Schnyder - 3D Printing and 3D Scanning: A Small Pump and a Mess

of Mesh

For the 3D Printing project, the task was to design an object

that couldn't be made with a milling machine, laser cutter, or

vinyl cutter. I interpreted this as a single object that couldn't

be made from one piece on the machines. An easy object for this

task would have been an egg or some shape that had an undercut.

Instead I tried to create a small pump from a single 3D print.

The inspiration for this single print design was an elephant that I

printed from Thingiverse. The elephant was a single print and was

designed so that pairs of its legs would swivel around an axle and

that its head would move around a socket. I got it in my head that

designing an object with moving parts would be the ideal first

experience with a 3D printer.

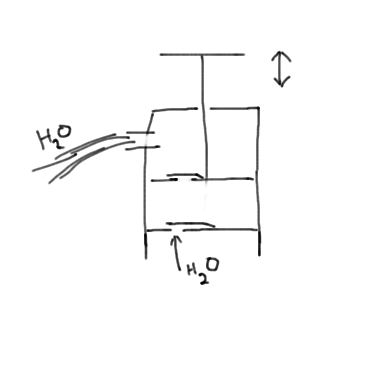

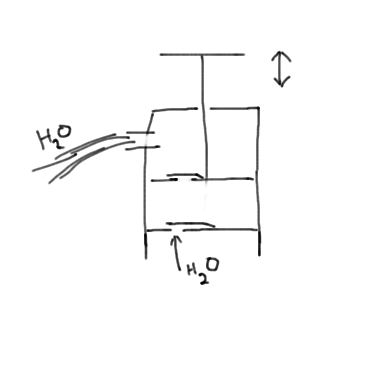

I created the pump using SketchUp. I made a space of 0.005" between

the cylinder walls and the piston and the opening at the top of the

pump and the shaft attached to the cylinder. I figured that there

would be some filaments leftover from the print that I would have to

break (as was the case with the elephant), but I wasn't too

concerned about those affecting the pump's performance.

For the valves, I tried to imitate the hinge that I've seen on small

plastic cases--a half loop of material. Since I wasn't using a very

flexible material for the valves, I added a little nub of plastic

that would partially fit into the holes the valves were controlling.

I assumed that if there were some filaments that I could break them

free after printing with some careful work with a nail or some other

probe.

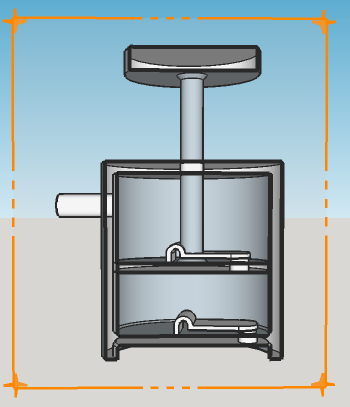

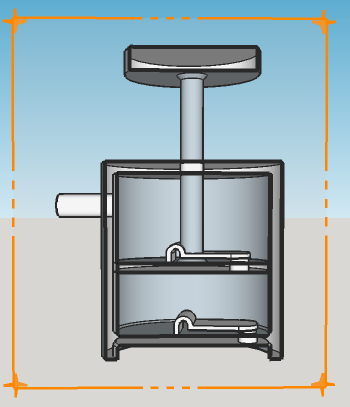

I printed the design using MakerWare on a Replicator 2 with ABS. For

the print settings, I created a raft but did not create supporting

structures. I also changed the scale of the object because I was

nervous that the print would take too long. In hindsight, not having

the supporting structures and changing the scale were not wise

things to do.

I did not watch the whole print but I did see both valves, the spout

and the finger grip at the end of the pump's shaft. When I saw the

valves I knew that I had made a mistake in sizing gaps in my design.

In hindsight, the gaps should be greater than the filament width

from the printer. In the case of the Replicator 2, the width should

have been greater than 0.020". In my design, I used gaps of 0.005".

Everything was fused. The next problem was caused by the absence of

the supporting structures. There was a slight problem with the

underside of the spout, but I canceled the print when the printer

started on the finger grip. This part of the piece had no form.

Ideally I should now know that I shouldn't undertake complex

projects without doing some tests on key components. When I try this

project again, I will test a couple of components of the design such

as creating a moving piston or testing valves without encasing them

in plastic so I can evaluate them. Based on what I saw during the

print, I should start my valve evaluation with a new design.

3D Scanning

For the 3D scanning project, I used 123D Catch in different

environments to capture a 3D images. The first object I tried to

scan was a wooden biplane toy. I put it on the floor of my kitchen

and tried a couple of scans.

Neither scan was satisfactory. At first I thought that it was

because the color of the plane was too close to the color of the

floor. So for the next capture I used a contrasting surface. In both

cases I used about 25 pictures to load into 123D Catch. The second

capture was even worse than the first. The background was stitched

into the top wing of the biplane. In the next class there was a

discussion about the captures and that a single light source can

actually confuse things and that it is much better to capture images

in diffuse light.

For my next attempt, I used the photography table at AS220 and

captured close to 60 images to convert into the final 3D image. The

photography table has four lights surrounding the platform so

there were no cast shadows. The 3D image was much better, with only

a little webbing between the box and the bottle.

I went back to the biplane for the latest capture. It was a cloudy

day and I didn't use any indoor lighting. I also had the biplane

sitting on a lazy susan, so I moved the camera between 3 different

vertical positions and then would rotate the lazy susan to rotate

the plane. This results from this capture were better.