3d scanning & printing

3d scanning

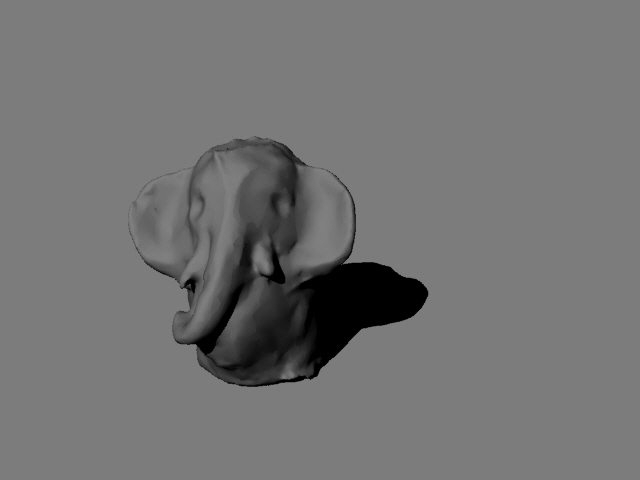

In India, everyone has a Ganesh. Ganesh is the elephant-formed god that offers people good luck and adorns every nook and cranny here; in fact, while each temple is devoted to one of the over 1000 gods in Hinduism, the entrance to every temple is protected by Ganesh.

"Ganesh" | artist unkown

The space that FabLab CEPT is in is adjacent to the pottery studio, thus there are many left-overs around. While the space was being prepared, I found a small Ganesh; I decided that it would be perfect to protect the FabLab.

a render of the .stl file in Rhino5 (Rhino Renderer)

3d printing

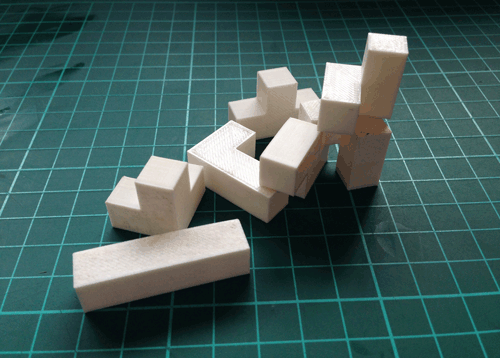

quadominoes

Useing a MakerBot 2, I made a set of "quadominoes." Quadominoes are the set of continuous solids formed when cubes are connected at endge and vertex. They are a 3d and simplified version of pentominoes, a common 2d puzzle. There are a total of 8 different configurations makeing all sorts of interesting (and some not-so-interesting) shapes. Both the .3dm file and the .stl file can be found below.

quadominoes

quadominoes

3d printing "impossible" object

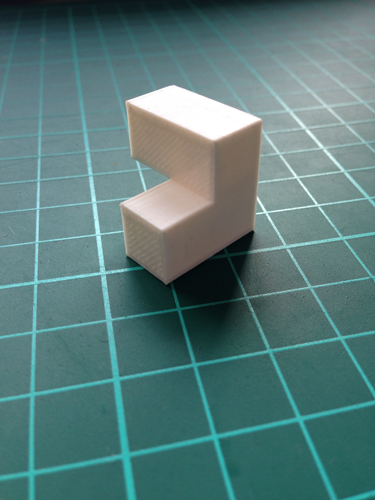

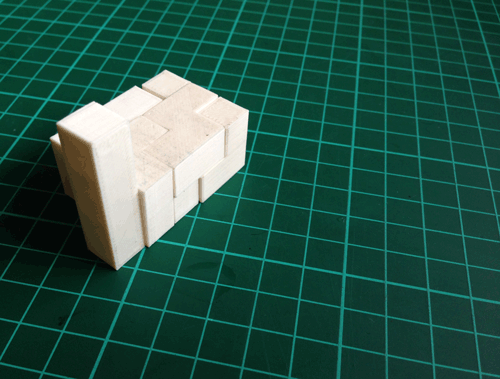

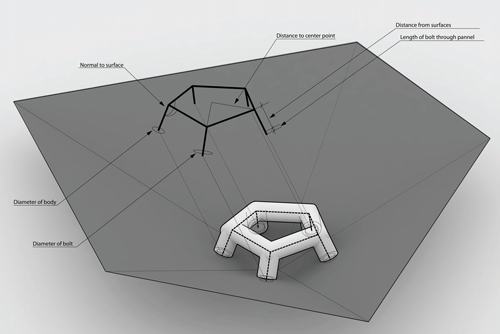

generative joints

FDM printing

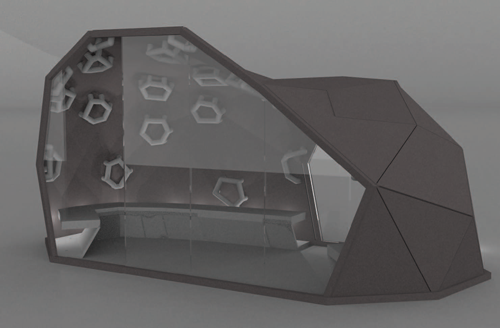

Several frinds and I had a design for a bus stop that encorperated several dozen custom panels that whould be connected together with joints like those made by TriPyramid -- a company that makes stainless-steel connections between glass panels (most noteably for the NYC Apple flagship store). Ours where more chunky, and the final material was yet-to-be-decided, but the 3d models for them were automatically generated based on the mesh that defined the geometry of the panels. This was done in Grasshopper wtih a script that iterated through mesh nodes and implimented logic, as represented by the image below.

algorithmic schema

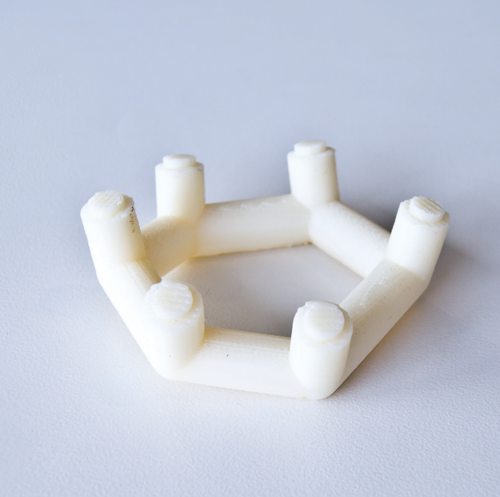

These were printed in ABS on a Stratasys Dimention Series 3D printer. no support material was nedded (if I remember correctly...).

one joint

another joint

a final rendering of the project

3d printing with a laser cutter

squishy prints

I also want to share some research that I did while a UROP with the Mediated Matter Lab at the MIT Media Lab. Based on an idea by Yoav Sterman, I was able to use a standard Universal laser cutter (at CBA) and sinter together ubiquitous plastic pellets into a 3d object. This was all done by hand, more-or-less, a jig was made to allow for manual control for the z-axis, and each layer was sintered via a seperate print file sent to the laser cutter. This heped produce quickly-printed, large scale prints that were also strong and cheap. While they lacked high percision, they were made of standard materials that are sold in bulk (usually for injection molding) they could be semi (if not fully) functional.

top (kind of)

bottom :: note burning and the fully melted sections