Our assignment for this week was " design and make a 3D mold (~ft square), and produce a fiber composite part in it"

For the beginning I decided to make a cap for mannequin we coincidentally had in our lab. I understand that basically we had to make our own mold, but we had really big problems with our shopbot machine for really long time! There was some problems in g-code tranclstion to CNC itself and by the moment I made this experimens the machine wasn't working well yet.

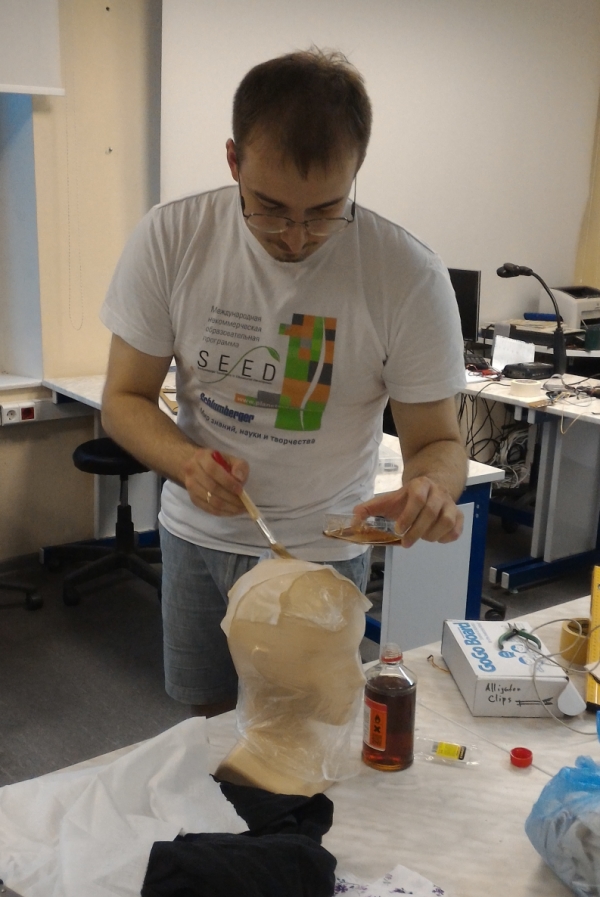

I used butyral phenolic clue (It seems to be more safe than epoxy and what's even more interesting - it can be a little elastic - that opens a lot of space for designing different costume details or many other things. And also result was really lightweight) and cotton fiber (which is plant fiber and is much more safe than the glass fiber), i.e. to use the mannequine as the mold, because we were having some problems with shopbot-machine at that time

|

|

I used plastic bag to save the mannequin from being clued to it's cap and started making composite layer by layer:

|

|

That's what I've got as the result:

|

The cap on the mannequin |

Cutted the excess fiber |

The cap itself |

That was really interesting experience and It made me understand the making of composite materials in a better way. I would like to make some researches later about the result parameters (strength, flexibility, elasticity) and later I would definitely like to try some other ways to make the composite and to implement some ideas on robotics with this (For that I will try making mold on shopbot machine for sure!)

Back to my main page