Fab Academy 2015, Dong-Hyun Kim

Mechanical design, machine design

Make stage

For making a machine, we consider that modifying MTM(modular machines that make).

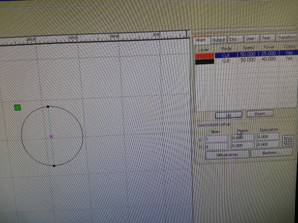

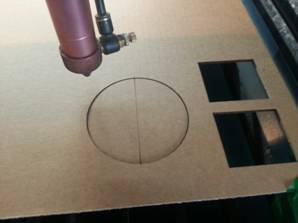

First of all, I just checked laser’s power and speed. Because MCM is made with card board and it need to two kind of cutting method like cut and engrave(just half cutting for bending).

Cut [Speed : 50, Power : 25]

Half cut [Speed : 50, Power : 25]

Machine : LaserPix Xcut1390

Material : Cardboard 3T

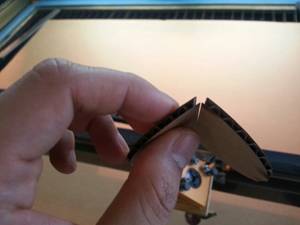

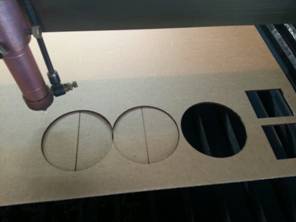

Bend a cardboard and glue it, and assemble a stage.

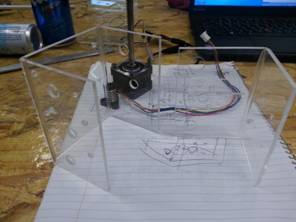

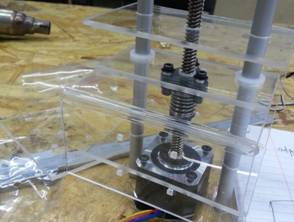

Z axis pen holder part

For the making additional part(Pen holder), I design that part for acryl bending structure.

The difference between cardboard and acrylic was obvious we could squeeze in the bearing but acrylic doesn’t, therefore giving it a tolerance test was needed to fit the circle hole. Stepper motor was then assembled and we intend to make the movement only between acrylic barriers. Which is way more than we need for holding a pen and lowering the z-axis for actual drawing.

Redesign a hole for tolerance.

Make 3D structure with 2D acryl bending. So I made structure that spending less material.

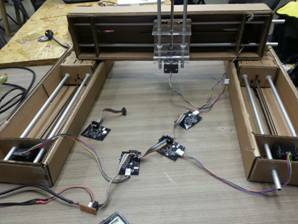

Complete a machine building.