COMPOSITES

Goals:

Design and make a 3D mold (~ft2), and produce a fiber composite part in it.

Designing:

For this assignment I was thinking to design something related to the beach, some toy that people could play there. It will be only a prototype.

After seeing many toys in the beach, I just go for the beach racquets. I also want to protect people from the sun while playing and I design a sun visor.

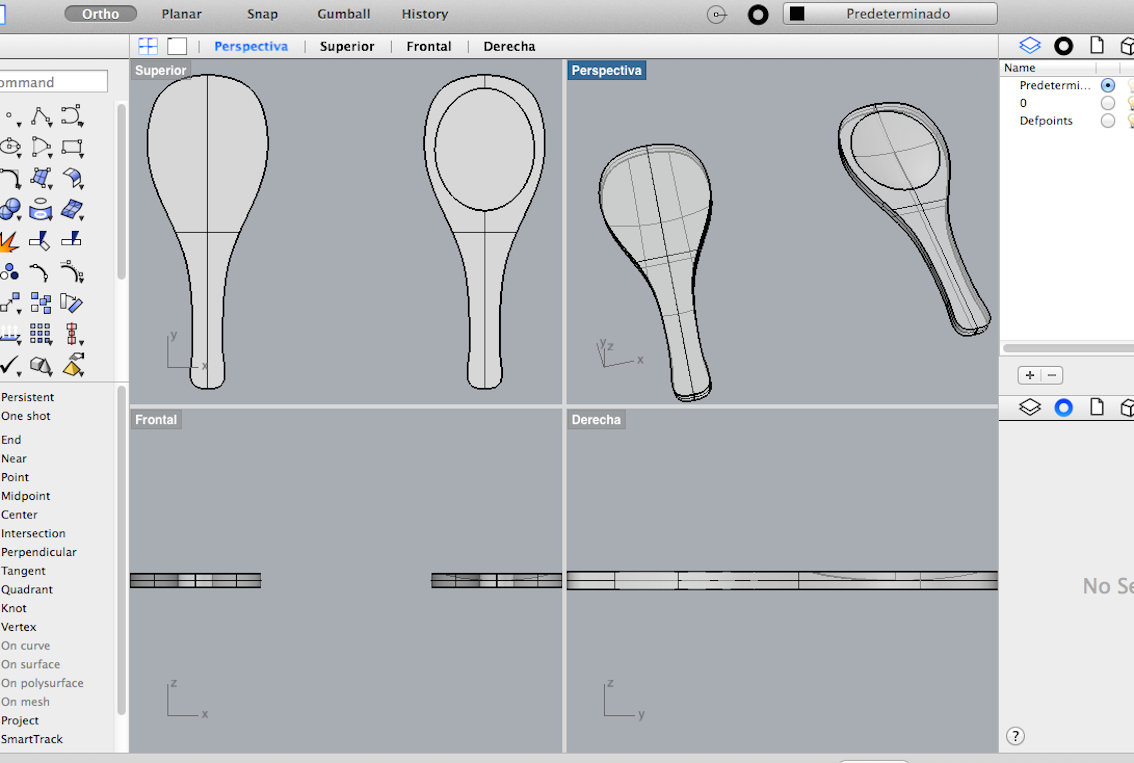

This is the result in Rhino of one of the bjects:

Milling:

To mill the foam I am using a Shopbot CNC machine from the Fab Lab Barcelona. It has a bit ball of 12mm, in the settings the machine is going to give three passes: the first pass is for cutting the shapes, the second pass is for making details and third pass is for giving more resolution.

Resin:

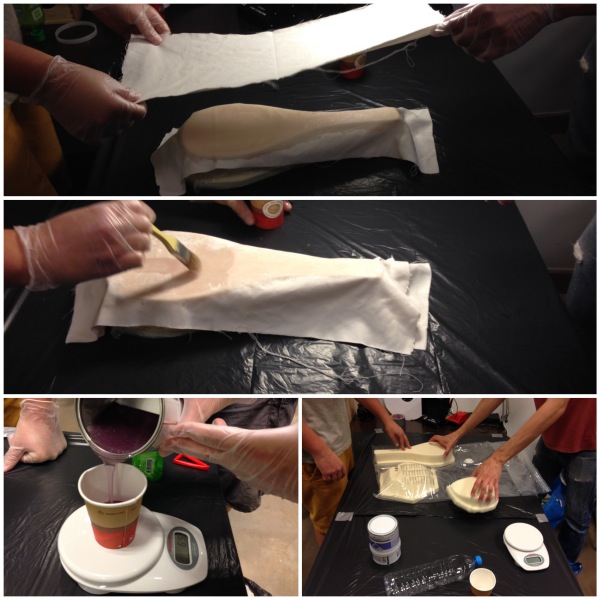

- You have to protect well before starting the process with the resin. First of all you have to cut a piece of fabric with the same shape as your object.

- When you have this done is vey important to follow some basic instructions:

- Put some films or plastic to the objects to give them a smooth surface.

- Mix the resin as the instructions says. In my case is 100gr of A and 50gr of B, two by one.

- Now give a hand of resin to the surfaces and place the fabric.

- Spread the the resin from the center to the perimeter.

- Repeat the process for with two layers at least.

After doing that you should put the objects in a plastic vacuum bag to absorb the air completely. And wait for it at least 24 hours.

These are some pics of the process and the final result:

What I learned:

The resin worked very well, even better as expected but the result it's not a very hard material. As I used fabrics, the material is not as resistent as others could have been. Anways, It was fun to see how easy is making objects out code, foams, and some little material. This is the begining for making other beach toys in the future.

You can download all the files related to this week here.