make something big

A joint.

SMAW welding

I have done some CNC milling in the past, both as a group and individually. So for this week, I wanted to learn how to weld. I have been wanting to know how to weld for several years now -- my mind is bursting with ideas for furniture and other things to make with steel and other metals.

The workshop at CEPT has an old(ish) stick welding machine (Shielded Metal Arc Welding or SMAW), and we need a more heavy-duty table to support the laser cutter. Right now, the Epilog is on an old drafting table which shakes quite a bit -- thus the cuts can be shaky sometimes.

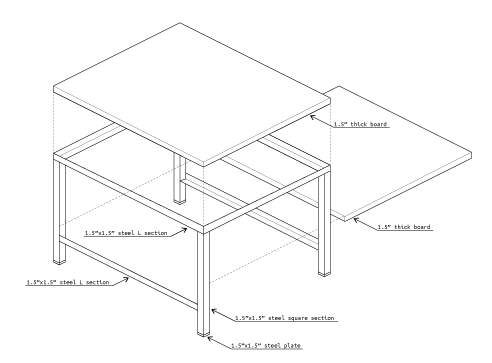

My friend Nitin and I came up with a design for a table that would use standard steel sections and would not only be nice and sturdy, but would be very attractive as well.

The table design.

Over-all the welding went fine. Though the machine was a little... hmmm jugaad-y, it did work and no one was electrocuted. In the future, I will get some acid to clean the to-be-welded areas so that the joint will me stronger and to compensate for any imperfections in the cheap welding sticks.

Inside of joint.

Up until now, we were able to make the frame for the table top and cut the other parts to length. We need to decide what the top and shelf will be made out of. I'm thinking either plywood or Corian.

Table-top frame.