My aims

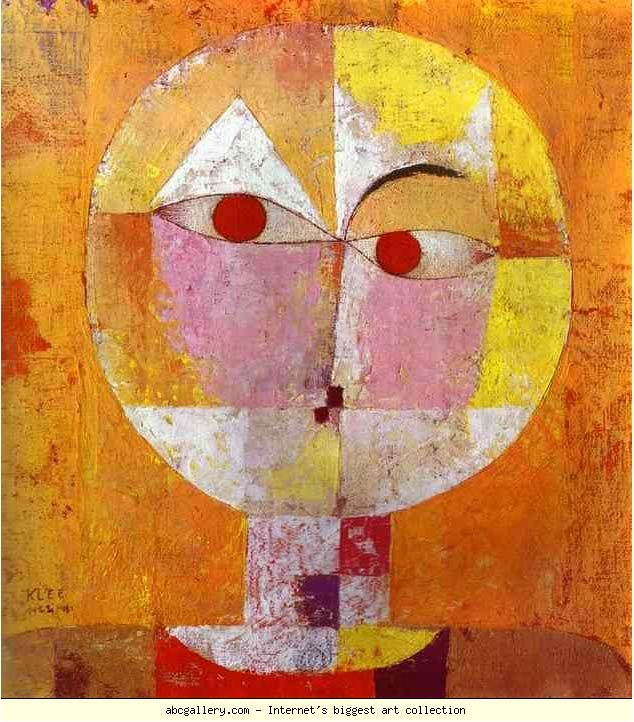

Research

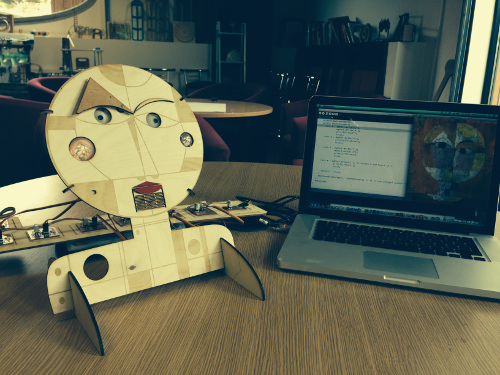

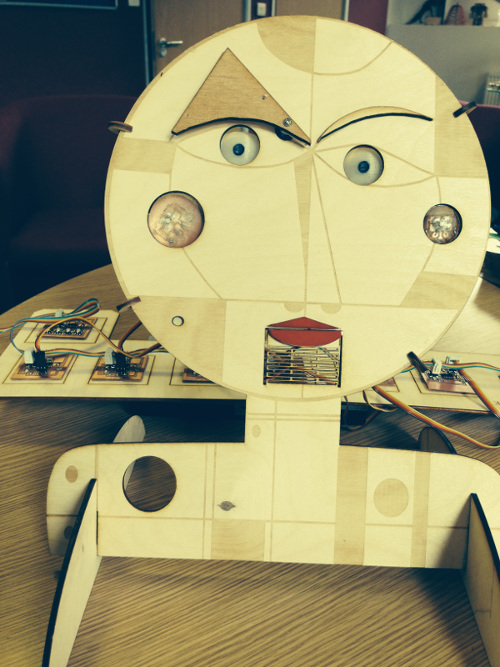

I had originally wanted

to make a robot but have become interested in robot faces,

expressions and communication so I thought I would take

inspiration from the wealth of art history in portrait painting

to help me explore the elements of facial expression and ways in

which a robotic face might communicate and how an audience might

interact with the face. I thought this would also provide me

with an interesting project to share with the students at school

and lots of opportunities to showcase the skills Ive been

learning on the Fab Academy course.

Features of the project

Research links

Lego Mindstorms

"Adorable robots that teach kids to code" - Play-i Bo and

Yana uses programming languages Blocky scratch Java and Python

Code Club

Code Academy

Science Buddies

http://www.sciencebuddies.org

Adafruit learning systems - http://learn.adafruit.com

Cynthia Breazeal The rise of personal robots

Ted Talks personal robots

ERWIN emotional robots University of Lincoln

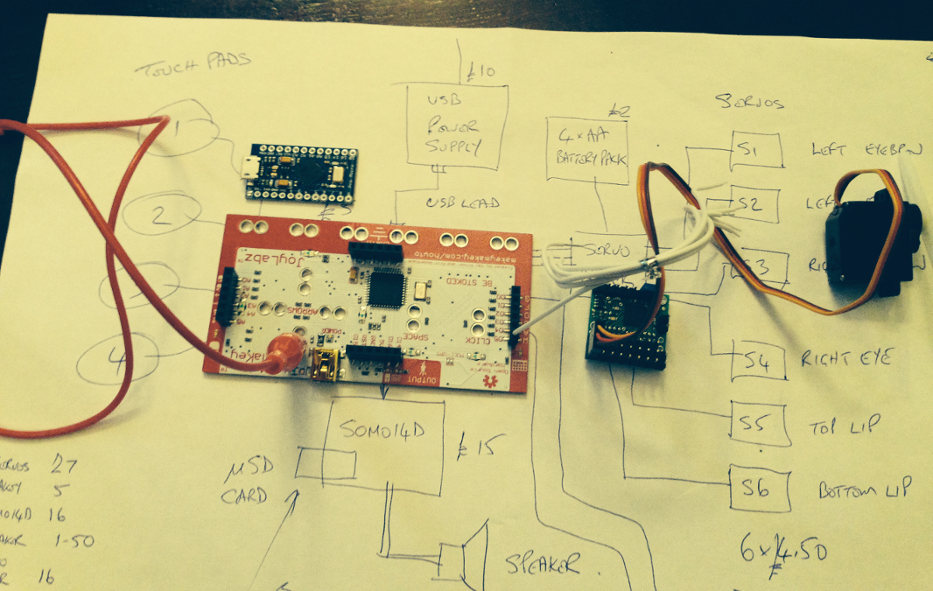

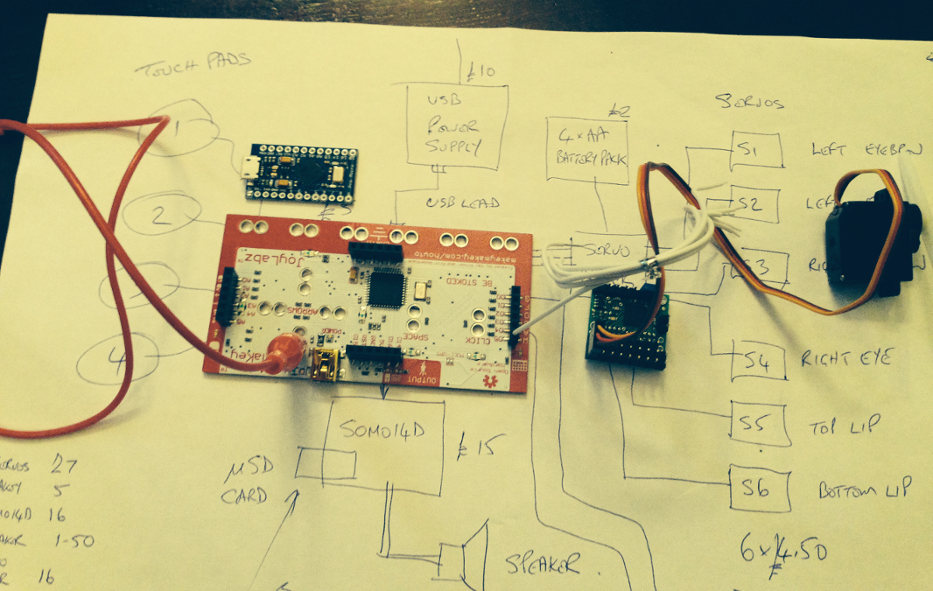

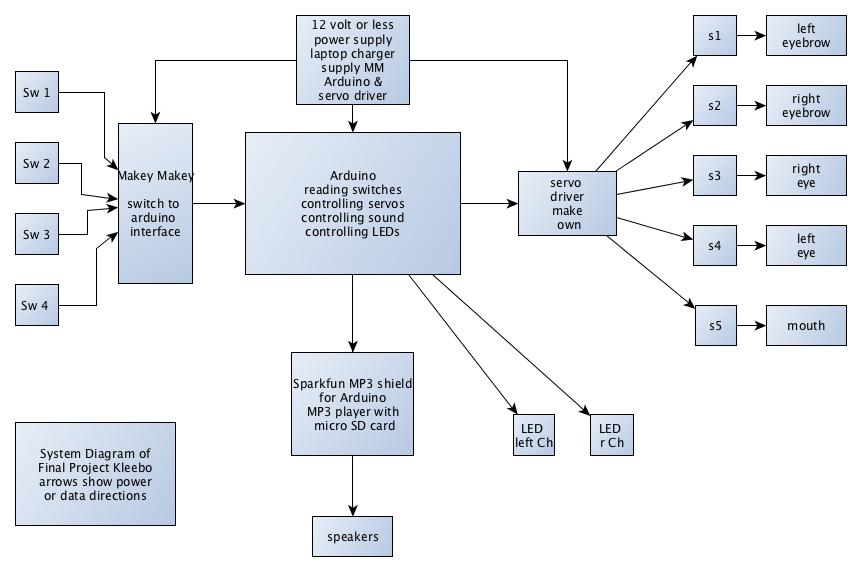

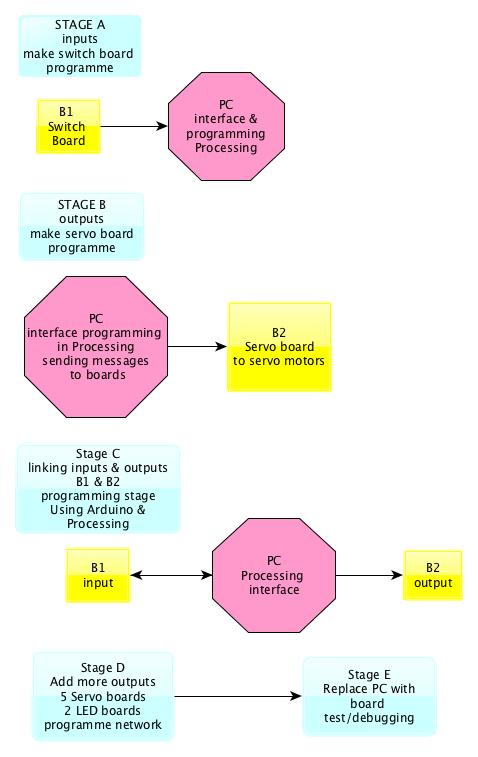

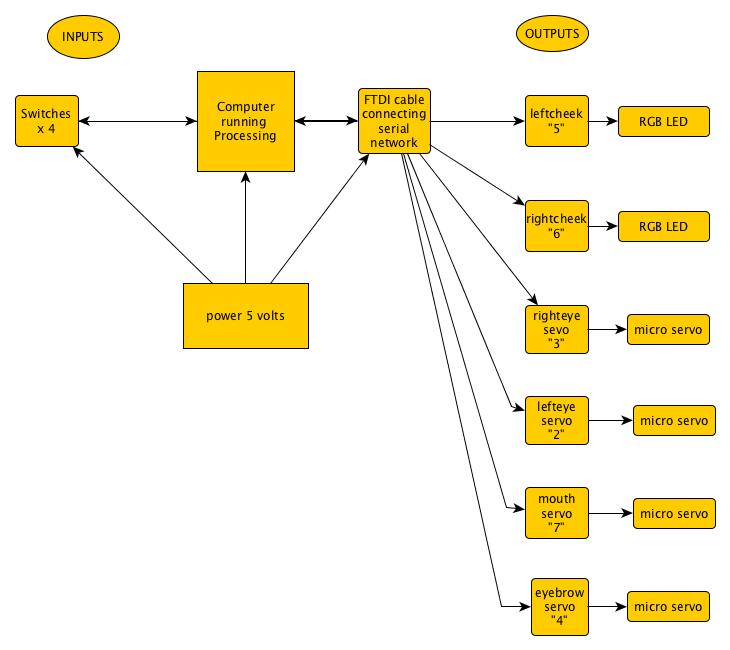

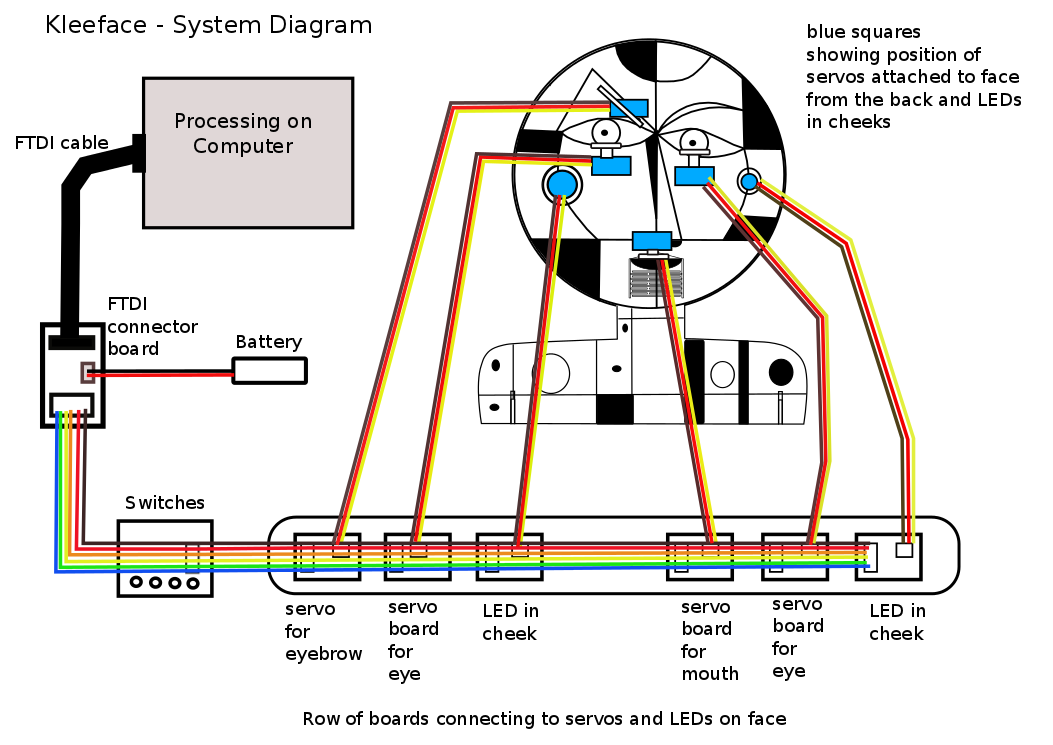

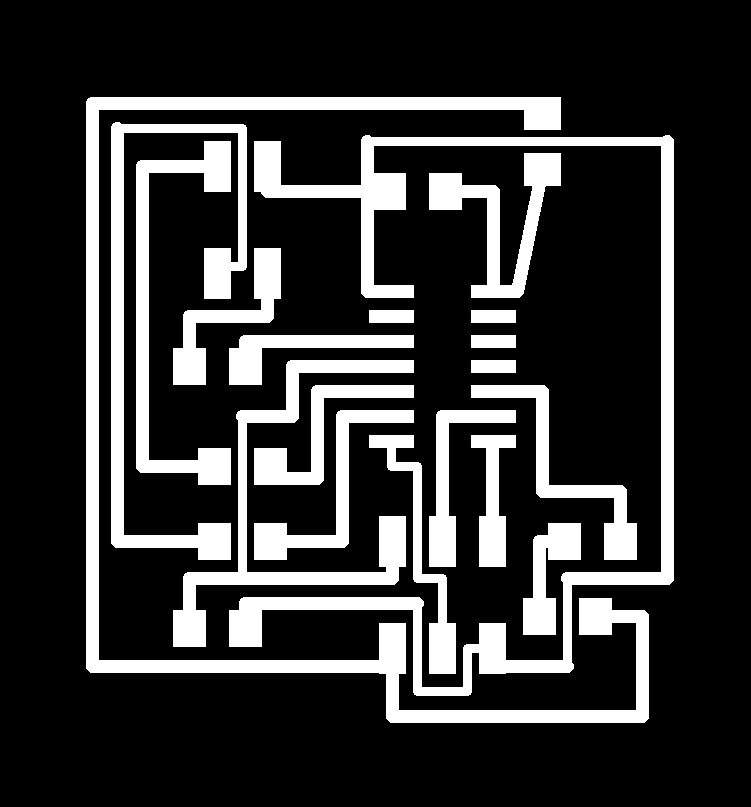

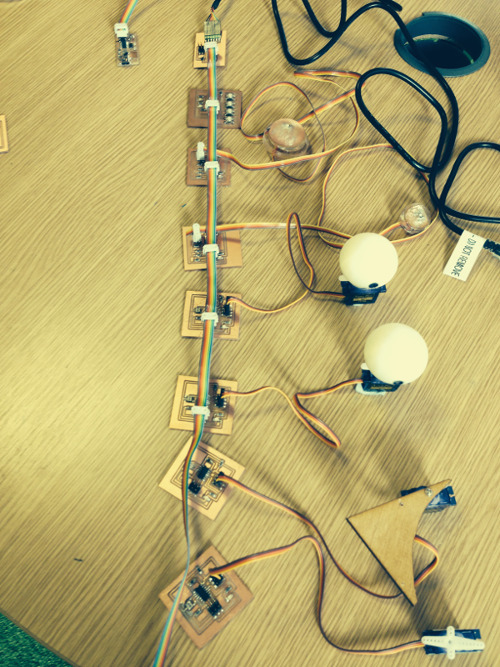

System Diagrams

Network

A

complex system with simple individual nodes. I have chosen this

system to be scalable allowing the addition of other nodes

creating a modular system easier to debug and make as each part

can be made independently. Hopefully the network will be easier

to manufacture, change and mend.

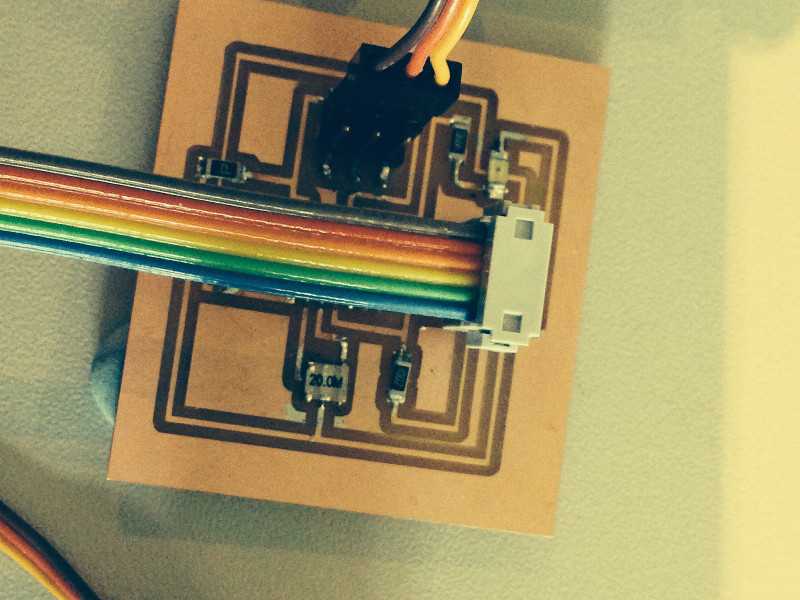

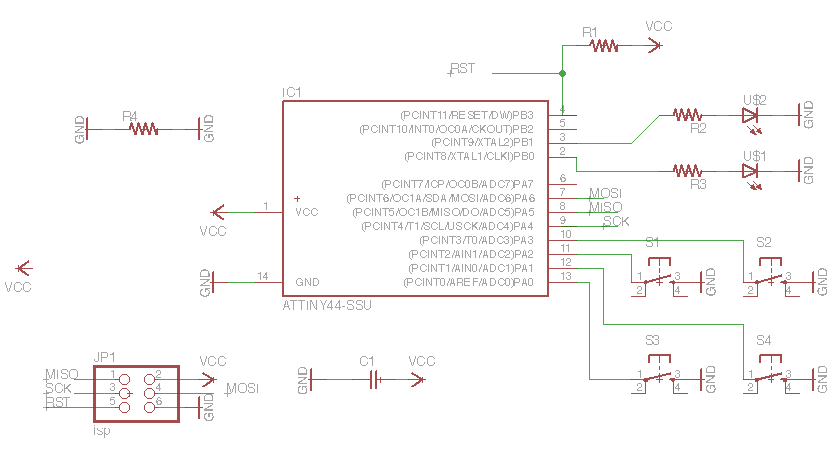

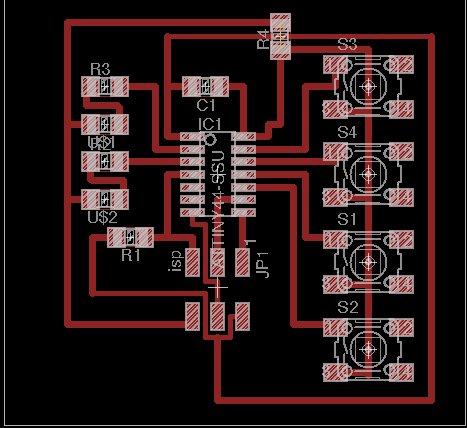

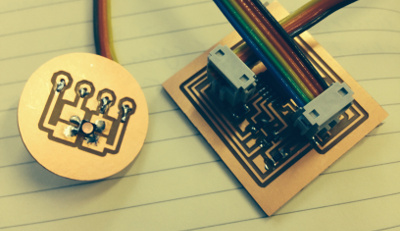

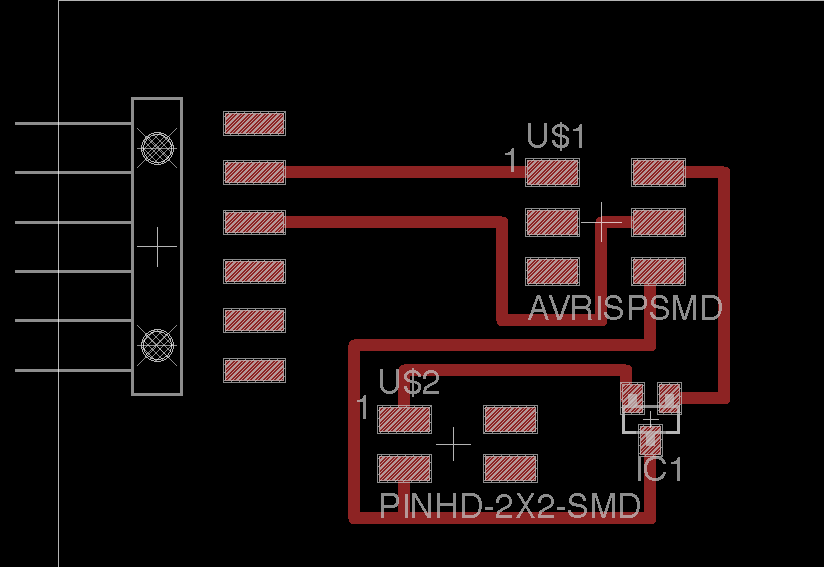

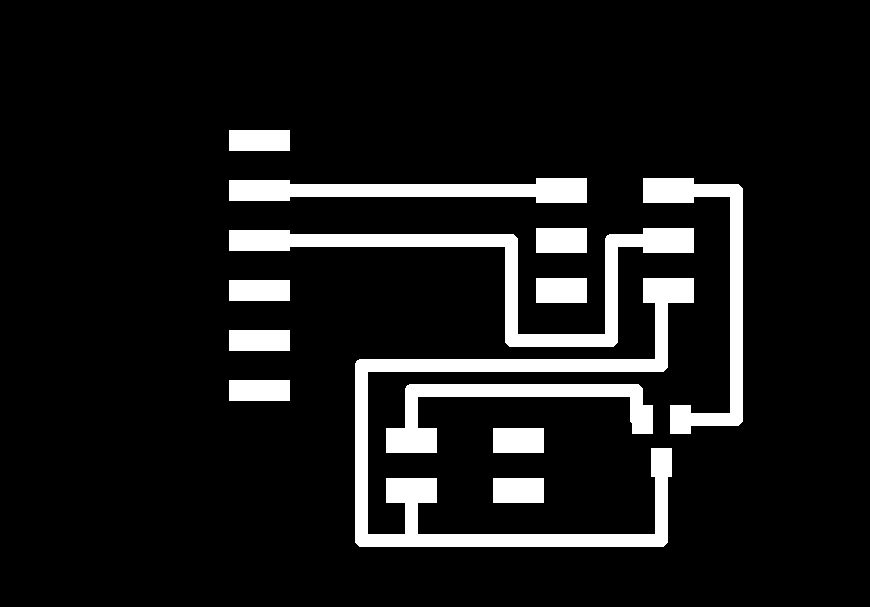

Board Designs

I

am making my boards using the Modella

|

Boards |

function

|

|||

|

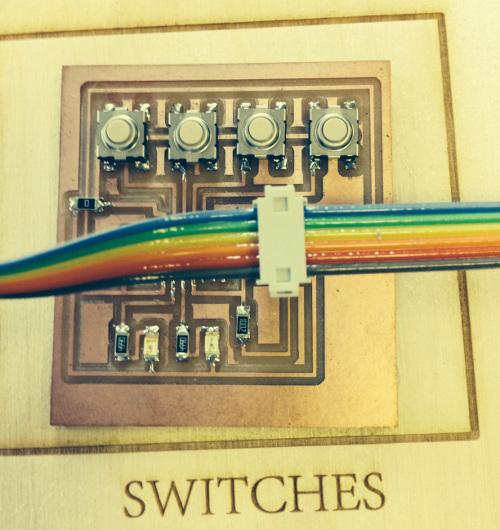

B1 |

Switches board with 4 buttons to be

interface |

|||

|

B2 x 4 |

Servo board x 4 to move parts of

face eyes,

mouth, eyebrows |

|||

|

B3 x 2 |

RGB LED board to light up cheeks |

|||

|

B4 x 2 |

Mini board for embedded LEDs |

|||

|

B5 |

Brain ATtiny 44 to replace computer and

make project stand alone |

|||

|

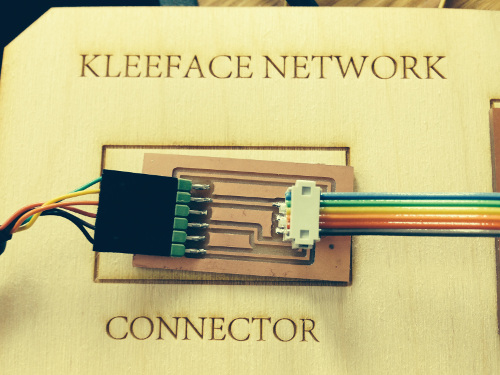

B6 |

FTDI connector with 2x3 header as bridge |

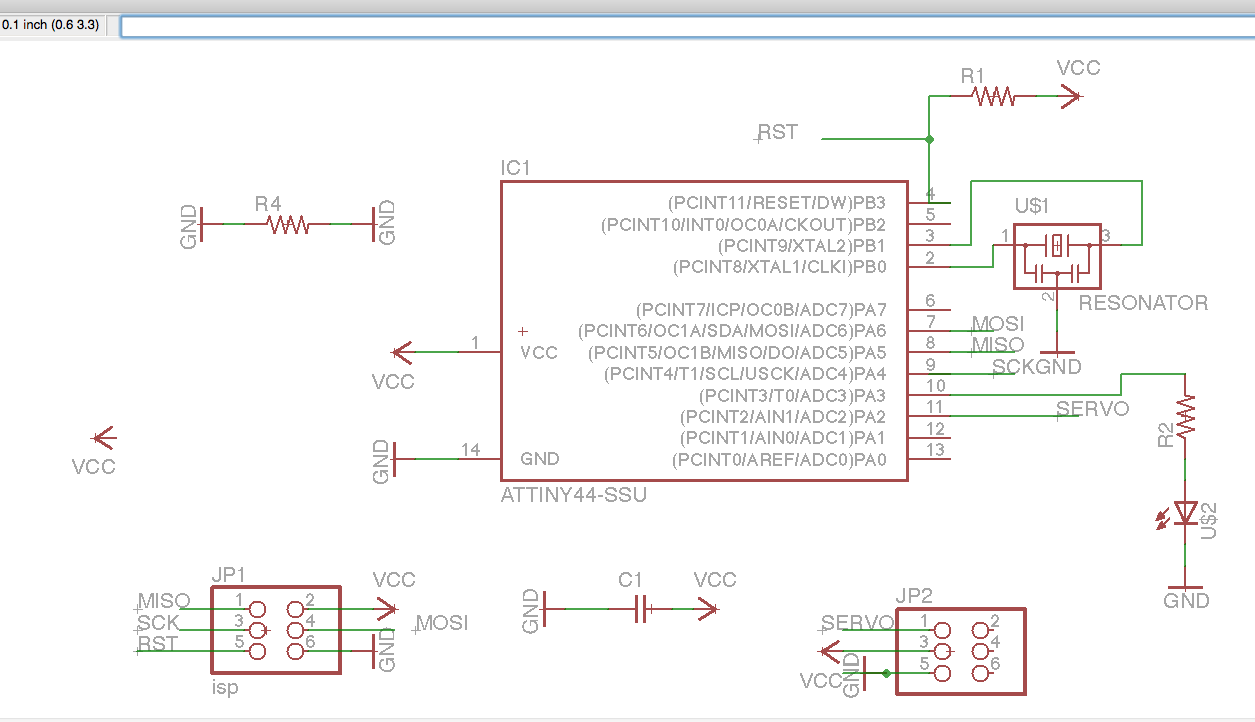

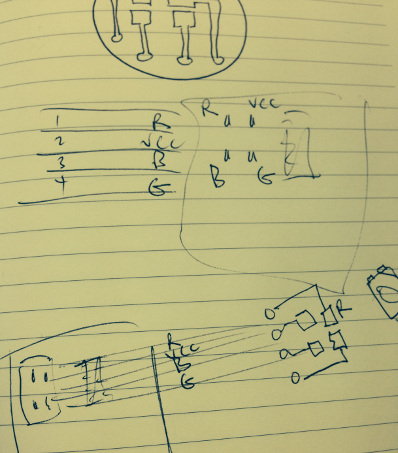

First

started by designing the servo board in Eagle, added LED, then

made, see below

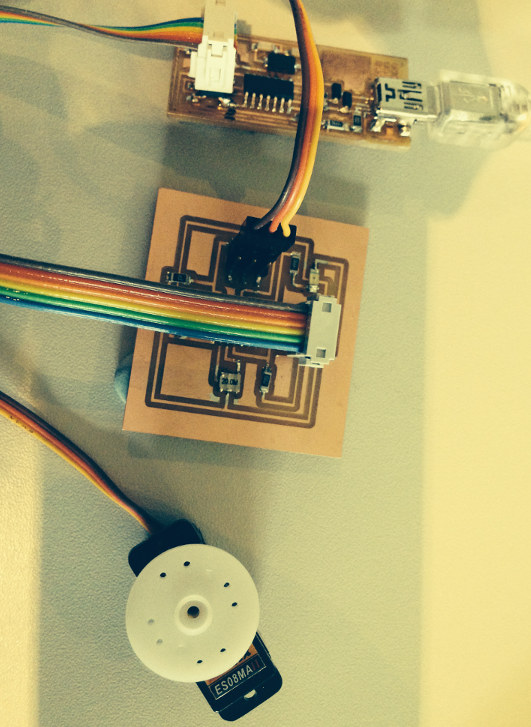

Servo Board

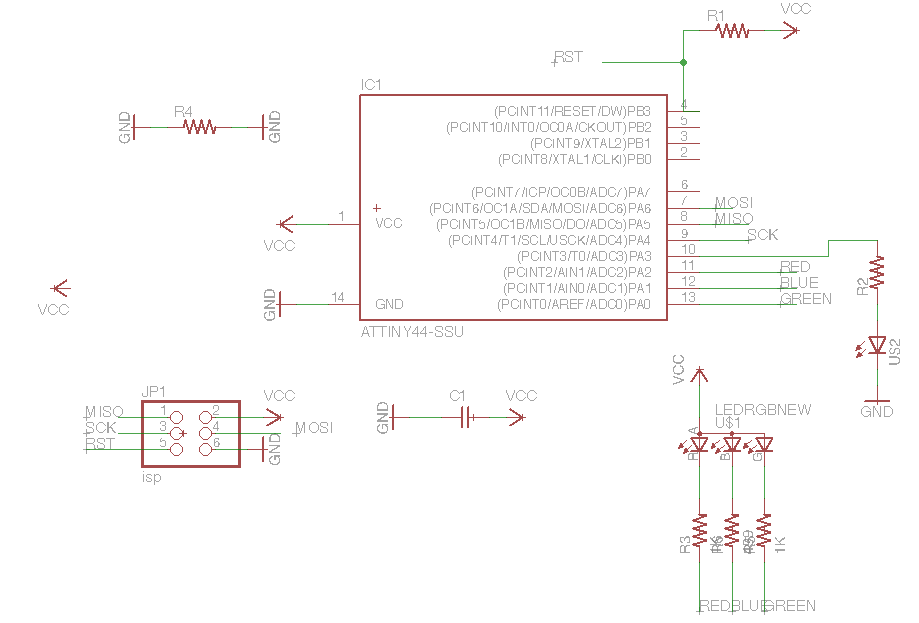

Servo Board - Schematic

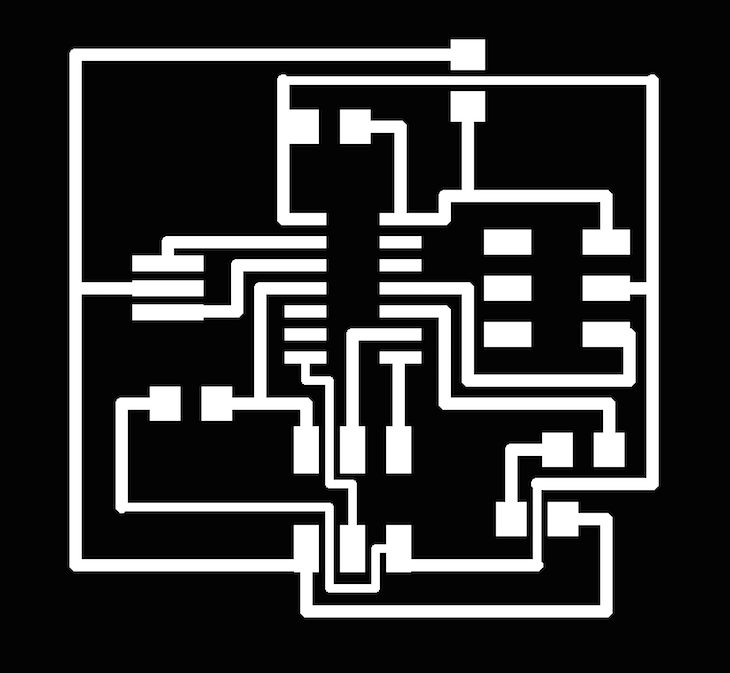

Traces

next

to programme in Arduino using my

FABISP - then to test the eye movement

sketch showing working out RGB LED

connections with header below

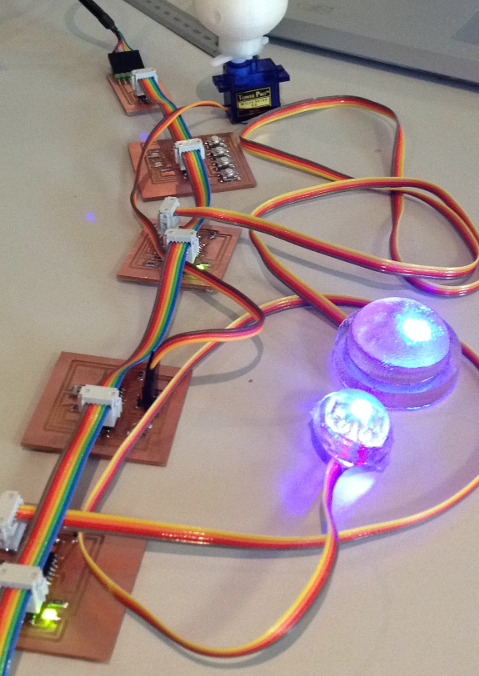

photo showing embedded LEDs working

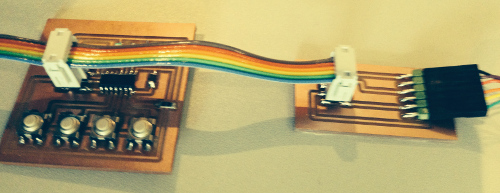

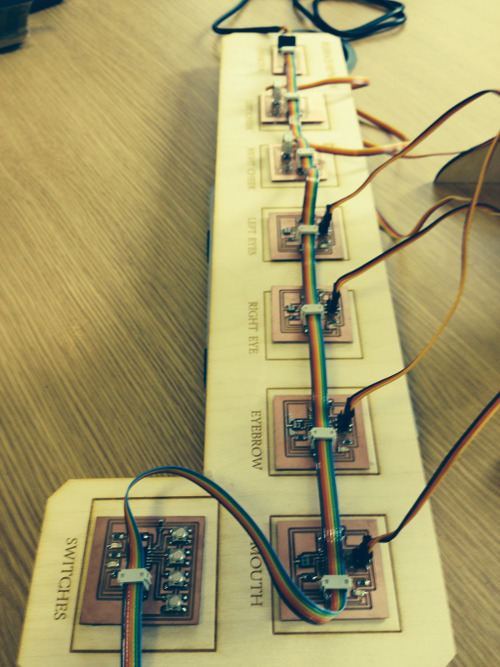

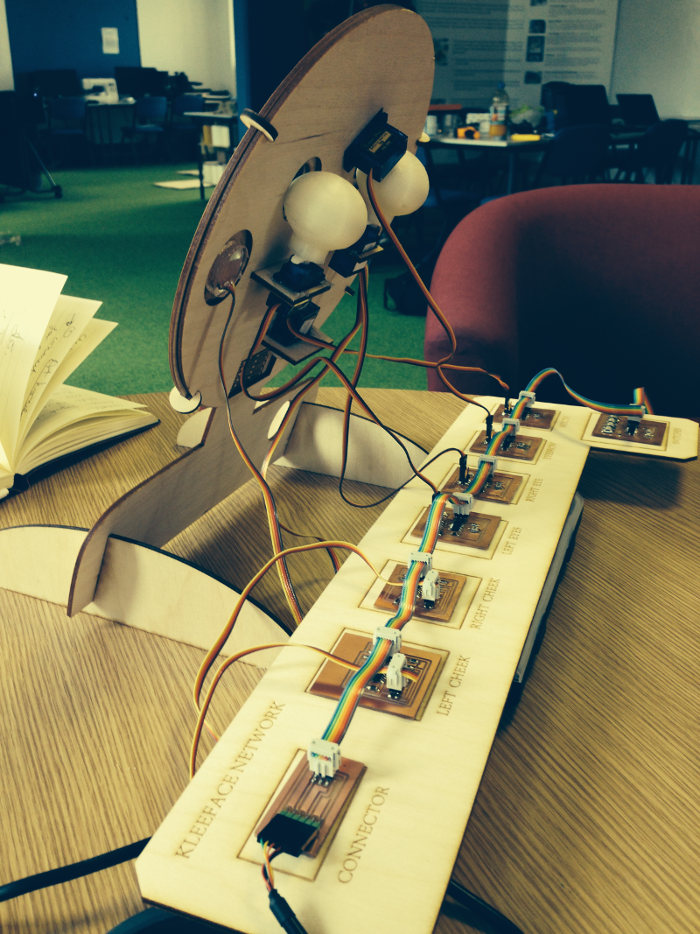

The network of

boards being programmed and tested below - all working, great!

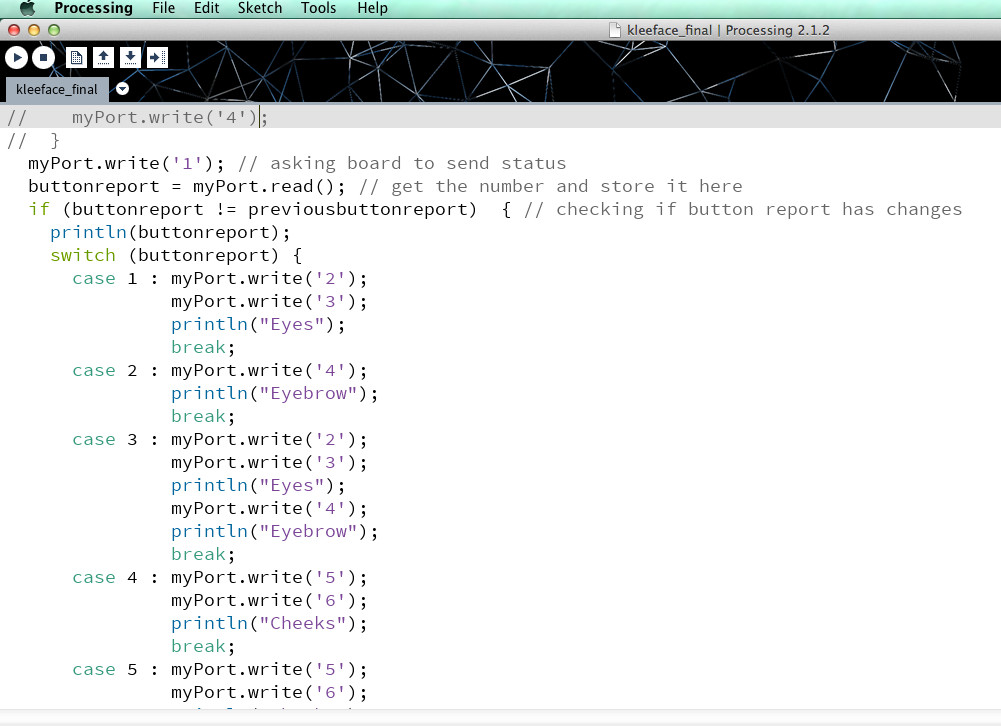

I

will use Arduino IDE to programme my boards and Processing to

communicate via my computer to each board.

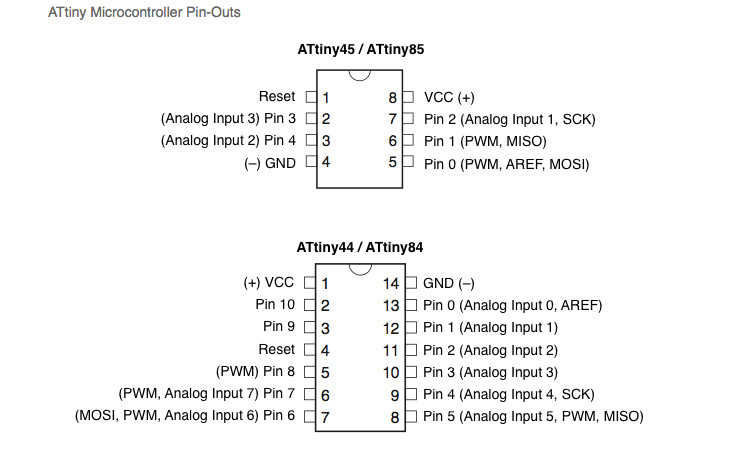

Useful

reference for programming ATtiny with Arduino Highlowtech.org/?p=1695

PLUS ATTINY PINOUTS BELOW

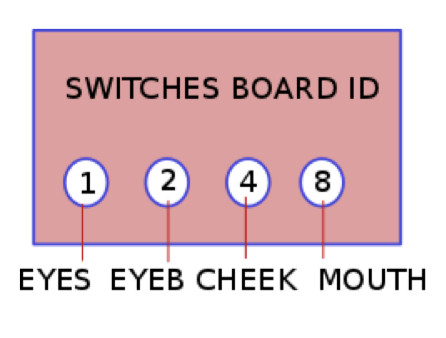

I used Binary numbers to workout the ID for the switches and

boards

Binary numbers to 15

|

0 |

0 |

0 |

0 |

0 |

|

0 |

0 |

0 |

1 |

1 |

|

0 |

0 |

1 |

0 |

2 |

|

0 |

0 |

1 |

1 |

3 |

|

0 |

1 |

0 |

0 |

4 |

|

0 |

1 |

0 |

1 |

5 |

|

0 |

1 |

1 |

0 |

6 |

|

0 |

1 |

1 |

1 |

7 |

|

1 |

0 |

0 |

0 |

8 |

|

1 |

0 |

0 |

1 |

9 |

|

1 |

0 |

1 |

0 |

10 |

|

1 |

0 |

1 |

1 |

11 |

|

1 |

1 |

0 |

0 |

12 |

|

1 |

1 |

0 |

1 |

13 |

| 1 |

1 |

1 |

0 |

14 |

|

1 |

1 |

1 |

1 |

15 |

|

BOARDS |

ID from

Processing |

|

Kleeface_left_eye |

2 |

|

Kleeface_right_eye |

3 |

|

Kleeface_right_cheek |

6 |

|

Kleeface_left_cheek |

5 |

|

Kleeface_eyebrow |

4 |

|

Kleeface_mouth |

7

|

|

Switches |

1

|

Commands Processing is sending out based on button

status. There are 15 possible combinations (see below)

|

BUTTON

NUMBER |

NAME

|

ID

of board sent from Processing |

|

1 |

EYES |

2

&3 |

|

2 |

EYEBROW |

4 |

|

3 |

EYES

&EYEBROW |

2

3 4 |

|

4 |

CHEEKS |

5

6 |

|

5 |

CHEEKS

& EYES |

2

3 5 6 |

|

6 |

CHEEKS & EYEBROW |

5

6 4 |

|

7 |

EYES

& EYEBROW & CHEEKS |

2

3 4 5 6 |

|

8 |

MOUTH |

7 |

|

9 |

MOUTH

& EYE |

2

3 7 |

|

10 |

EYEBROW

& MOUTH |

2

8 |

|

11 |

MOUTH

EYEBROW EYES |

8

2 1 |

|

12 |

MOUTH

CHEEKS |

5

6 7 |

|

13 |

MOUTH

CHEEKS EYES |

7

5 6 2

3 |

|

14 |

MOUTH

CHEEKS EYEBROW |

7

5 6 4 |

|

15 |

MOUTH

CHEEKS EYEBROW EYES |

2

3 4 5 6 7 |

| Kleeface_leftcheek_5 | as right cheek / they work

together

|

| Kleeface_switches_1 | switches |

| Kleeface_rightcheek_6 | leftcheek |

| Kleeface_LEservo-2

|

lefteye |

| Kleeface_REservo_3 | rEye3 |

| Kleeface_mouth_7 | mouth

arduino |

| Kleeface_eyebrow_4 | eyebrow_arduino |

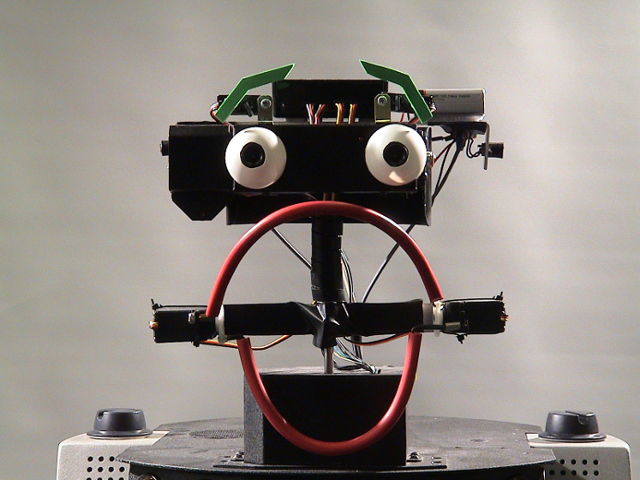

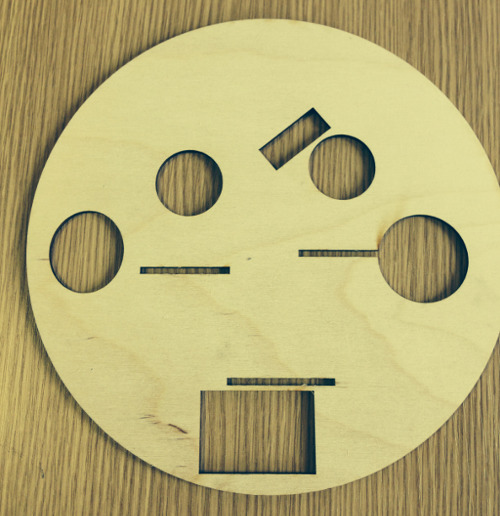

I

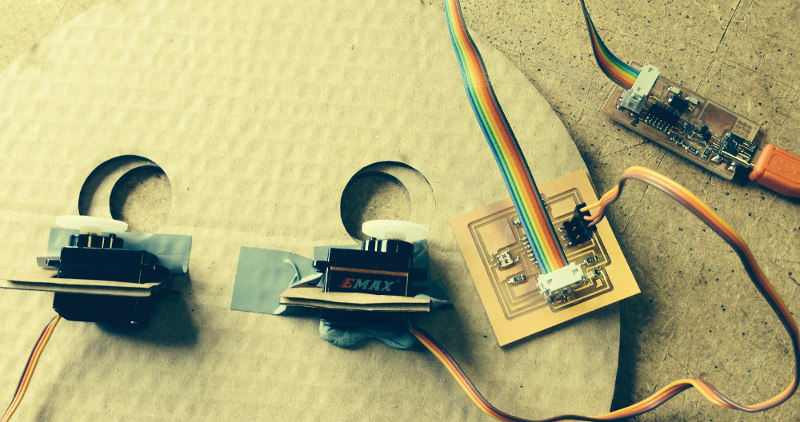

need to work out how to move the various parts of the face,

eyes, mouth, and eyebrows, using the servos. To achieve this I

have first to make a prototype face, 3D print the eyes,

think how to attach and position the servos, design and make my

own servo board so that I can test the movement of the eyes and

mouth.

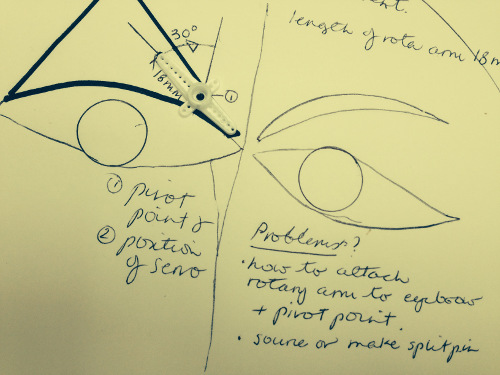

Problems to solve

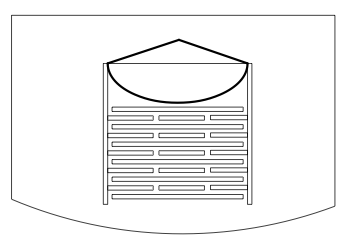

· Work out

flexures to move the mouth

· Work out pivot

points for eyebrows and servos

Work out position of eyes and servos

· In Rhino redraw

the back plate of face, position all the press-fit connectors to

hold servos so front and back of face match up

Useful website for

understanding how to use servos

http://www.societyofrobots.com/actuators_servos.shtml

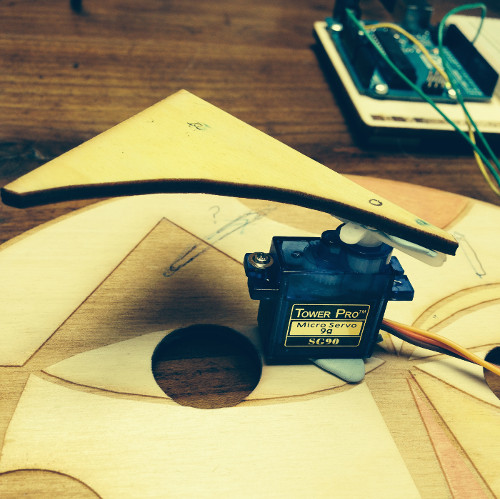

Positioning the 4 servos on face, next to think how to

attach them and test - testing movement

and position of eyebrow

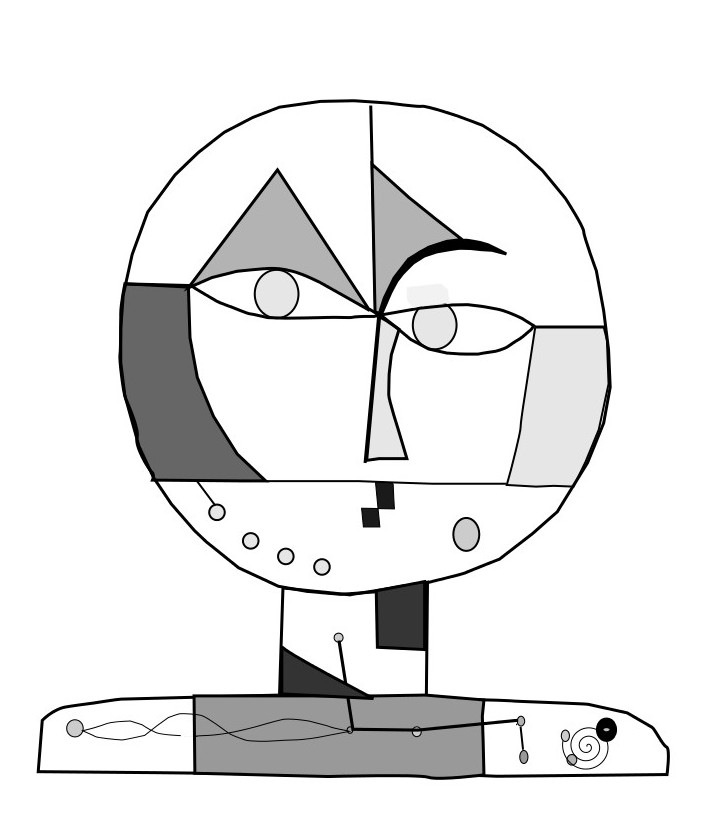

Fabrication

What needs to be designed and made?

|

Parts to be made |

Process used and decisions to be made |

|

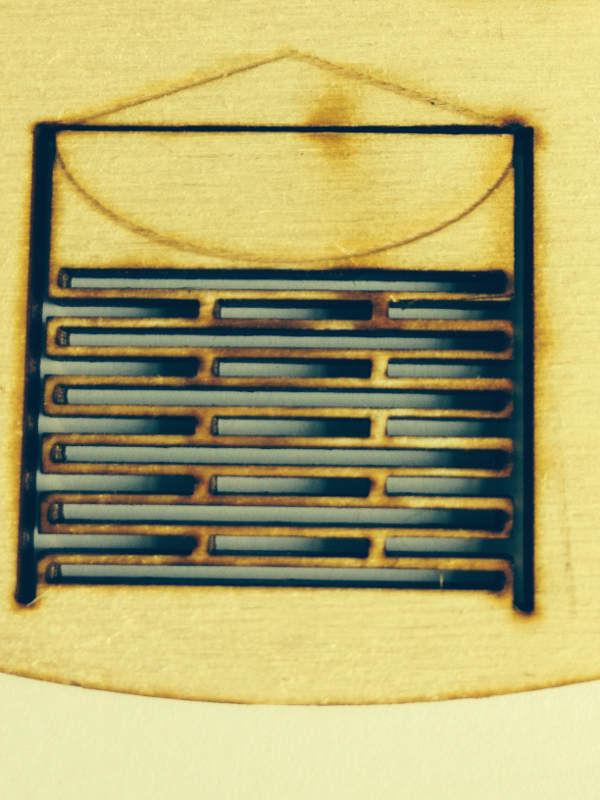

Face |

Lasercut with final changes to design

adding flexure to move mouth, cutout areas for cheeks to

be embedded Pivot points for servos, cut grove for arch

of servo for eyebrow |

|

Pressfit structure to hold face so able to

sit on the table |

Lasercut and decide on final design and

size, position of servos and pressfit connectors |

|

Pressfit connectors to hold servos |

Lasercut finalise size and position on

face Test press fit connectors to check it will

hold servos |

|

Eyes |

3d print in white with pupil improvements

to existing shape check size |

|

Eyebrows |

Lasercut, decide on movement, pivot point,

and how to connect them to the face, how to connect

eyebrows to servos and arc of movement |

|

Cheeks |

Draw up in Rhino cutout mold on shopbot

use epoxy resin to embed LED on mini board to allow for

connecting |

|

Mouth |

Laser cut mouth and think how to attach Flexure and servo to move mouth, where to

place servo? Consider pivot point |

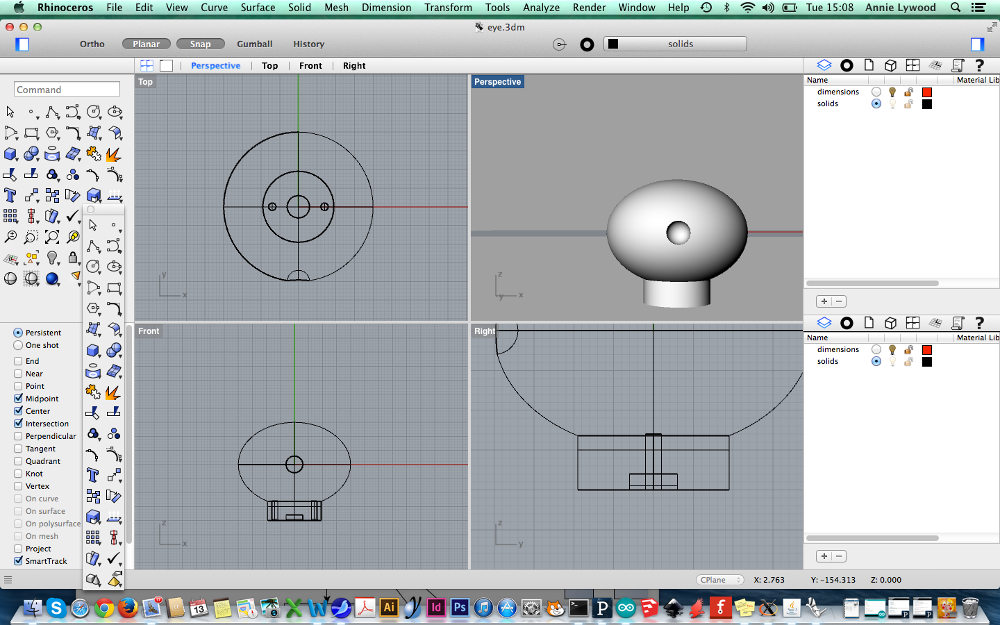

Started

with 3D print of eyes having drawn up design in Rhino to

appropriate dimensions

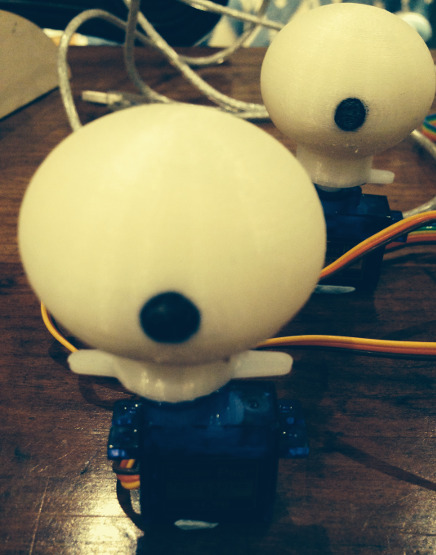

Attached

eyes

to servos to see how they fit on the face, is the shape

right? Printed in black as our only option so then needed to

source other colours and consider how to achieve a better

quality finish

First prototype of eyes

Second prototype of eyes,

resized and in white

Molds

for cheeks and embedded LEDs

Started

with drawing cheeks in Rhino using measurements from the face

and then cut out the mold using the Shopbot. This all went very

smoothly.

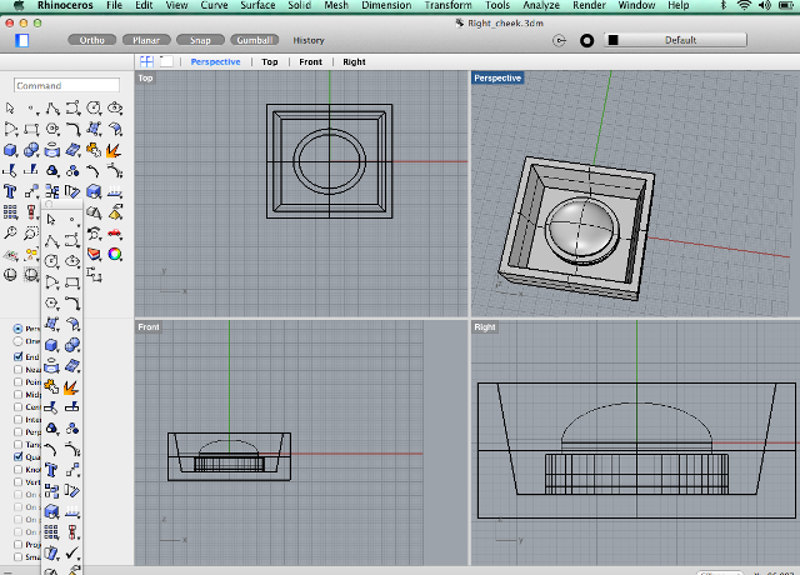

Backplate

for face

Thought

of simple ways to connect the servos so they are secure and

dont interfere with the design of the face. My concern at the

moment is that they will be heavy so stability of the structure

is paramount. My solution at the moment is to add a back plate

to the face which all the servos and linkages can be attached

using pressfit connectors. This has required lots of

testing to get all the parts and lasercuts in place. I found

drawing up the back plate in Rhino more accurate and easier to

measure than Inkscape.

Future Plans for Kleeboo

Files

for final Project

Fabrication

stl file left

cheek Rhino

stl file right

cheek Rhino

files 3D printing

eye Rhino

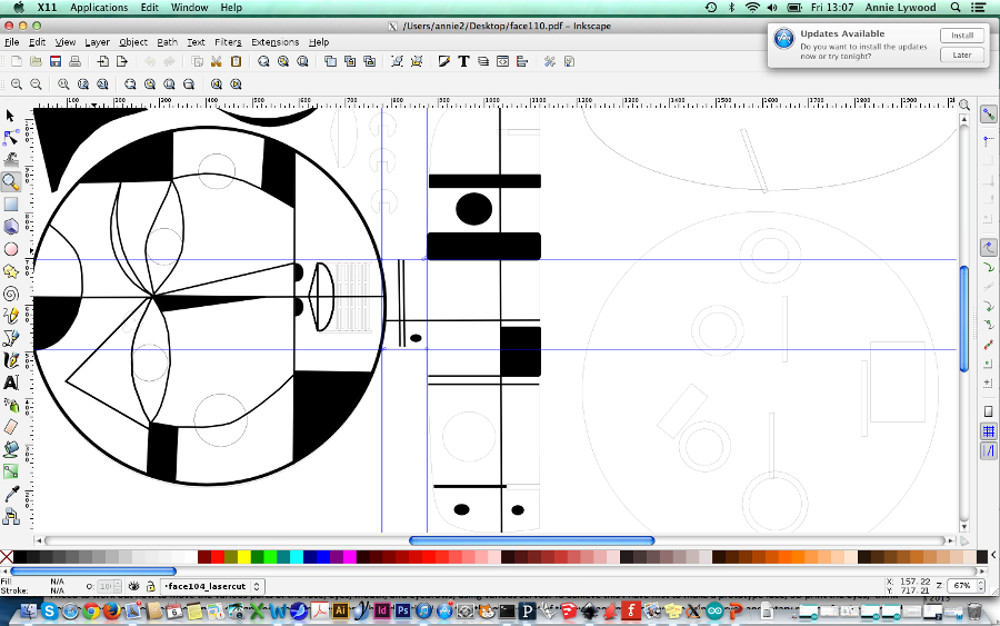

files pdf face inkscape

for laser cutting

Programming files

Arduino IDE

programs

eyebrow servo

programs eye

servo

programs

mouth servo

program RGB

LED cheek

program RGB

cheek

Processing

processing

Eagle

files for Boards

Servos

eagle files

servosch

RGB

LED

FTDI Connector

FTDI connector sch

FTDI

connector brd