MOLDING AND CASTING

Goals:

The Goal of this week is to design a 3D mold, machine it and cast parts from it.

Designing the mold

I don't have so much time for this assignment so I try to get the fastest way and I try to make a chocolate out of a simple design. It will be the simplest and fastest way to do the assignment. The word “fast” and “assignment” shouldn't be written in the same sentence, I know very well I will regret in the near future.

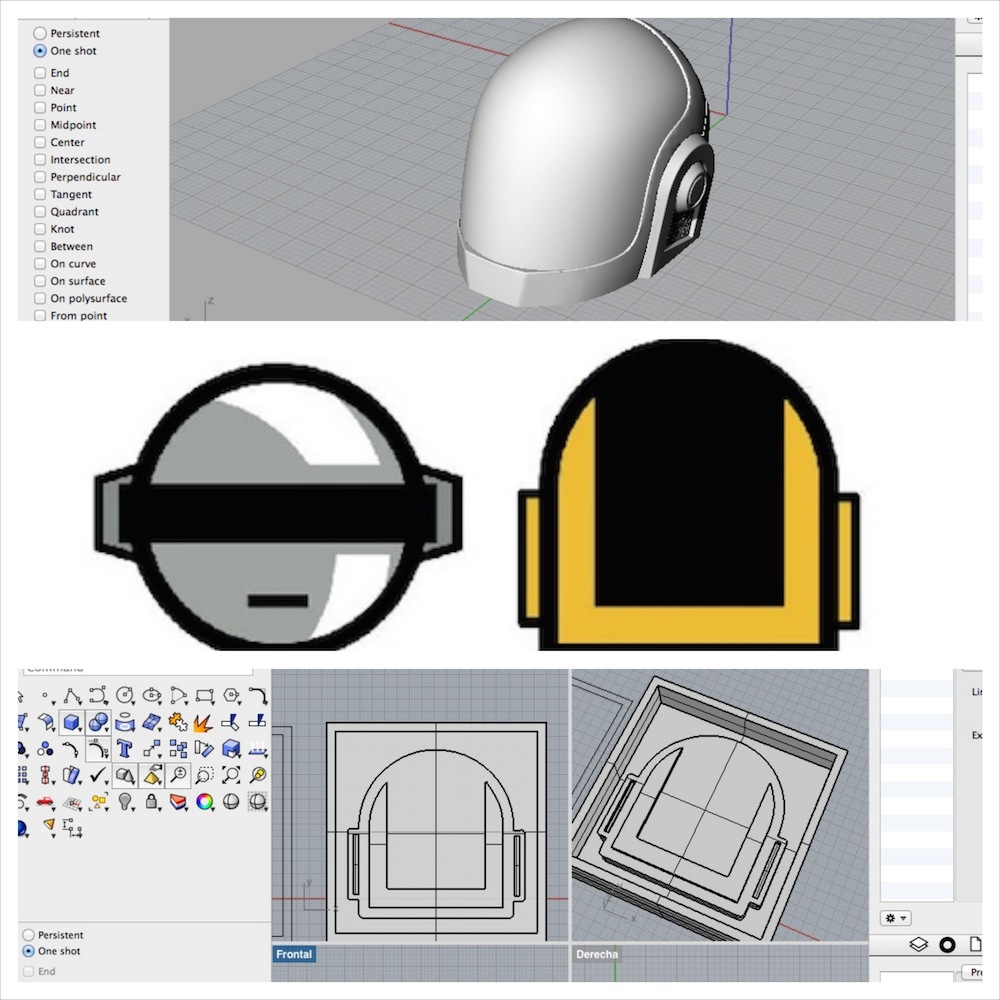

My first design is about making chocolates out of the helmets of Daft Punk band members. I think making chocolates of their helmets will be fun and I would like to eat them. I'm not specially a big fan of this band but the form of the helmets is quite recognizable to many people so many people could enjoy them.

I start thinking on the desing and I choose one of the helmets. The idea is to design it on Rhino and I find many models on 3D libraries. Finally with the help of Juanes Vallejo I decide to make a simple Lego model out a 2D design that I make on Adobe Illustrator.

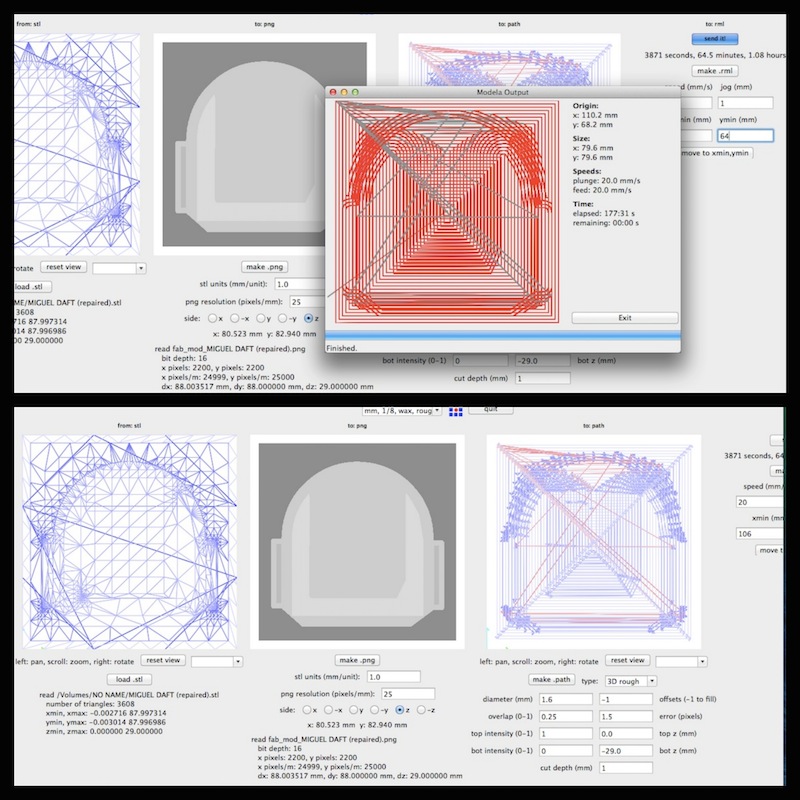

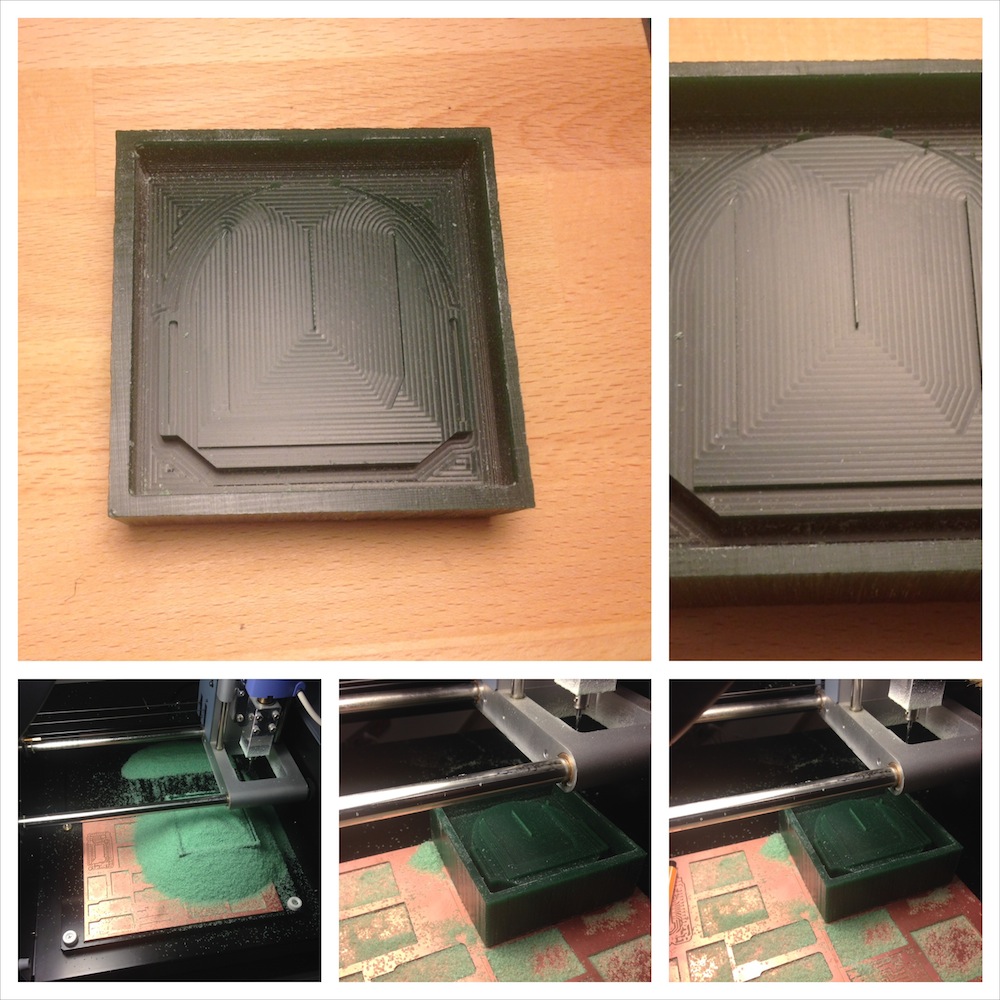

The illustrator model is exported to Rhino, and with the help of Juanes I make an .stl object. The .stl is imported into Fab modules and I make a rough cut with an 1/8" rounded drillbit. The process takes around 70 minutes.

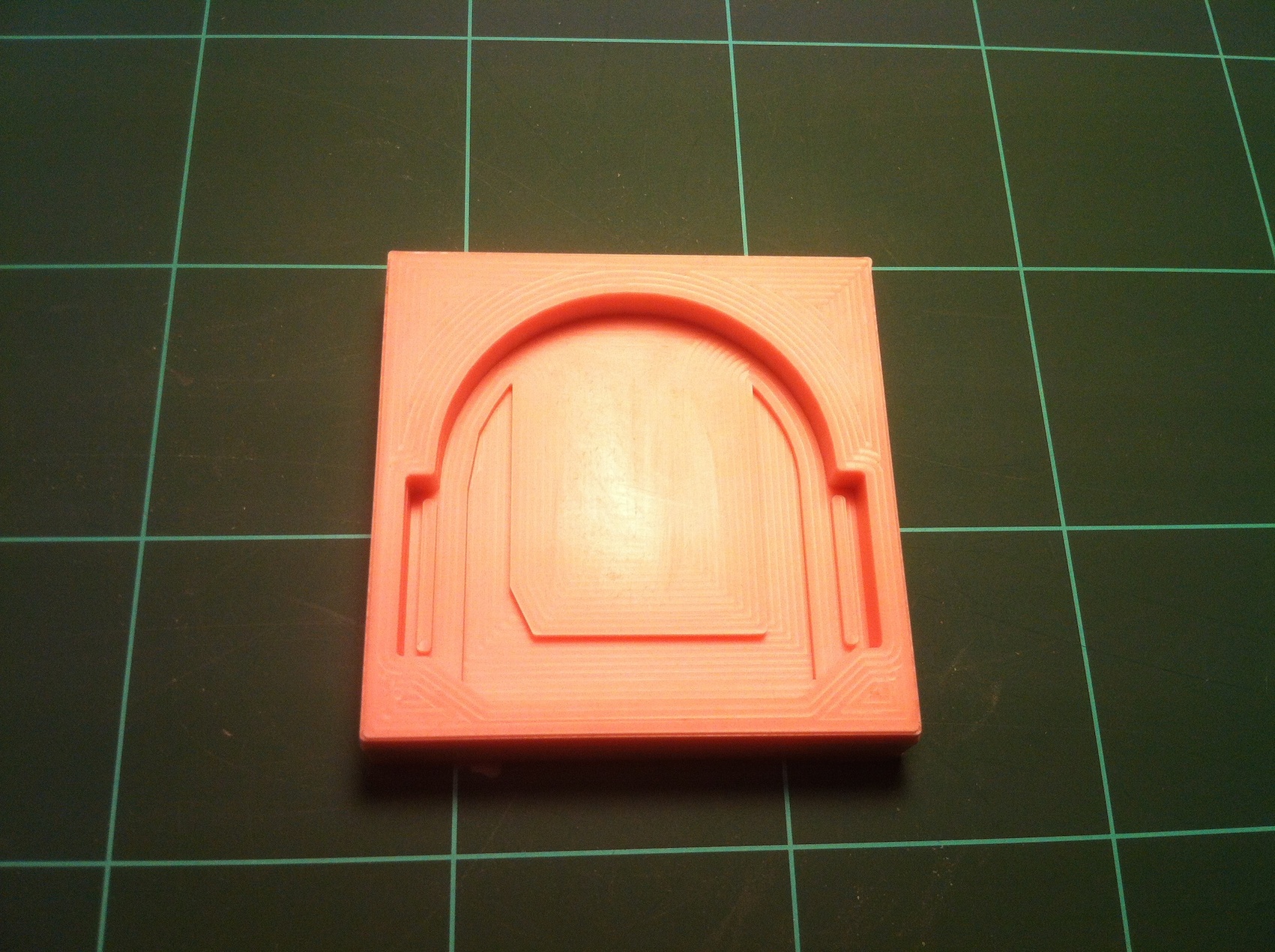

This is the final result:

To be continued:

I didn't have time to make the silicon mould so my work remains unfinished until next time I can go to the lab.

Food safe silicon mold

Some time later on I start doing the silicon mold for the chocolates. I am going to use a food safe silicon. After checking the instructions you have to calculate the volume of the mold and translate it into the proportions of the product A and B (base and catalyzer) which B is the eleventh part of the mold volume; A is ten parts.

Now it's time for mixing, we don't want bubbles in teh mixture so take your time. Once is properly mixed you can pour. I put something underneath the wax so the mold have some inclination, this helps the silicon to spread better.

Last step requires of vacuum, in our case we did a improvised system with a house vacuum cleaner, an IKEA vacuum bag, plastic bowls, a cardboard piece and two pens. We put the molds inside the plastic bowls and underneath them a couple of pens to left space for vacuum the air. It was basic method but it worked pretty well. Francisco was helping us in the whole process because we were not sure of it, at the end we were satisfied with the results.

Making the Chocolate

Last but not least, is time for melting the chocolate and pur it in the silicon mold. You have to give it some time to rest and this is the result:

Conclusion:

Molding and casting is an interesting technique for making repetitive objects. It works not so good with small parts but is very useful. One of the most difficult parts of the assignment was mixing products A and B. You have to be very careful that it won't appear undesired bubbles. It's pretty difficult to get rid of them without a vacuum device so remember to use one before starting this, otherwise you will experiment diffculties.

You can download all the files related to this week here.