

2. Speed : 05.00, Power : 85.00, 29.25mm (30.00mm)

3. Speed : 07.00, Power : 85.00, 29.50mm (30.00mm)

4. Speed : 10.00, Power : 85.00, 29.60mm (30.00mm)

5. Speed : 13.00, Power : 85.00, 29.70mm (30.00mm)

6. Speed : 15.00, Power : 85.00, 29.70mm (30.00mm)

7. Speed : 20.00, Power : 85.00, 29.90mm (30.00mm)

8. Speed : 25.00, Power : 85.00, x (30.00mm)

.jpg)

7th and 8th trial didn't cut well with the numbers

next trial was changing the power with fixed speed

1. Speed : 10.00, Power : 85.00, 29.65mm (30.00mm)

2. Speed : 10.00, Power : 80.00, 29.65mm (30.00mm)

3. Speed : 10.00, Power : 75.00, 29.65mm (30.00mm)

4. Speed : 10.00, Power : 70.00, 29.60mm (30.00mm)

5. Speed : 10.00, Power : 65.00, 29.60mm (30.00mm)

6. Speed : 10.00, Power : 60.00, 29.60mm (30.00mm)

7. Speed : 10.00, Power : 55.00, 29.60mm (30.00mm)

8. Speed : 10.00, Power : 50.00, 29.60mm (30.00mm)

Compare to the prior text there weren't much of a difference this time.

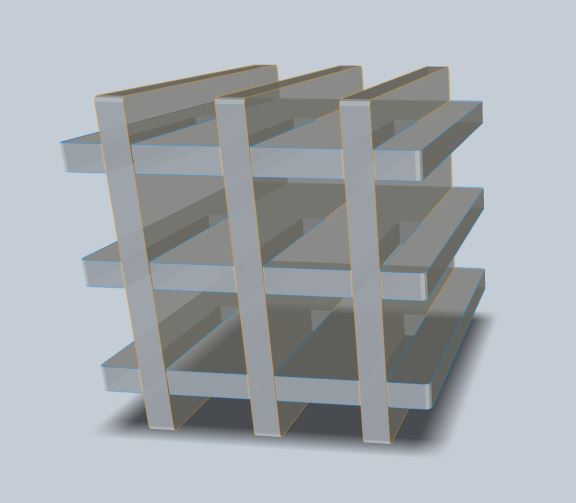

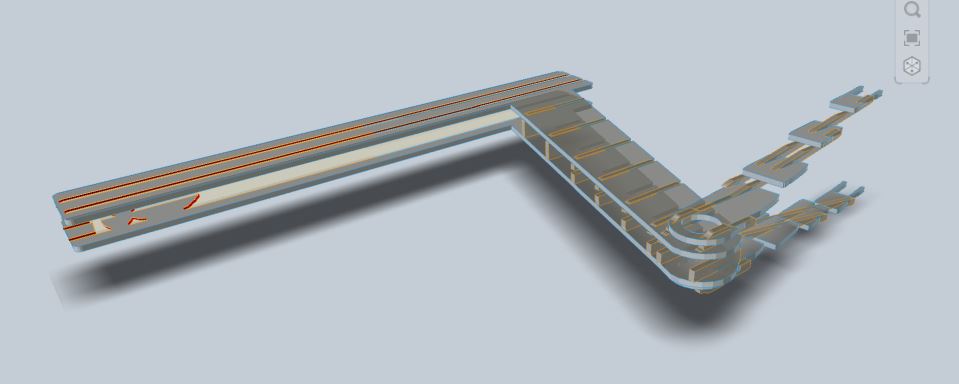

Next, I used Autodesk 123D Make program to try the concept 'Press-fit' I've created a cube to check the sample. I've used the same material i used with the testing and fixed the thickness (6T)

With setting above, I've referenced my own work to pressfit my final project and prototyped as a MDF material.

.jpg)

Using UG-NX 7.5 I've modeled my final project and exported to stl. However, i've found some missing space when loaded with

123D Make file. later on, I'm going to use different tools to cure the problem.

Setting the material as shown, and tried the press-fit.

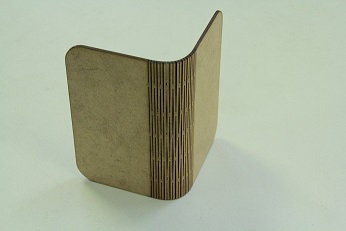

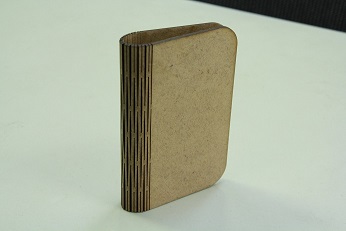

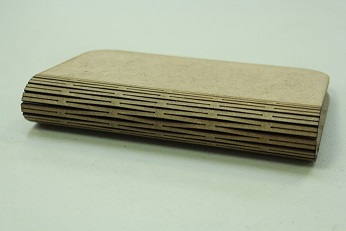

To bend the MDF i've inserted a pattern and made pocket note holder.

.jpg)

.jpg)

.jpg)

Drawing with Rhino

.JPG)

.JPG)

.JPG)

.JPG)

Vinyl Cutter

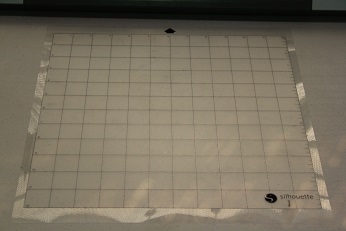

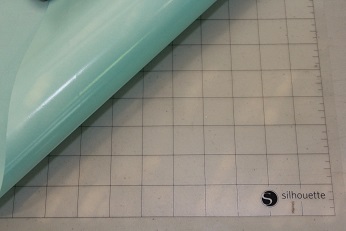

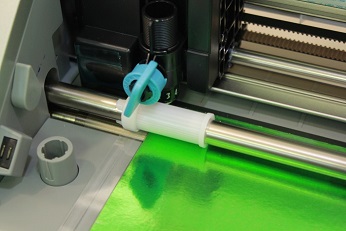

Vinyl cutter that i used was 'Silhouette Cameo'. Basically it's equipped with cutting pad in sticker type and with this cutting pads i can glue down the material. To fix the maintenance all we have to is remove the vinyl and use the machine.

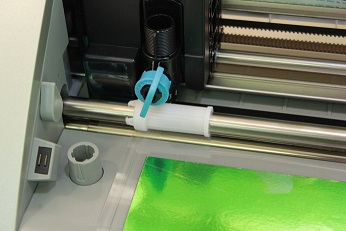

Adjusting the height of cutter by the thickness of paper is the key to using the vinyl cutter. That's why i manually check the cutting module

and check if it's suitable for the wanted paper.

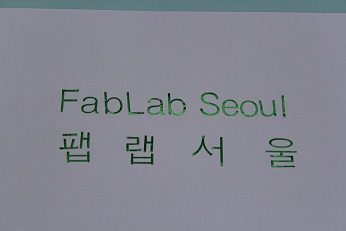

Ta da! I've created Fab Lab Seoul sticker!!

Download files

Pocket Note Holder

Fab Lab Seoul Font

Vinyl cutter that i used was 'Silhouette Cameo'. Basically it's equipped with cutting pad in sticker type and with this cutting pads i can glue down the material. To fix the maintenance all we have to is remove the vinyl and use the machine.

Adjusting the height of cutter by the thickness of paper is the key to using the vinyl cutter. That's why i manually check the cutting module and check if it's suitable for the wanted paper.

Ta da! I've created Fab Lab Seoul sticker!!

Download files

Pocket Note Holder

Fab Lab Seoul Font