Homework assignment

Make something big.

Design

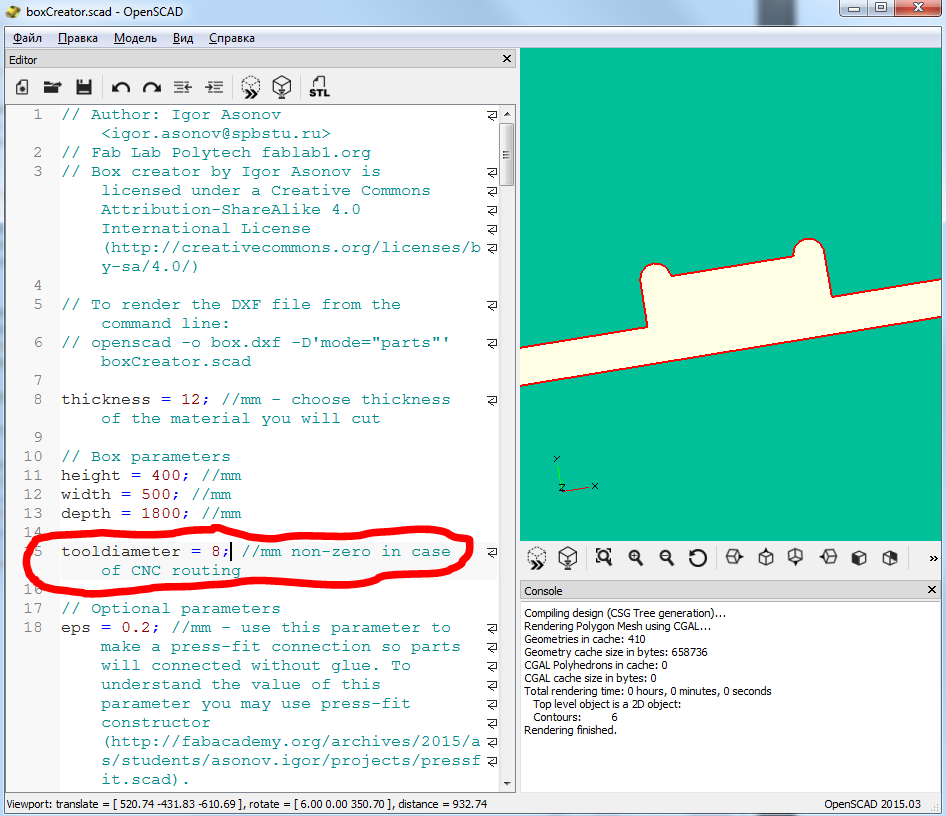

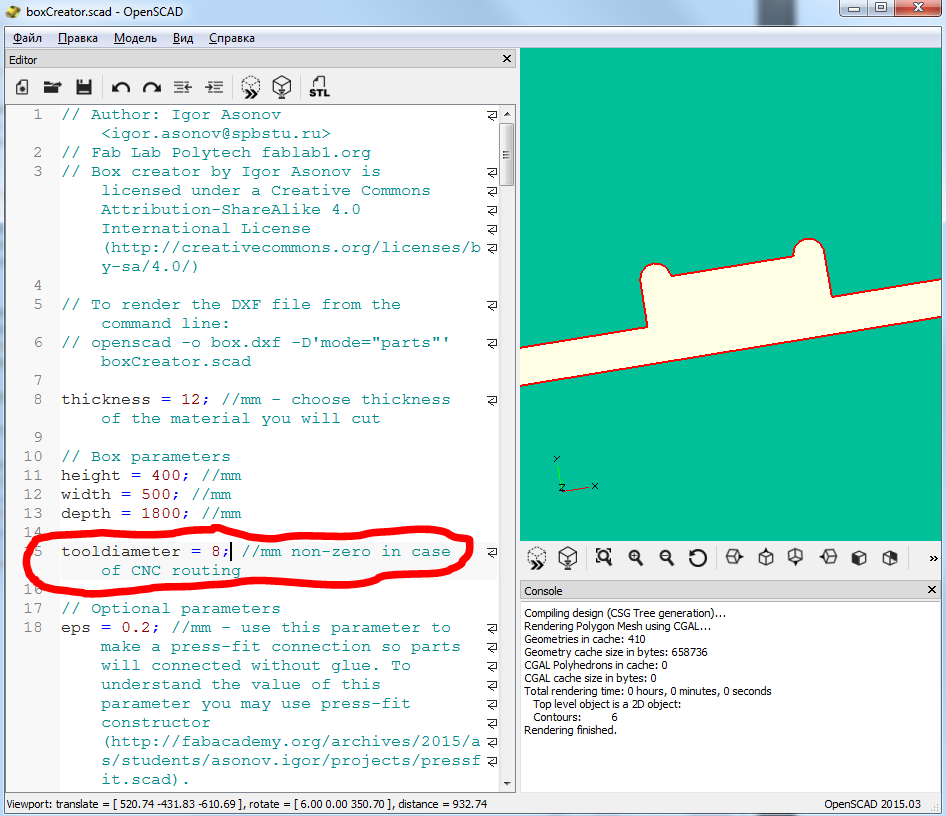

I decided to devide designing process into two parts: basic in OpenSCAD and final in SolidWorks, because it's easier to check the design by making an assembly. So I used OpenSCAD and changed my box creator to be used not only with laser cutters but with CNC router also. New parameter is "tooldiameter" - if it's non-zero there will be special openings for CNC router manufacturing:

There are several modes inside the program:

- "full" - drawing of the whole box with 6 sides;

- "full-1" - drawing of the box with 5 sides - you can put anything inside the box;

- "half" - export only half of the box;

- "door" - drawing of the box with door;

- "3dview" - preview of half of the assembly.

I created design using "door" mode and export it to dxf-files. These files were imported in SolidWorks 2013 where I made parts using imported sketches, designed two new parts (partitions and corners) and added cuts for them, then made an assemly:

Make

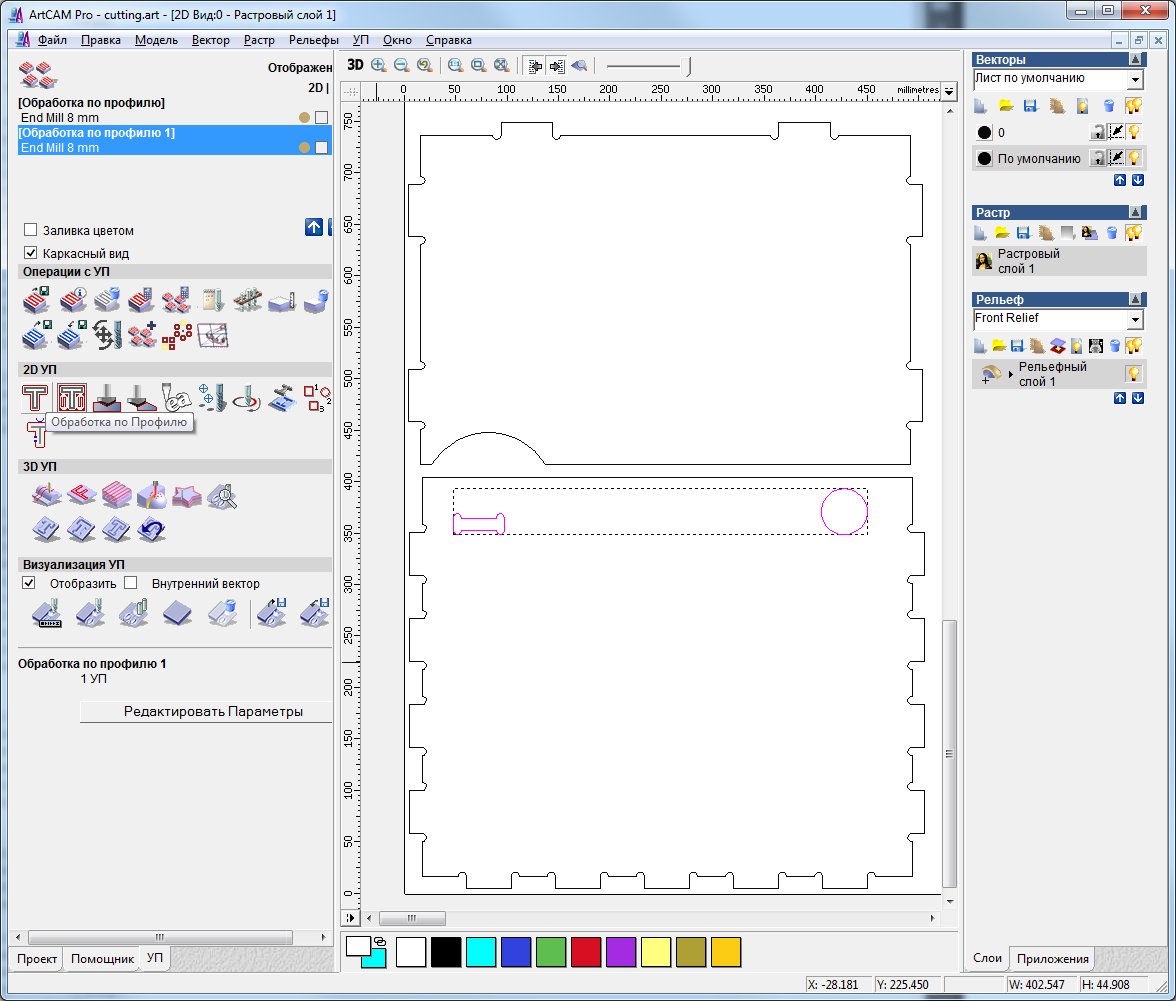

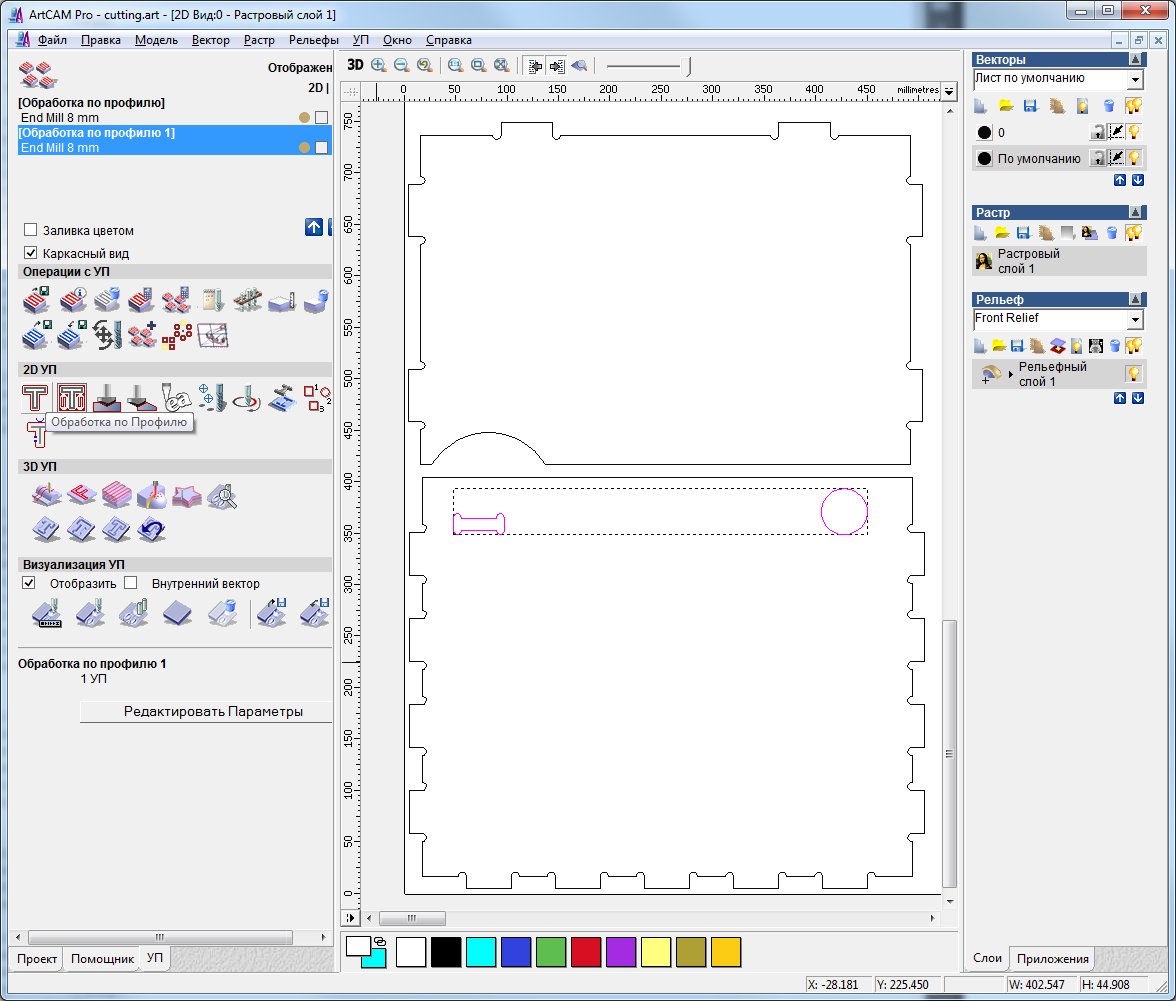

I used ArtCAM to generate g-codes from dxf-file (exported drawing from SolidWorks). If there are holes and cuts inside your parts - they should be processed first. Choose them in ArtCAM, go to Processing tab (at the left bottom corner) and press "Profiling" (looks like "T"):

Choose "Inside" and go trought wizard (it will ask you the depth of cutting, tool parameters) and press "Calculate now". After the g-code generation you can save it using menu "G-code->Save g-code..". After you cut internal things on you part - made the same with outside profile of your part.

Choose "Inside" and go trought wizard (it will ask you the depth of cutting, tool parameters) and press "Calculate now". After the g-code generation you can save it using menu "G-code->Save g-code..". After you cut internal things on you part - made the same with outside profile of your part.

Parts of the system connected with each other using friction.

Parts of the system connected with each other using friction.

I used 8 mm tool, 1500 mm/min working feedrate and 15000 rpm for spindle. Material was 1.2*2.4 m OSB wood.

Source files (dxf, SolidWorks 2013): zip-archive.

Choose "Inside" and go trought wizard (it will ask you the depth of cutting, tool parameters) and press "Calculate now". After the g-code generation you can save it using menu "G-code->Save g-code..". After you cut internal things on you part - made the same with outside profile of your part.

Choose "Inside" and go trought wizard (it will ask you the depth of cutting, tool parameters) and press "Calculate now". After the g-code generation you can save it using menu "G-code->Save g-code..". After you cut internal things on you part - made the same with outside profile of your part.

Parts of the system connected with each other using friction.

Parts of the system connected with each other using friction.