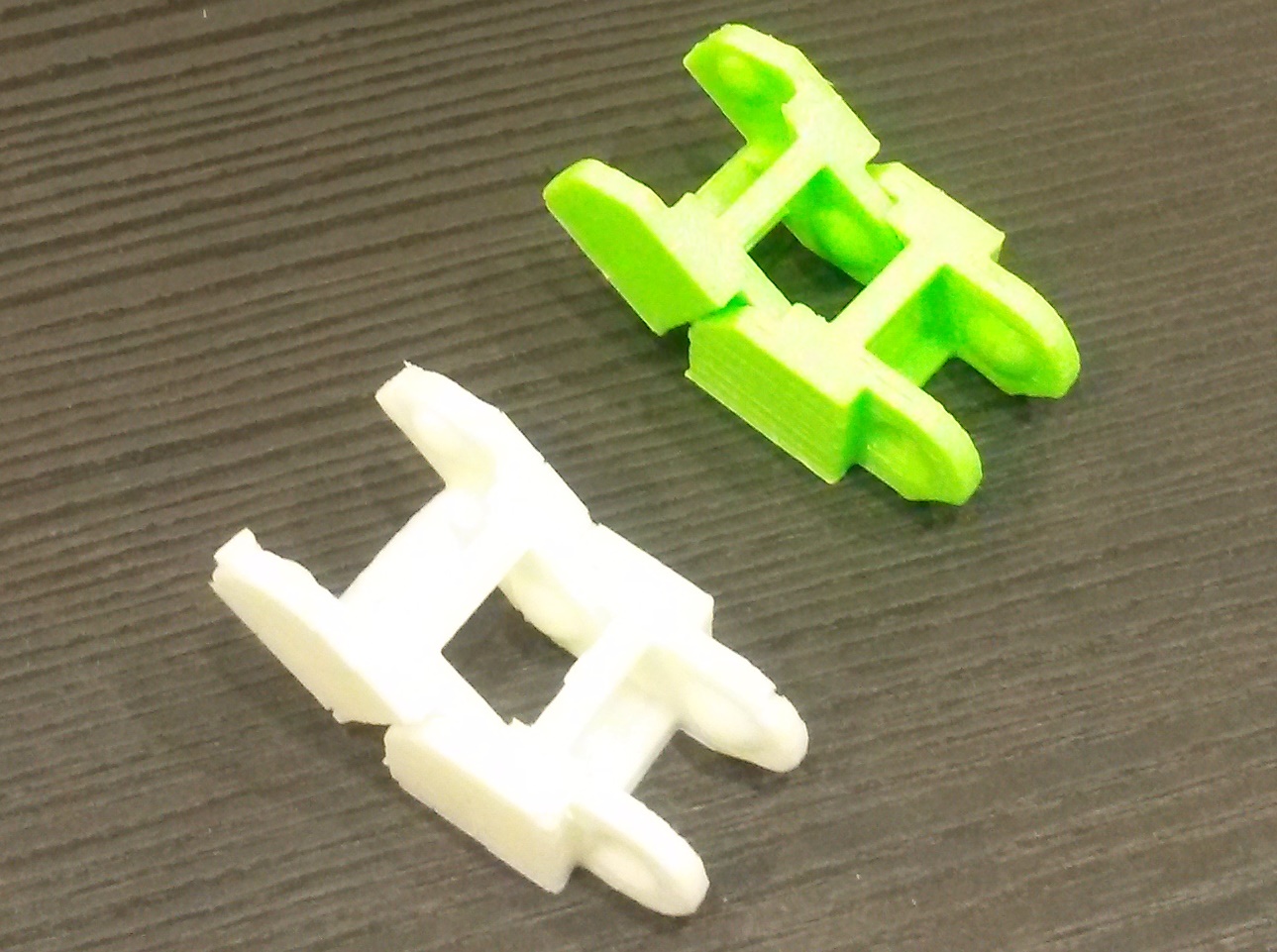

This week I decided to do something useful and I chose cable channel, witch looks like a chain.

First I took single chain links of the cable channel to prepare a silicone form for molding.

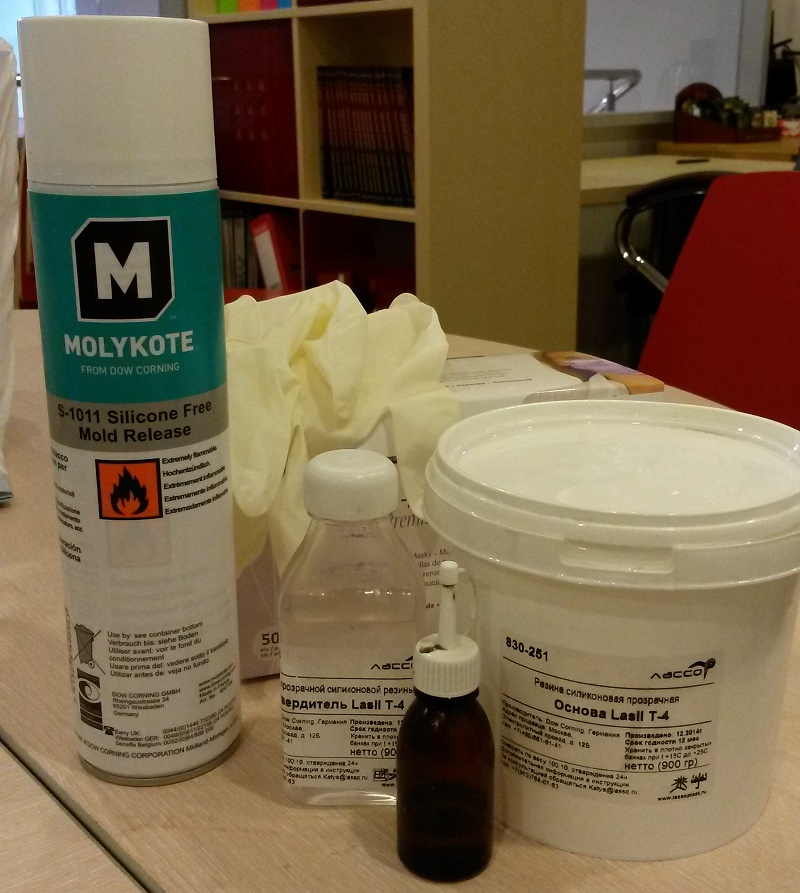

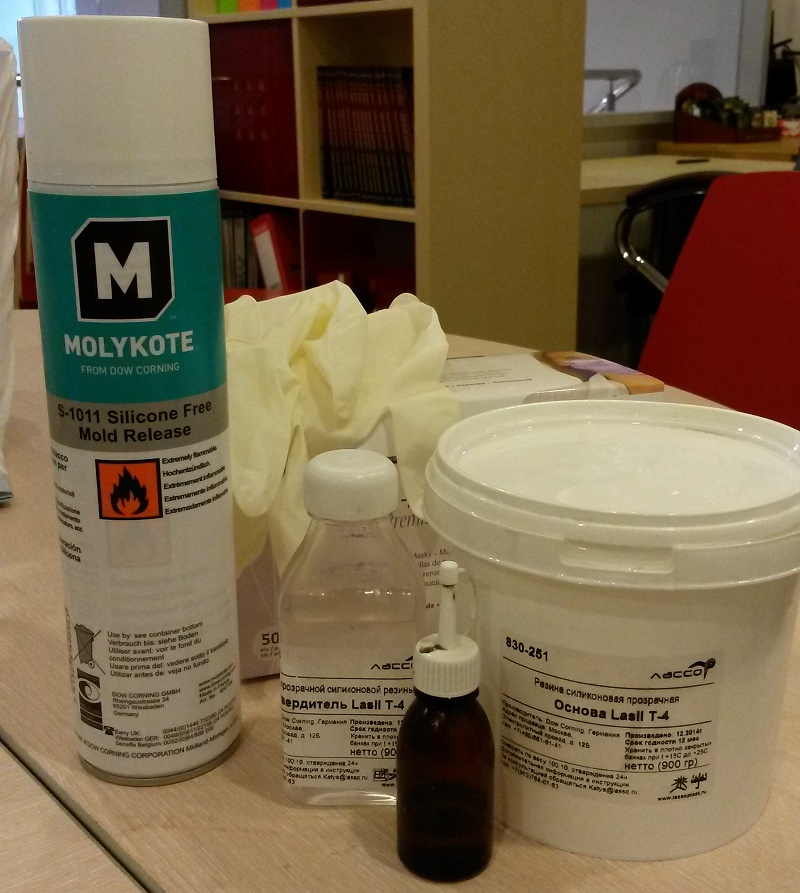

We use glassy silicone rubber Lasil T-4 to make the form. You have to be very careful making the solute and put all ingredients in in precise proportions.

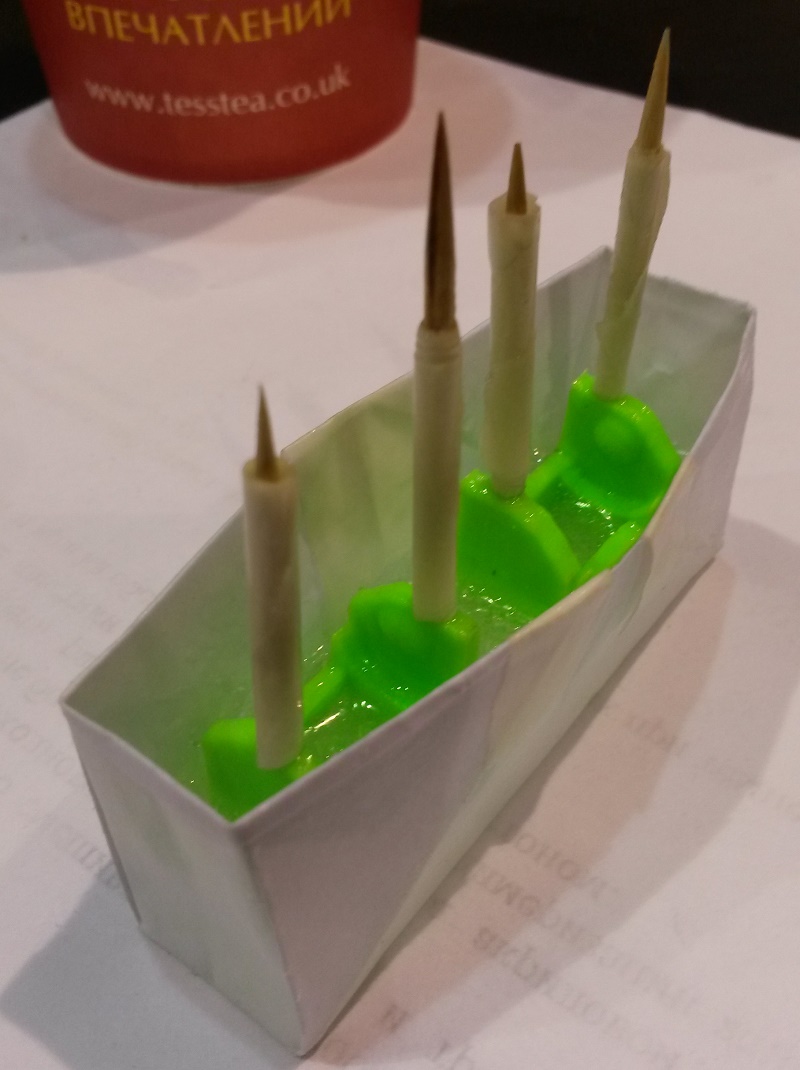

I made a little paper box and put there two parts of the chain. After that I poured silicone mass and filled a part of the box. The chain links have complex shape that is why it should consists of two parts.

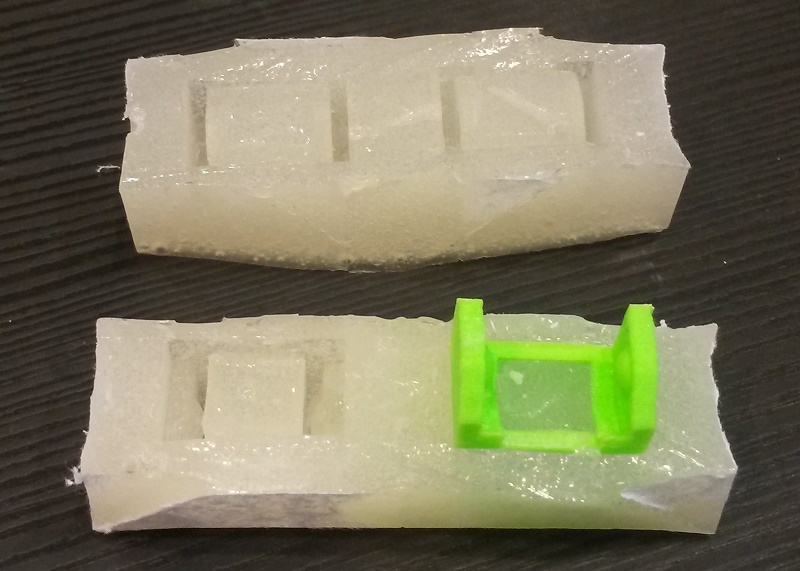

It took about 4 hours to solidification the rubber mass. Before making second part of the form I treated the form and first part with S-1011 Silicone Free mold realease and made canals for plastic.

After that I took away the paper box and separated the silicone form in two parts to took off the parts of the chain.

For casting we use LasilCast 2. It should be accurate mixed in the ratio 1:1. The main task - not to do the bubbles. Plastic mass hardens very quickly and you have about 2-3 minutes to fulfil the form.

As a result we have:

To finish this task - I have done the medal of FabLab. Here is the file.sldrt

The workpiece part was made on MCV-300.