Birdview

Overview

The point of this is probably lost unless one understands the object itself and its goals. I've chosen to focus on the bullet vibrator at first and if time allows make a second iteration of a dildo with an inbuilt vibrator and a pressure sensor to regulate the strength instead of a button, such as the one the bullet vibrator has. I have applied the applications and implications process for both of these even though one of them is uncertain.

I would recommend checking out the Final Project page to get a deeper understanding of the project itself.

I said what what in the...

What What

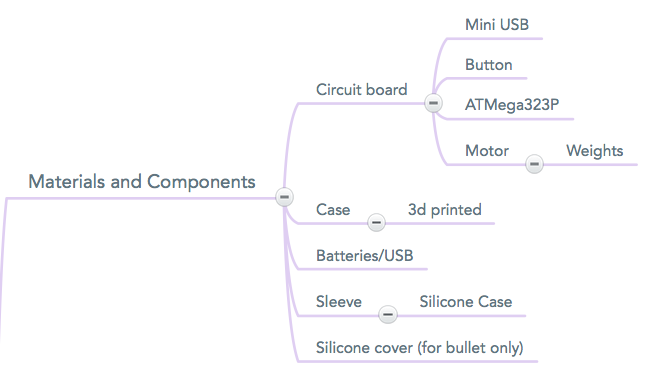

Below is a complete component listing for what my bullet vibrator will be made of. There's been a lot of back and forth for how this was to be made. In the end I came to the conclusion to have a Bullet vibrator which will fit inside a silicone shape, much like the  sharevibe dildo but with a multitude of different shapes.

sharevibe dildo but with a multitude of different shapes.

Circuit Board

The circuit board for the bullet vibrator required unexpected changes. What's new from the first iteration of the board I made in week 6 is that I wanted to allow for users to reprogram the vibration patterns post-production. As you can see it now says ATMega instead of an ATTiny. This is because the mini USB communicates in software serial which the ATTiny doesn't, to make this work I would also need an FTDI chip.

Casing and Usage

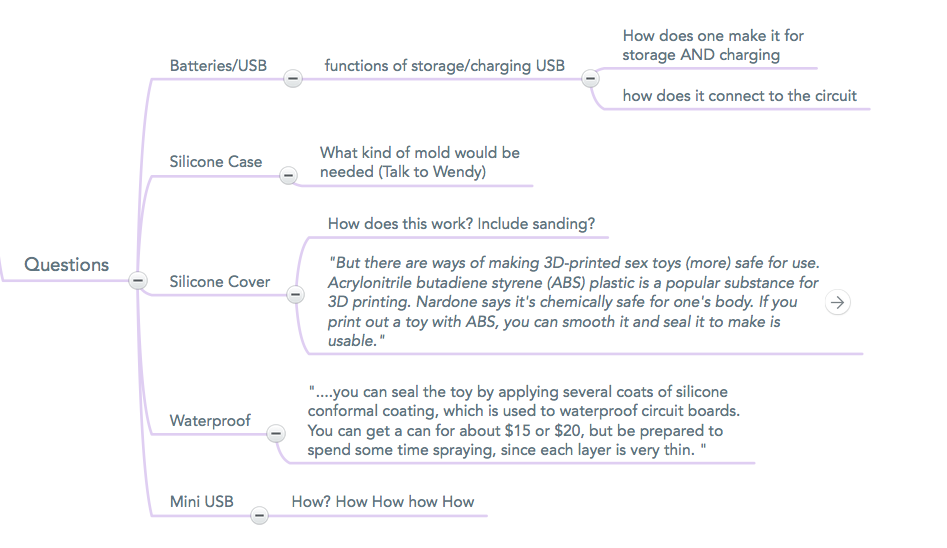

The case for the bullet would be a silicone mold. I tested the silicone combination in week 9 which gave good results although it was too sticky and should be made stretchier in order to make a good sleeve that would be easy to remove from and pull over the bullet.

While looking for other similar projects and objects I found an interesting article on the safety and potential health hazards of making a 3d printed sextoys. It highlights the importance of making a good surface for the toy and offers solutions:

The smoothing can be done with a sander or chemical bath, and Nardone says you can seal the toy by applying several coats of silicone conformal coating, which is used to waterproof circuit boards. You can get a can for about $15 or $20, but be prepared to spend some time spraying, since each layer is very thin.

Another great discovery I made through the article was finding that ABS (the plastic most use when 3d printing) is body safe so the bullet vibrator could be used without the silicon case as a non-penetrative clitorial stimuli.

I have yet to find out how body-safe the silicone conformal coating would be though; if the coating isn't bodysafe it wouldn't be a disaster since I'm not relying on it for the product.

Occupied Territory?

There are others who have visited the land of sextoys and open source as well as sextoys and local manufacturing. A territory which has yet to be explored is the land of sextoys where opensource and local manufacturing would merge.

This is where I aim to wander.

Comingle - The Mod

The main occupant of the land called Open Source Sextoys is Comingle who introduced  the Mod. Their product is open source and programmable for the user, how achaivable this is I have yet to understand and manufacturable on your own is close to impossible. Here's the link for their website.

the Mod. Their product is open source and programmable for the user, how achaivable this is I have yet to understand and manufacturable on your own is close to impossible. Here's the link for their website.

Dildo Generator

The dildo generator page is  creative commons licenced and allows the user to create their own dildo shape and share it with others (see below). There's one restriction which is that one can only make a dildo shape as long as the shape can be built by rotating a spline. Once this shape has been created it is quite possible to 3d print it, if the size of your printer allows for such. Here's the link for their website.

creative commons licenced and allows the user to create their own dildo shape and share it with others (see below). There's one restriction which is that one can only make a dildo shape as long as the shape can be built by rotating a spline. Once this shape has been created it is quite possible to 3d print it, if the size of your printer allows for such. Here's the link for their website.

MakerLove

MakerLove offers a wide variety of sex toy designs that are 3d printable and sparked the basis for the article I previously mentioned. They are limiting their offers to designs which fit with the bullet vibrator they sell so the users would have to buy these separately in order to have a complete toy. The picture below is an example of their design. Here's the link for their website.

Materials and Components

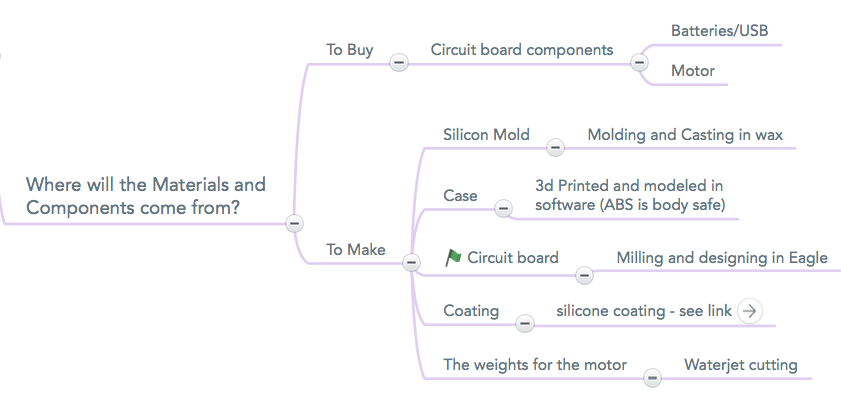

The goal is to have as much as possible makable from scratch so that users could build their own from scratch as well without buying anything unless they want to. Check  this image to see the section in my mind map on materials and components.

this image to see the section in my mind map on materials and components.

To Buy

The Hardware

The components for the circuit board, all aquired through the FabLab NZD

- 3*10k Resistors ~$0.2

- 49.9 Resistor ~$0.2

- 2 * P Mosfet ~$1.01

- 3 times 2 Pinheader ~$

- ATTiny 45 ~$3.69

- Resonator ~$

- 2*Capacitors ~$

- Regulator ~$5.09

If I was to make the dildo I would also need to buy

To Make

The most interesting part about this section is that I can buy the Motor but I can't buy a weighted motor which means that I'd have to make the weights myself. Fortunately FabLab WGTN has access to a waterjet so for me this isn't an issue but for the consumer they would need to order one seperately which is difficult. Luckily this is where the kits of my project fits in.

- Silicon Mold ~$???

- Wax ~$???

- Silicone ~$???

- 3D Printed Case ~$???

- Circuit Board ~$???

- The wights for the motor ~$???

- Coating ??? ~$???

Full Cost

The full cost is yet to be estimated.

To Do

Everything. Basically. Most pressing is the new circuit board which would enable programming through the mini usb connection. Beyond that I need to make the 3D case and the silicon cover for the 3D case.

Questions

I have tons of questions.  Here are some.

Here are some.

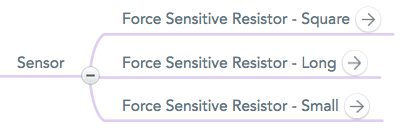

Force Sensitive Resistor

Force Sensitive Resistor