12 -

Composites

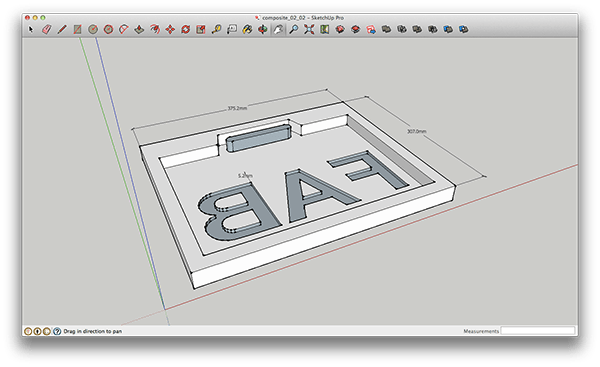

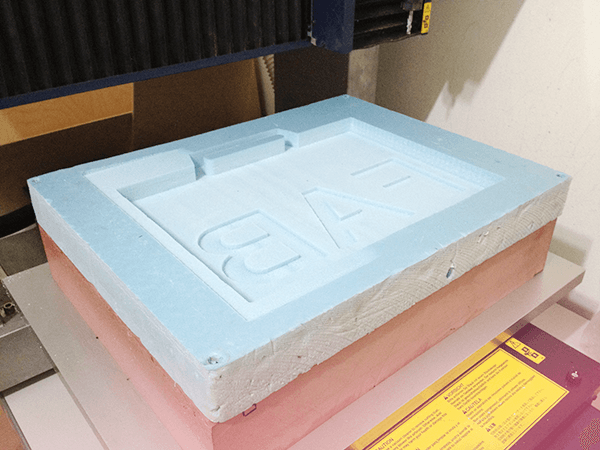

The goal of this week is designing and making a 3D mold (~ft2), and producing a fiber composite part in it. I wanted to make a hard cover bag this time. So I created a 3d model in Sketchup, and then milled out my mold by blue foam.

Blue foam's density is low, so I can mill very fast either in roughting and finishing.

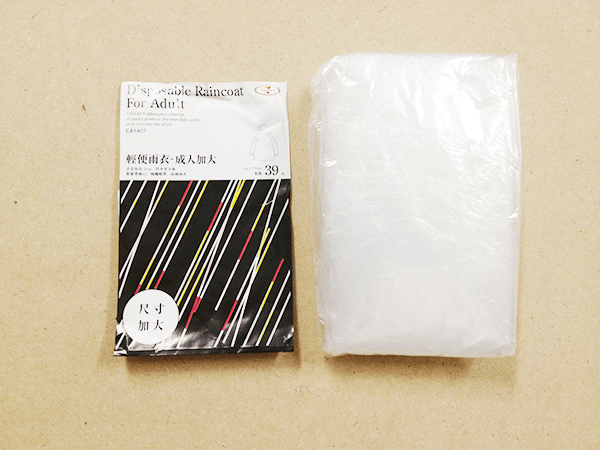

Here is the resin (exposy) I bought from chemical shop and I bought a disposable raincoat.

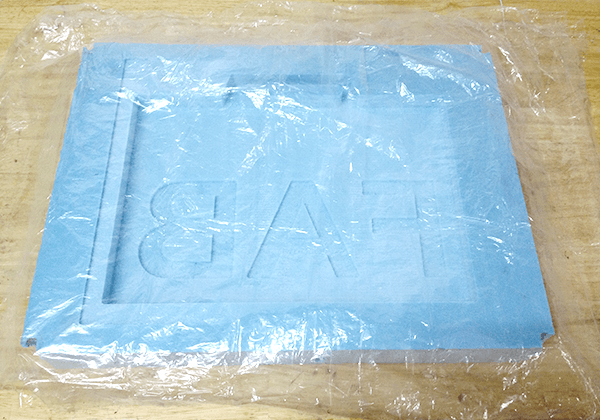

Disposable raincoat is thin plastic so that can be used to seperate the mold and my fabric. Also I bought some oil (SILCOTE) for releasing my fabric from disposable raincoat. For doing this, the mold can be reused.

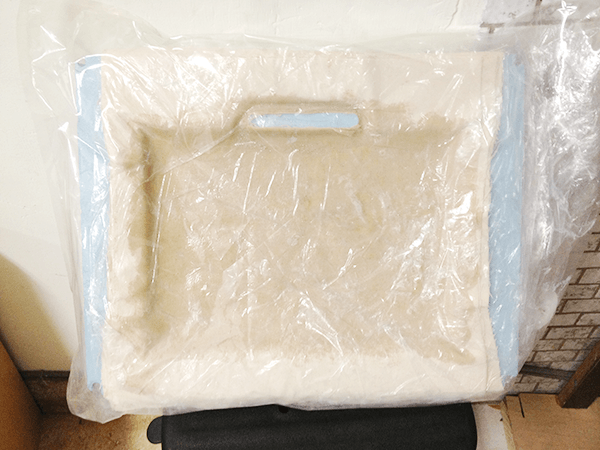

I mixed resin and soaked my fabric. In the first time, I tried 4 layers, and vacuumed.

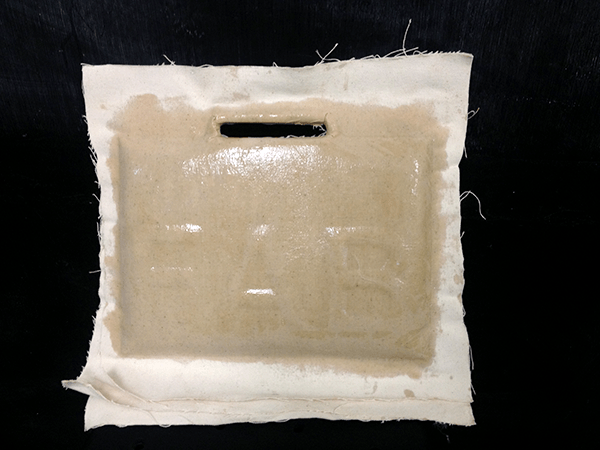

1 dsy later, The material became very strength, but words are no clear. I guess that is because:

- The vacuumed bag is to old, so the air goes in to the bag slowly.

- I put too many layers. Mayber 2 layers is enought.

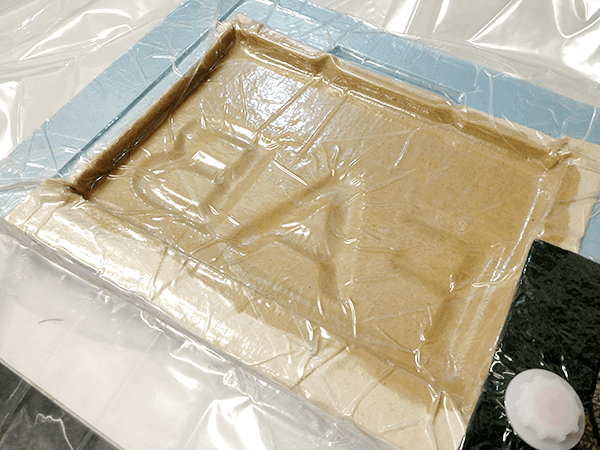

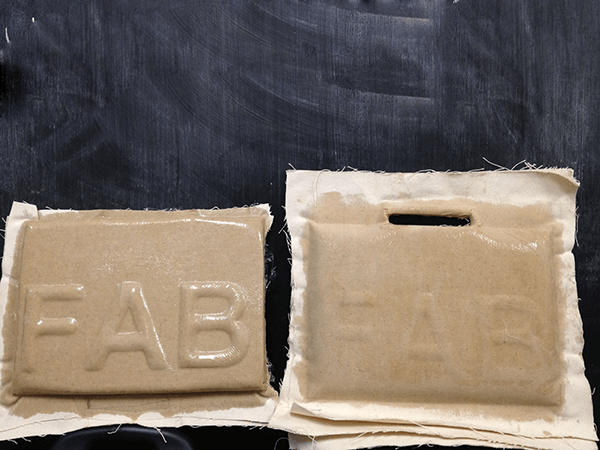

So I decided to make a 2nd one. The second run seems better. My instructor gave my a brand new vaccum bag, and put ad scrub sponge below the vaccum port. Please see the left bottom of my picture below.

The left hand side is the result. It is better than the first one.

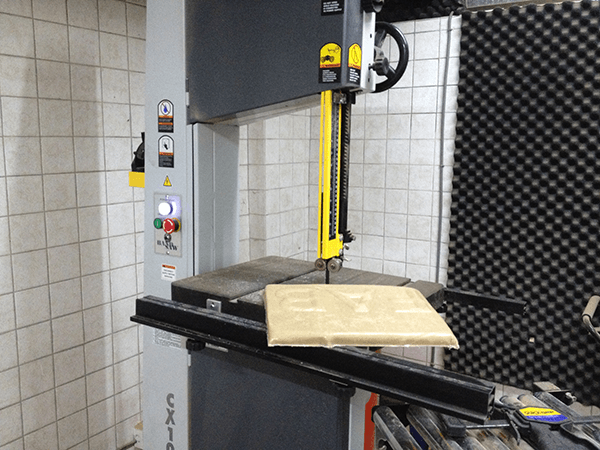

I used band saw to cut the shape I want. It made lound noise when I cut the cured resin. Please be careful and concentrate if you wnat to try this machine.

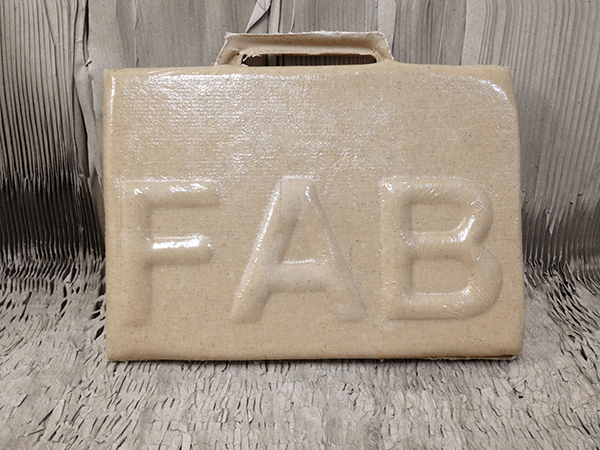

Here comes my hard cover bag.

source file: composite_02_02

:)