COMPUTER-CONTROLLED MACHINING

Goals:

This week the goal is to make something big.

At the Lab:

For the moment we don't have a big CNC machine so I just need to figure out a design and then later on, I don't know when, we will cut the pieces. I also don't know the size of the material so I start thinking on what I want to do.

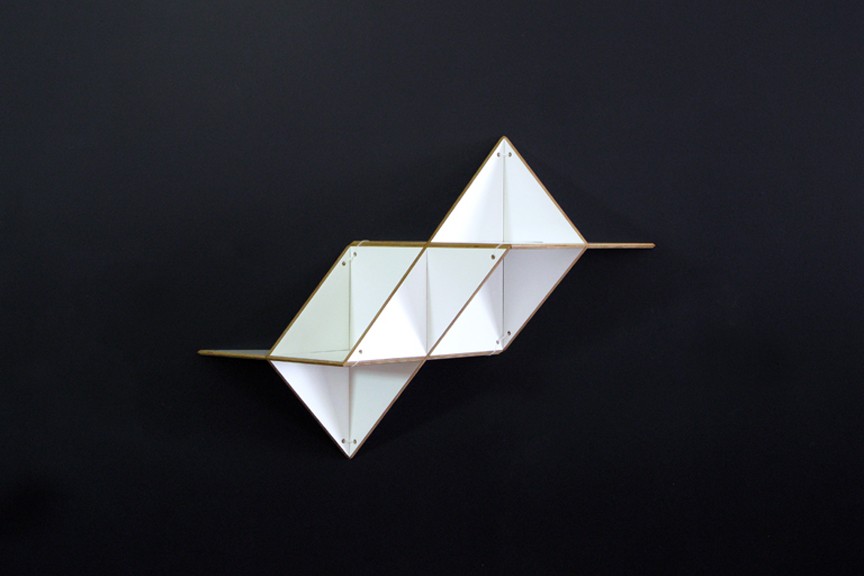

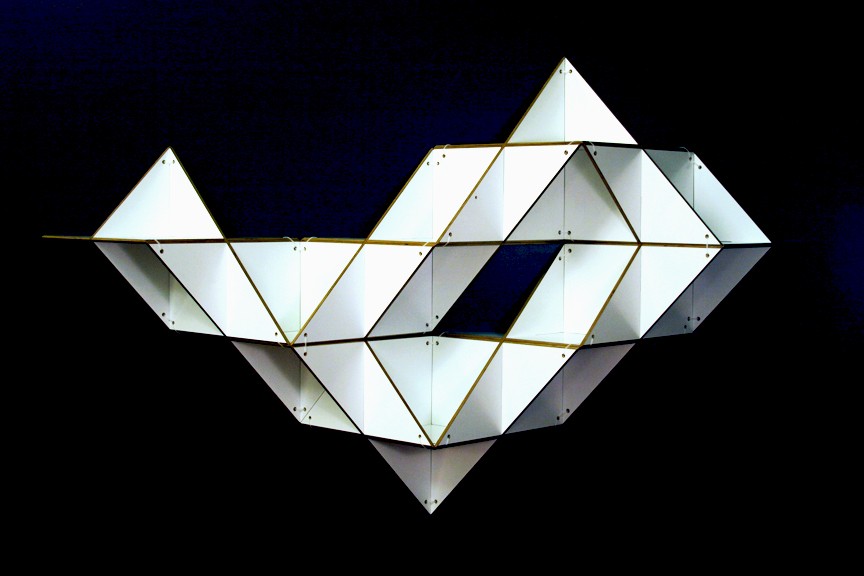

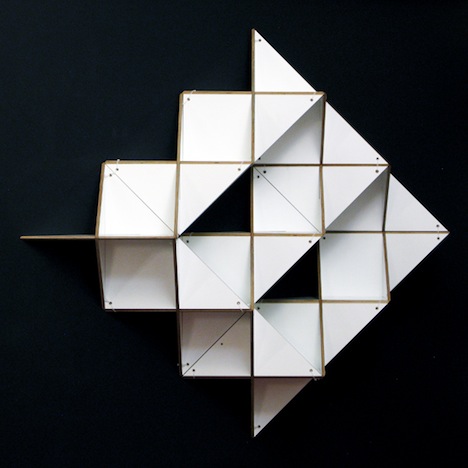

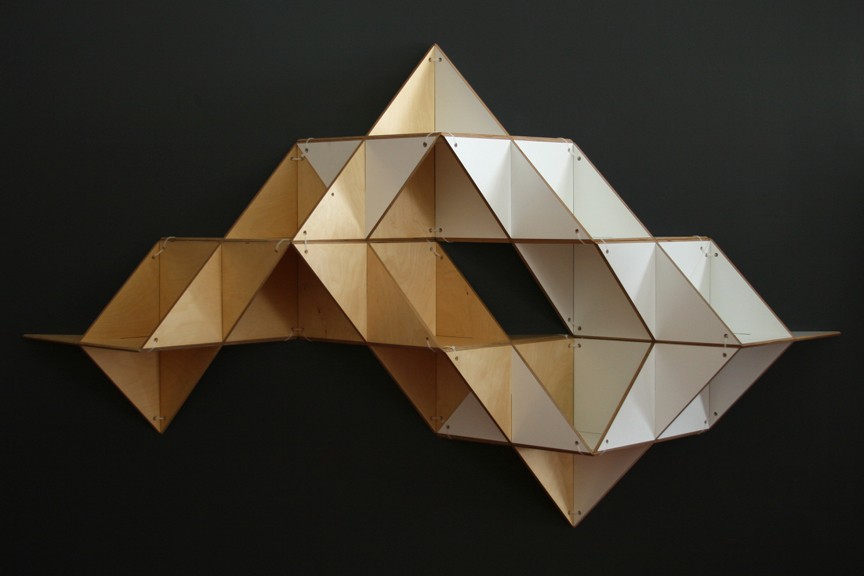

Some nice example of what I want to do:

I like the shelf designed by Jae Won Cho, a furniture designer from Los Angeles and I start thinking how the mesh of wood would be the best to fit. In order to be done, the shelf is based on a strong geometric shape, the triangle. I like the simplicity of the form and the nice result after fiting together all the elements.

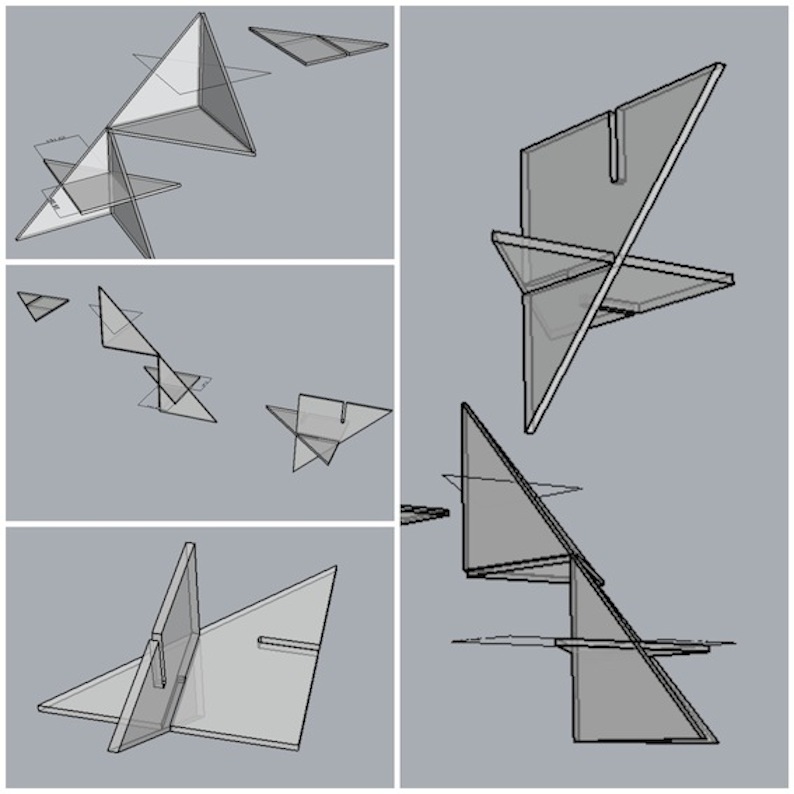

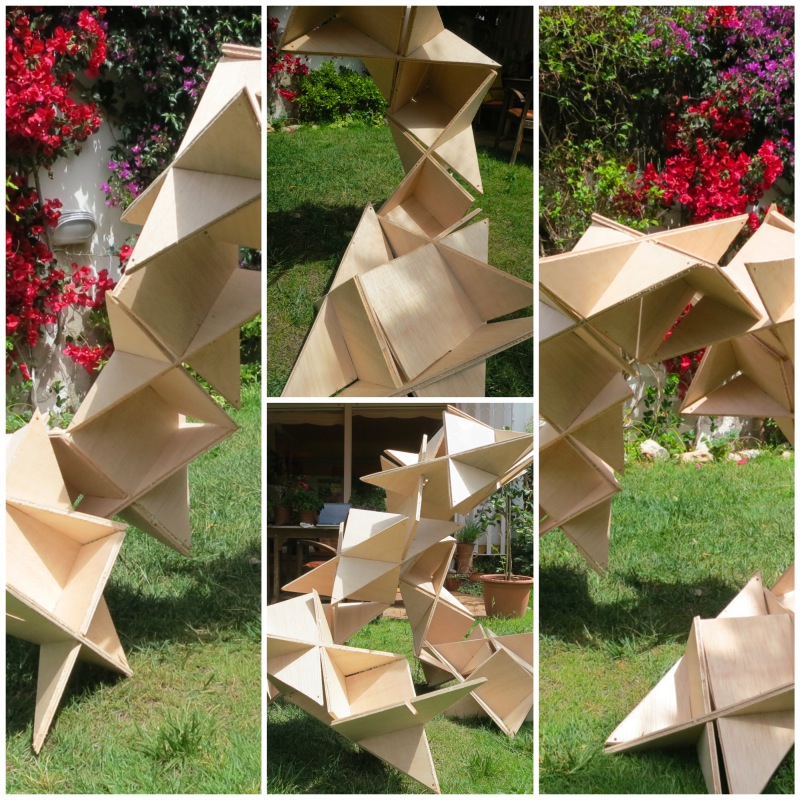

I would like to do something very similar. As you can see it can be very big, and it can be used as a shelf, as a table or anything you can imagine. These are some pics of the design in Rhino and also some others pics of the final work of the artist.

Now I'm writing again around 3 o 4 months later. Our lab is different in every single way and everything you can imagine to other labs. This is the first year of the Fab Academy in the Beach Lab Sitges. We all are learning: the students and the managers. We are nicely located in front of the beach which is just few meters away from all our machines: the Roland Modela, the 3D printer Ultimaker 2, the Full Spectrum Laser Cutter, the Shopbot, the.... did I say the Shopbot? … Well, actually we don't have a Shopbot.

For different reasons we don't have it. Instead of using a Shopbot we are planning to make a wall-positioned CNC machine which it will make similar functions as the Shopbot. It also will take a while to have it in the lab so we just need to wait.

Now I'm writing a month later after last paragraph. We are on mid may and still have to do the assignment. The wall-positioned CNC machine couldn't arrived.

So well, we have only just 2 weeks left for the final project presentation and instead of working on it, the whole Beach Lab is running out of time to find a spot in Fab Lab Barcelona to cut our pieces there. They kindly gave us an appointment but it did't work well for some of us. We needed time to set up the software and also in the middle of the cutting we had to stop the Shopbot because of schedules incompatibilties.

Preparing the cutting file, we should know the following:

Step 0:

Prepare the design using any CAD tool. You have to cut it as a .dxf. Polylines always. The machine should recognize all the connected lines. If you do the draw without polylines the machine will move more frequently and it will have some problems to cut well the wood at some points. This also means spending more time milling.

Step 1:

Modify the design using the constrains that you have in relation with material availability, this means a digital 2D model.

Step 2:

Import the file into the Shopbot Partworks as a file .sbp

Step 3:

Secure the pieces of material with screws

Step 4:

You have to calculate well the tolerances. Our wood is 20mm plywood so we have to adjust it to 20.10mm so all the pieces can fit well. In my case I didn't need any tabs but feel free to use if necessary.

Step 5:

Move the toolhead on the X and Y axis, then set zero for both axis. Zeroing axes.

Step 6:

Set zero for the Z axis using the metal plate.

Step 7:

Load the shopbot file created in Step 2 into the Shopbot editor. Then you have to press two green bottons, in the software and in the physical control of the spindle. Then in the software again.

Step 8:

Once the material is milled remove the milled parts from the workbench. Clean the waste and separe the scrap.

Step 11:

Assembly the pieces.

Cutting at the Fab Lab Barcelona:

So we came back again to Fab Lab Barcelona another day, and now it is only one week left to Final Presentation and we are still working on "Make something Big". At the end of the day my work was sent to the Shopbot but aparently it was a bad moment for Fab Lab Barcelona because they were closing and they stopped my work when it needed some more time.

My work was almost all cutted except the large traces of it. It was not milled till the end and I had to come back again, this time after final presentation.

I had to cut manually the plywood because the Shopbot was already busy with other works when I arrived. It was easy and fast using the jig saw . But of course the work was not so perfectly made as it should be. The internal traces of the triangles were well cutted with the CNC and fortunately once all the triangles were cutted they fit each other. All this would had not be necessary if the Shotbot had finished the work I sent. There was a lack of communication between me and the Fab Lab Barcelona and that is how I had to solve the situation.

Assembling:

After having all the triangles at home I changed my mind and I decided that I wanted to change the form of the shelf and make something different with it.

It turned into a decoration piece for gardens. You can easily put there watering cans or maybe some plants, lamps, even candles. A garden furniture that could be used on summer. It is definitely "something" and it is definitely "big". So now let's just hope that it doesn't rain.

The result is the following:

Conclusion:

Planing is useful. It is not good to stay in world of planing all the time because during that period you get stucked there in a loop and you don't make anything else. Under my opinion, the combination of planning in advance and non stop making things in the present is a key element for success. The assignment was not planned in optimal conditions and I had very little time to react, so I can say I almost could not do the assignment due to a bad planning.

I learned many things for this assignment. I learned about CNC machines, how they work, how you have to calibrate them and also that if you assemble in a different way you can get something pecualiar to what you expected in the begining. Doing things in a different way is also nice.

But I also learned about managing times and how running Fab Academy without having a key element is important for the students and their needs. Nothing in this assignment went easy at all but at the end, due to the good connections between Fab Labs and after suffering till the very last minute, things were acomplished and I could "make something big".

You can download all the files related to this week here.