This weeks

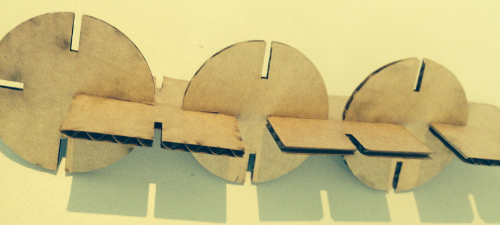

assignment is to create a press fit construction

kit using computer controlled cutting techniques to form

a series of 2D building blocks that can be friction fitted.

My project

I have decided to

explore making snap-fit boxes for the robot body in

preparation for my final project and a construction kit for

creating obstacles for the robots to maneuver around.

Skills learnt and things discovered

To

create a simplistic parametric design I initially started by

learning to use the clone function in Inkscape and after

watching several tutorials was able to adjust the press fit

notches. I started with a simple test using 3mm cardboard to

learn how to measure the Kerf. The tolerances of the press fit

notches can then be developed quickly and effectively

depending on the material type and the thicknesses available.

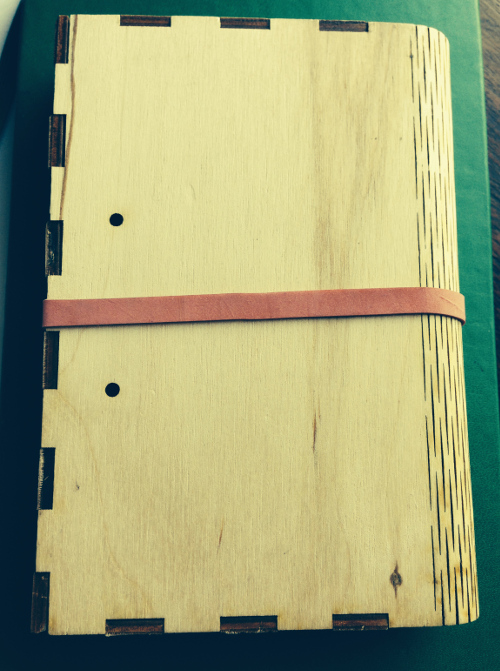

made pressfit box in ply worked

well, really like the hinge!

made pressfit box in ply worked

well, really like the hinge!

What worked well

The ply worked well as a material for snap-fit

design and the Tabbed Box extension for Inkscape was useful.

Thinking about my workflow around the laser cutter helped me

be more organized and productive. (see photo below

showing screen with inkscape model and laser cutter settings )

What didn’t work

Making

larger snap-fit boxes in cardboard. Retaining the press fit

was tricky. Managing the variable thickness of the plywood and

cardboard which required continuing tests to achieve a good

snapfit.

Tools used

Laser

cutter

Inkscape

and Tabbed box

Calipers

for measuring kerf and notches

Next steps

Lots

more practice!

Create

more complex shapes for the construction kit and try other

materials

Also

try other shapes and materials for creating a suitable

snap-fit body for the robot in the final project. Include text

and decorative design element

Useful references

www.instructables.com

previous

work by Fab Academy students - great reference for advice

Files for box

box files1

box2