I've never really worked with electronics before, so I was a bit nervous.

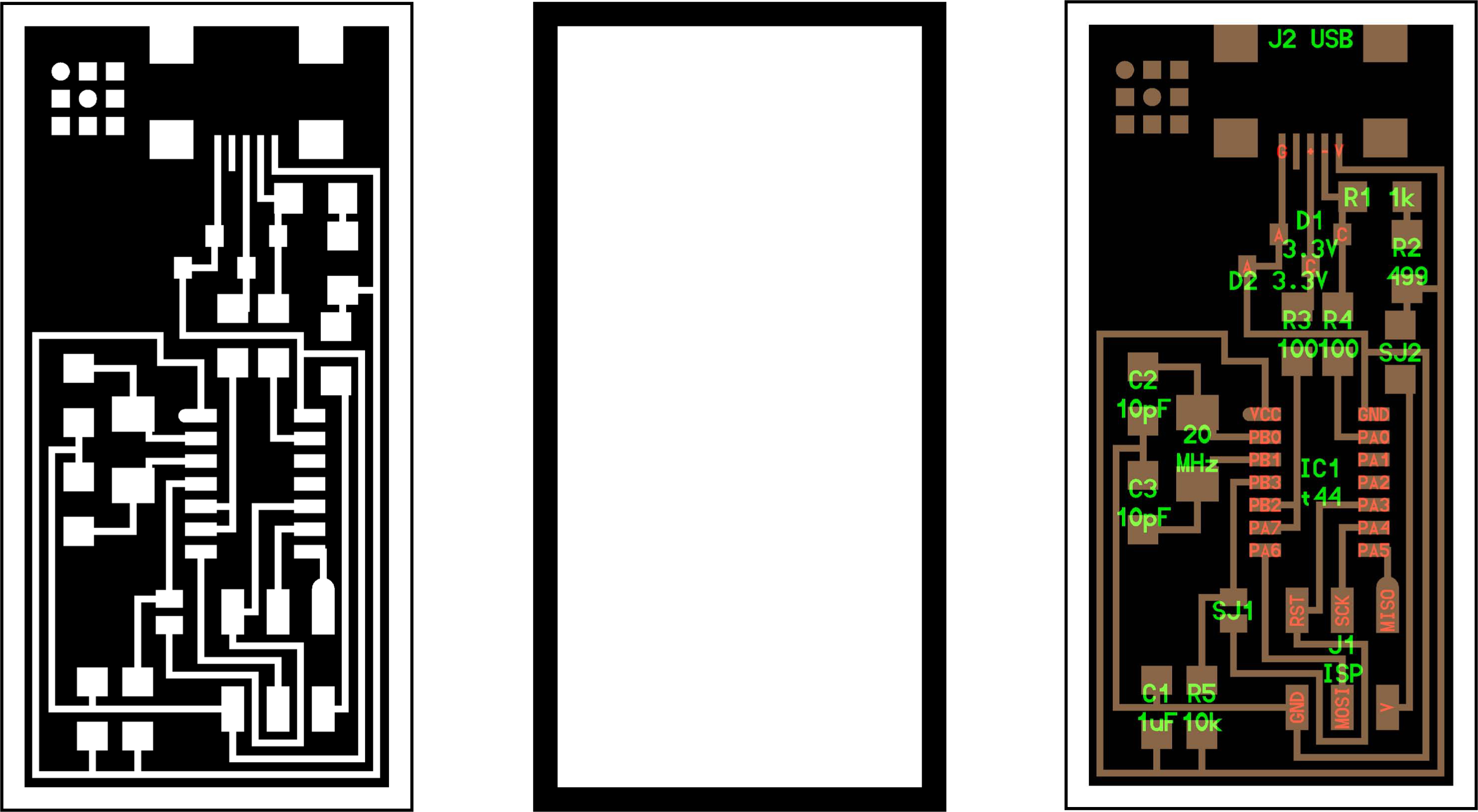

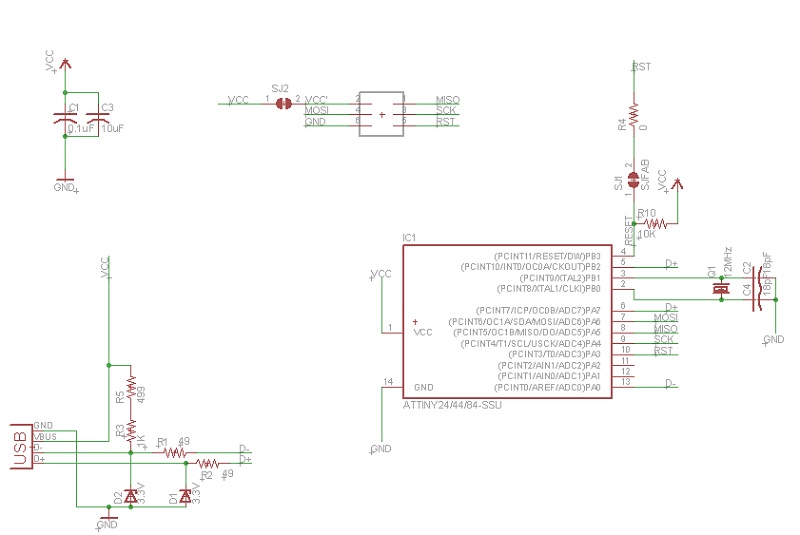

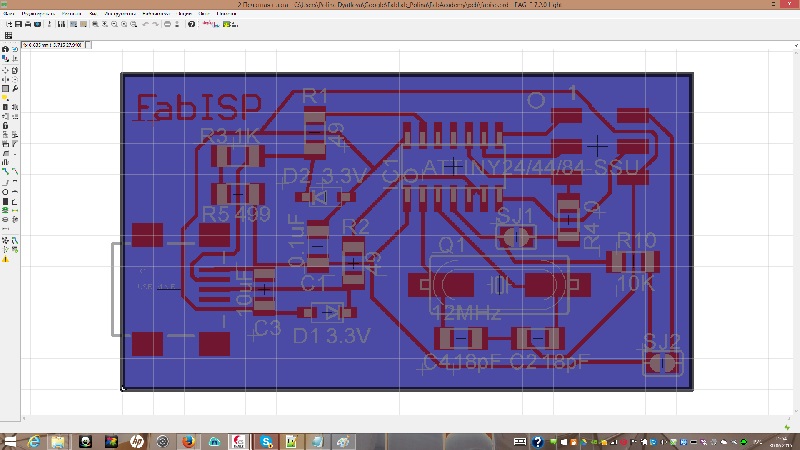

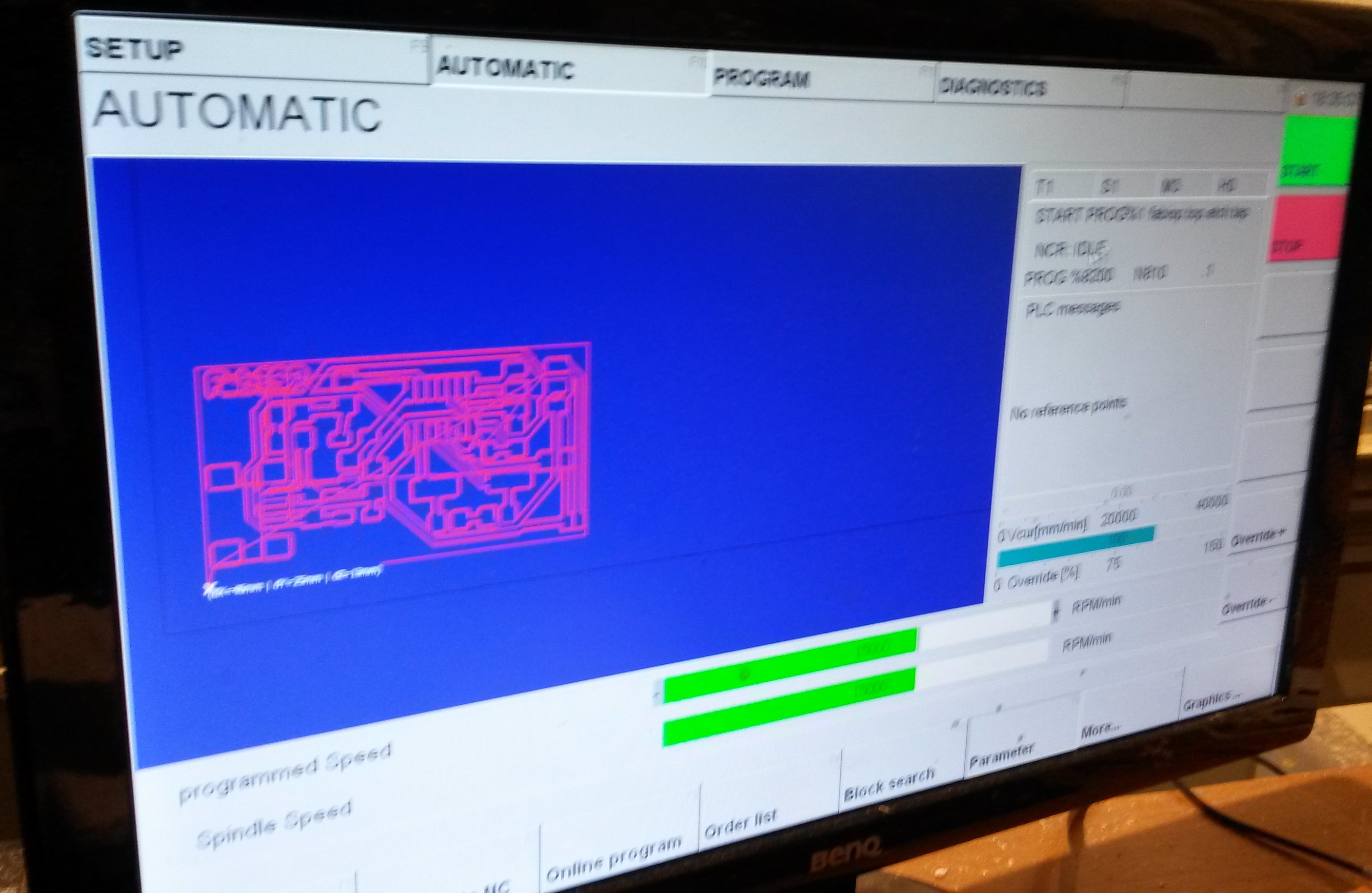

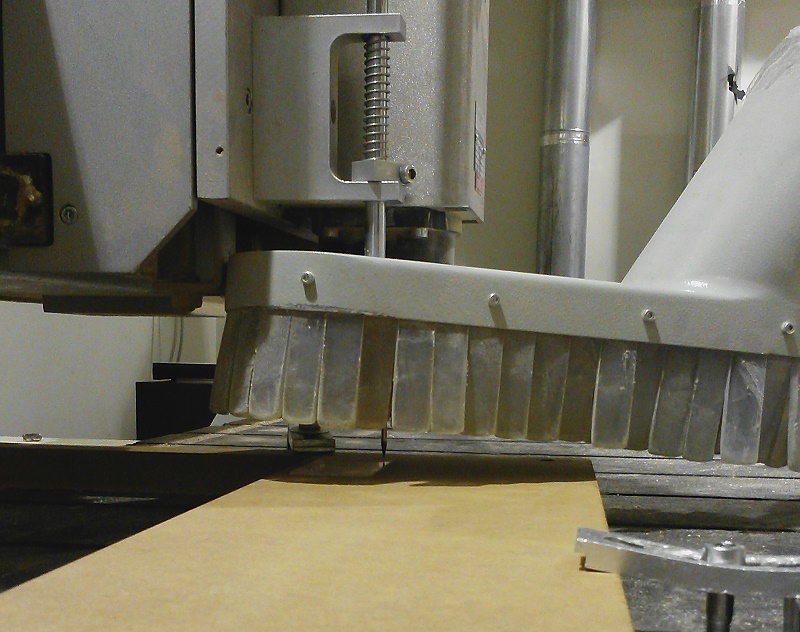

The assignment was to make an electronic circuit out of a copper board and small component such as resistors, capacitors ... The board i've done was a "FabISP" one, wich is well documented. First things to do was to get the png file and send it (via the fabmodules) to a milling machine to draw the electronics circuits by removing the material where it shouldn't have conductivity

I use Eagle 7.2.0 to program the board

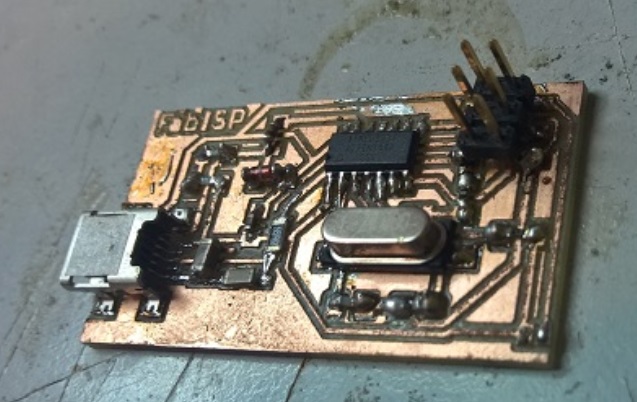

Though I get my board ready to be weld. The copper is like small electric wire and the components will be like bridge between them.

The welding requires much patience because the parts to be weld was smaller than a millimeter, but with a lens it was fine

This board will be used to put the boot code (a basic operating system) on a micro-controller so I could start using it.